Industrial preparation method and application of recombinant interferon Alpha1

A technology of porcine interferon and repeated operations, which is applied in the fields of genetic engineering and protein purification, can solve the problems of lowering the specific activity rate of recombinant proteins, unqualified product quality, and affecting yield, etc. high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

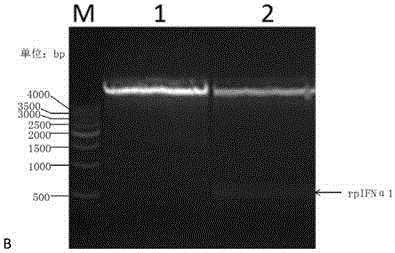

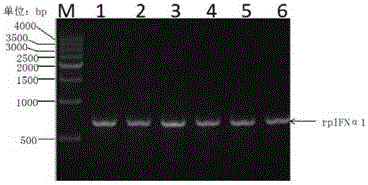

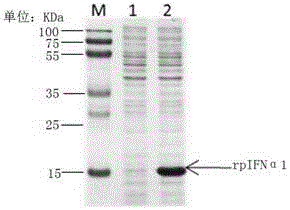

[0040] Example 1 Construction and expression identification of rpIFNα1 Escherichia coli strain

[0041] The inventor has previously completed the codon optimization and mRNA free energy optimization of the rpIFNα1 gene for Escherichia coli, and inserted the optimized rpIFNα1 gene into the pET21b vector to construct a recombinant expression plasmid, denoted as pET21b-rpIFNα1; the expression plasmid pET21b-rpIFNα1 It was introduced into the expression host of E. coli BL21(DE3) (denoted as BL21(DE3)-pET21b-rpIFNα1) by means of molecular cloning and high-efficiency protein expression was achieved, as described in the patent (application number: 201310025176.8). To clone the rpIFNα1 gene from the pET21b vector into pET28a, see the following steps:

[0042] 1. Take glycerol tubes of BL21(DE3)-pET21b-rpIFNα1 and DH5α-pET28a (preserved in our laboratory) strains frozen in a -80°C refrigerator, and inoculate them in LB liquid medium containing 100 μg / mL ampicillin after thawing. After...

Embodiment 2

[0049] Example 2 High-density fermentation of rpIFNα1

[0050] This example mainly describes the high-density fermentation process of BL21(DE3)-pET28a-rpIFNα1 strain. In the fermentation process, glucose and glycerol with clear components are used as the carbon source for cell metabolism, and diammonium hydrogen phosphate is used as nitrogen for cell metabolism. source; since the use of compound media similar to yeast powder and peptone is avoided, the instability between batches caused by compound nitrogen / carbon sources is avoided, so the media composition of different fermentation batches can be easily achieved control, and because of the low cost of glucose and glycerol, the overall cost of the fermentation process is well controlled. After the fermentation, the OD600 of the fermentation cells can reach between 90-100, and the expression of the target protein can reach more than 1.5g / L.

preparation example 1

[0051]Preparation example 1 concrete steps are as follows:

[0052] 1. Preparation of fermented seed liquid: inoculate the rpIFNα1 Escherichia coli strain cryopreservation tube constructed in Example 1 into LB solid medium containing 50 μg / mL kanamycin using the method of three-section line, and overnight at 37°C culture for activation;

[0053] 2. Pick a single colony with a plump shape and a moderate size from the solid medium and inoculate it into LB liquid medium containing 50 μg / mL kanamycin, and culture it on a shaker at 220 rpm at 37°C for 8 hours. This is the primary seed solution.

[0054] 3. Transfer the primary seed solution in step 2 to fresh LB liquid medium containing 50 μg / mL kanamycin according to the inoculum amount of 1%, and culture it on a shaker at 37°C and 220 rpm until OD600≈3-5 Between, this is the preparation of secondary seed solution.

[0055] 4. Composition of batch fermentation medium: citric acid monohydrate 1.5g / L, potassium dihydrogen phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com