Preparation method of Pt/graphene oxide/ferric oxide catalyst used for enhancing room temperature catalytic oxidation activity of formaldehyde

A technology of catalytic oxidation and graphene, applied in the field of nanomaterials, can solve the problems of low activity and inability to meet, and achieve the effect of enhanced adsorption and effective decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

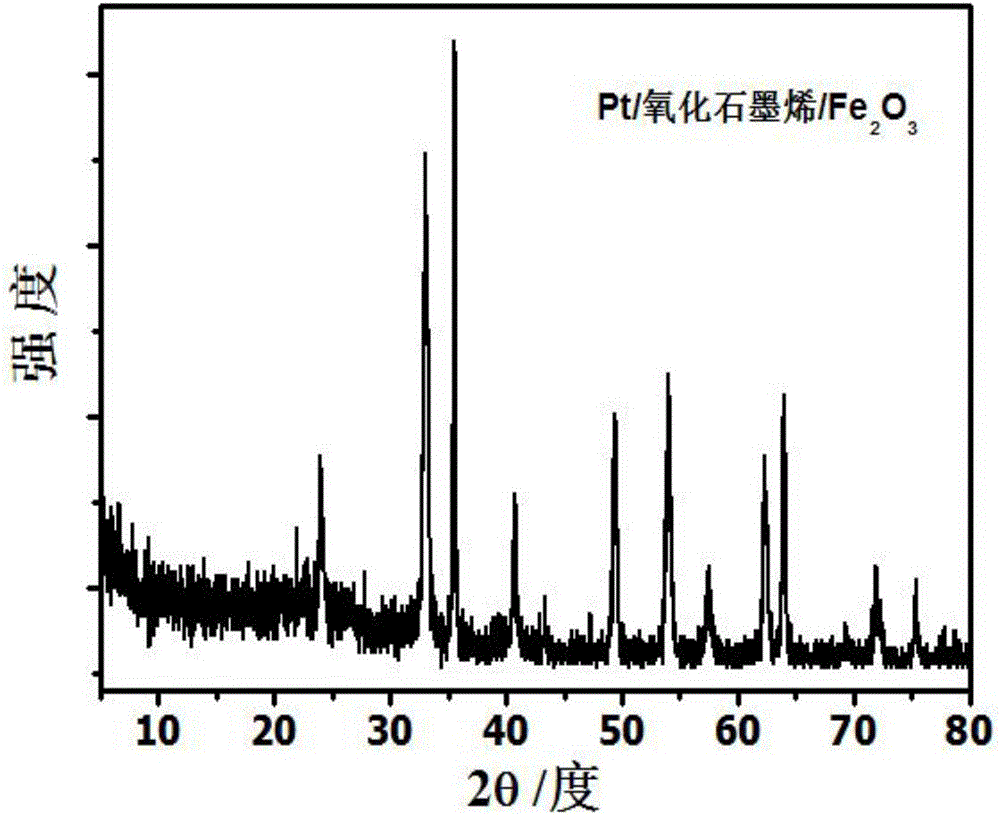

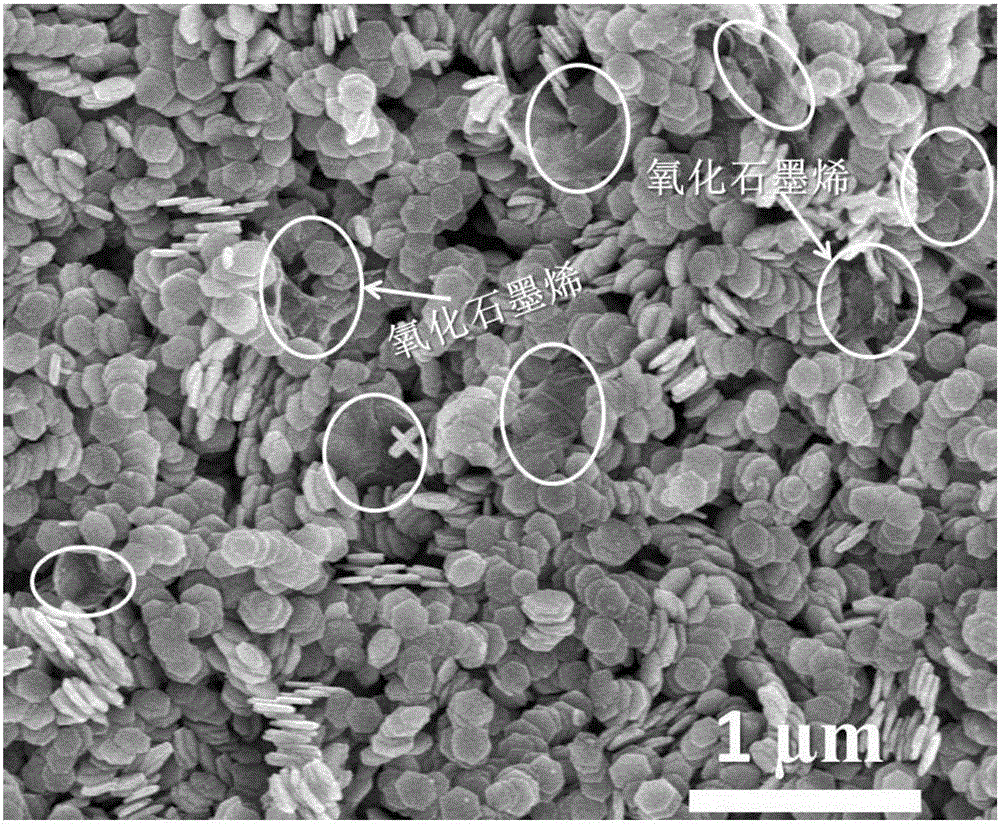

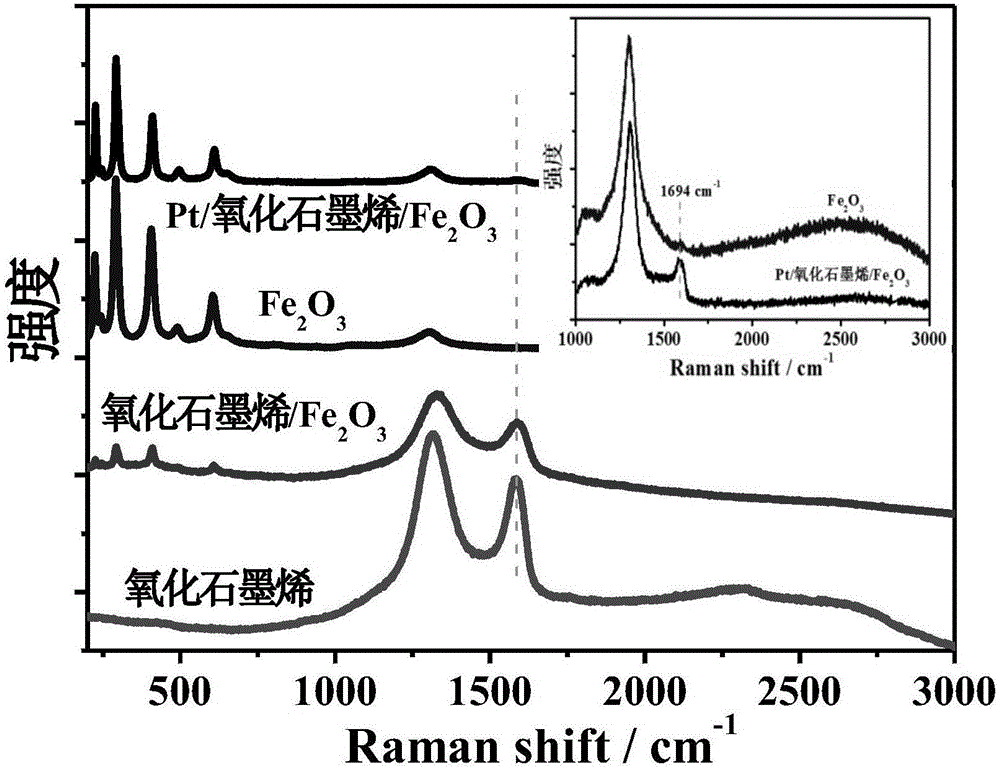

[0034] Preparation of Pt / Graphene Oxide / Fe 2 o 3 The concrete steps of composite catalyst are:

[0035] a. Add 0.05g graphene oxide to 30mL water-soluble solution (distilled water), and use ultrasonic cell pulverizer to ultrasonically stir for 0.5 hours to make it fully dispersed in water-soluble solution (distilled water);

[0036] b. Add 0.35g Fe to the system at 20°C 2 o 3 Nanosheets (see Facet-Dependent Cr(VI) Adsorption of Hematite Nanocrystals for preparation method, Environ.Sci.Technol.2016,50,1964-1972) magnetic stirring for 0.5 hours, Fe 2 o 3 The mass ratio of nanosheets to graphene oxide is 7:1;

