Basic dye wastewater purifying treatment system

A basic dye and purification treatment technology, which is applied in energy wastewater treatment, textile industry wastewater treatment, water/sewage treatment, etc., can solve the problems of high cost and low efficiency, achieve high-efficiency treatment, strong biodegradability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

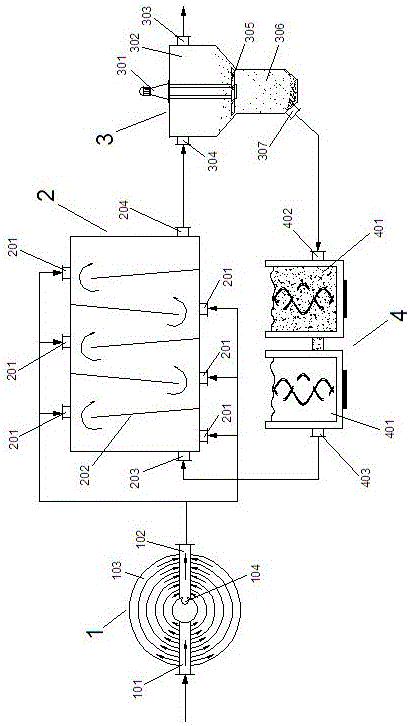

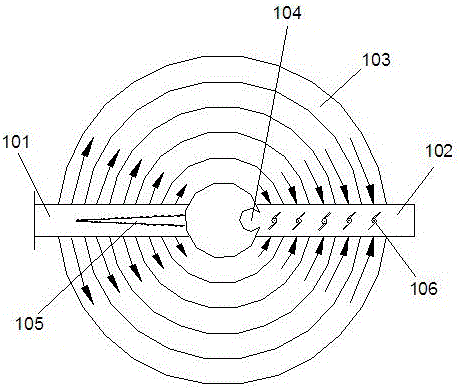

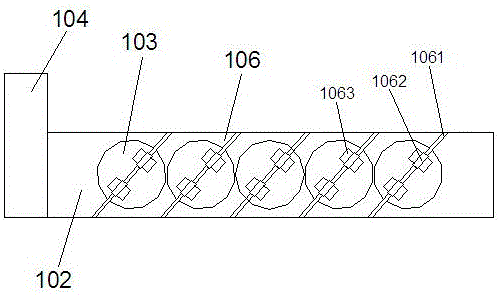

[0048] Such as figure 1 As shown, this embodiment is composed of an annular homogeneous tank 1, a catalytic reaction tank 2, a grit chamber 3 and a purification treatment system. The acid scarlet dye waste water enters the annular homogeneous tank 1 from the water inlet pipe 101, and the hydraulic retention time is 4h; 30wt.%H 2 o 2 After the hydrogen peroxide enters the pipe 104 into the ring-shaped homogeneous pool 1 (i.e. the water outlet pipe 102), the two are pre-mixed and enter the catalytic reaction pool 2, and the recycled catalyst inlet 203 enters the catalytic reaction pool 2, and the residence time is 20 minutes. . The degraded effluent is subjected to liquid-solid separation in the grit chamber 3, the impeller speed is 5r / min, the hydraulic retention time is 45S, and the clarified effluent flows out from the clean water outlet 303, where samples can be taken for testing. The separated catalyst enters the purification treatment system with H 2 O is the cleaning ...

Embodiment 2

[0052] Unit operation and catalyzer are with embodiment 1;

[0053] The concentration of acid scarlet dye wastewater is 1kg / t, 30wt.% H 2 o 2 The dosage is 2kg / t, the dosage of the catalyst is 2.5kg / t, it can be recycled, and the pH value is 10. The effluent was sampled by spectrophotometry and the degradation rate of acid scarlet was 65.6%.

Embodiment 3

[0055] Unit operation and catalyzer are with embodiment 1;

[0056] The concentration of acid scarlet dye wastewater is 1kg / t, 30wt.% H 2 o 2 The dosage is 2kg / t, the dosage of the catalyst is 2.5kg / t, it can be recycled, and the pH value is 7. The effluent was sampled by spectrophotometry and the degradation rate of acid scarlet was 22.3%. Prolong the residence time of sewage in the catalytic reaction tank 2 to 30min, and the degradation rate of acid scarlet is 30.1%. If the residence time is further extended, a higher degradation rate can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com