[0037] c. Adding 0.9mL concentration in the system is 10g / L chloroplatinic acid hexahydrate solution as the Pt precursor solution, and continues to stir for 0.5 hour, wherein the quality of Pt in the chloroplatinic acid hexahydrate solution is the same as that of Pt (chloroplatinic acid hexahydrate solution contained in), graphene oxide, Fe 2 o 3 The percentage of ...

Embodiment 2

[0041] Preparation of Pt / Graphene Oxide / Fe 2 o 3 The concrete steps of composite catalyst are:

[0042] a. Add 0.05g graphene oxide to 30mL water-soluble solution (distilled water), and use ultrasonic cell pulverizer to ultrasonically stir for 0.5 hours to make it fully dispersed in water-soluble solution (distilled water);

[0043] b. Add 0.35g Fe to the system at 20°C 2 o 3 Nanoparticles (commercially available) magnetically stirred for 0.3 h, Fe 2 o 3 The mass ratio of nanoparticles to graphene oxide is 7:1;

[0044] c. Adding 0.9mL concentration in the system is 10g / L chloroplatinic acid hexahydrate solution as the Pt precursor solution, and continues to stir for 0.3 hours, wherein the quality of Pt in the chloroplatinic acid hexahydrate solution is the same as that of Pt (chloroplatinic acid hexahydrate solution contained in), graphene oxide, Fe 2 o 3 The percentage of mass sum of nanomaterials is 0.84%;

[0045] d. Add 5mL of reducing solution to the system to r...

Embodiment 3

[0048] Preparation of Pt / Graphene Oxide / Fe 2 o 3 The concrete steps of composite catalyst are:

[0049] a. Add 0.05g graphene oxide in 50mL water-soluble solution (20% ethanol water solution by mass fraction), and use ultrasonic cell pulverizer to ultrasonically stir for 0.5 hours to make it fully dispersed in water-soluble solution (20% ethanol water solution by mass fraction) )middle;

[0050] b. Add 0.4g Fe to the system at 40°C 2 o 3 Nanosheets (see Facet-Dependent Cr(VI) Adsorption of Hematite Nanocrystals for preparation method, Environ.Sci.Technol.2016,50,1964-1972) magnetic stirring for 0.2 hours, Fe 2 o 3 The mass ratio of nanosheets to graphene oxide is 8:1;

[0051] c. Adding 0.9mL concentration of 8g / L chloroplatinic acid hexahydrate solution in the system as the Pt precursor solution, continued to stir for 0.4 hours, wherein the quality of Pt in the chloroplatinic acid hexahydrate solution was the same as that of Pt (chloroplatinic acid hexahydrate solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com