Method for using biogas slurry to prepare liquid manure containing humic acid

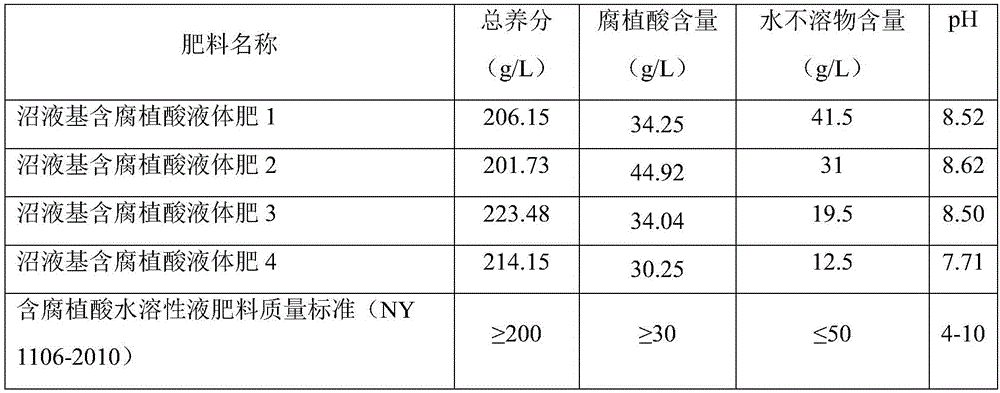

A technology of humic acid and liquid fertilizer, which is applied in the field of preparation of humic acid-containing liquid fertilizer, can solve the problems of not meeting product quality standards, low nitrogen, phosphorus and potassium nutrient content, and high insoluble content, and achieve high output and high production process Simple process and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

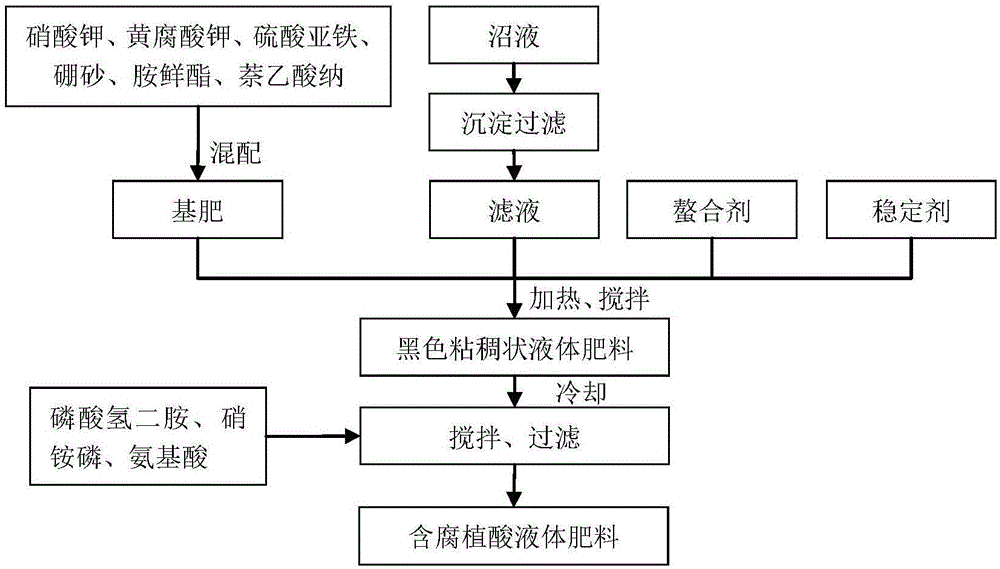

Method used

Image

Examples

Embodiment 1

[0050] Step 1: Mix potassium nitrate, potassium fulvic acid, ferrous sulfate, borax, diethyl hexanoate, and sodium naphthalene acetate in a mass ratio of 60.32:33.19:3.02:3.02:0.3:0.16 to obtain humic acid and a large number of elements base fertilizer;

[0051] Step 2: Mix the base fertilizer prepared in step 1 with biogas slurry, chelating agent, and stabilizer in a mass ratio of 109.62:346.15:10:1 to obtain viscous liquid fertilizer;

[0052] Step 3: Continuously heating and stirring the viscous liquid fertilizer prepared in step 2 at 60° C. for 2 hours to obtain a black viscous liquid fertilizer;

[0053] Step 4: Cool the black viscous liquid fertilizer prepared in step 3 to normal temperature, mix the black viscous liquid fertilizer with diammonium hydrogen phosphate, ammonium nitrate, and amino acids in a mass ratio of 28.22:1:2:2, and continuously Stir and fully dissolve to obtain a brown viscous liquid fertilizer;

[0054] Step 5: Filter the brown viscous liquid fert...

Embodiment 2

[0056] Step 1: Mix potassium nitrate, potassium fulvic acid, ferrous sulfate, borax, diethyl hexanoate, and sodium naphthalene acetate in a mass ratio of 60.32:33.19:3.02:3.02:0.3:0.16 to obtain humic acid and a large number of elements base fertilizer;

[0057] Step 2: Mix the base fertilizer prepared in step 1 with biogas slurry, chelating agent, and stabilizer in a mass ratio of 109.62:346.15:12.5:1 to obtain viscous liquid fertilizer;

[0058] Step 3: Continuously heating and stirring the viscous liquid fertilizer prepared in step 2 at 60° C. for 1 hour to obtain a black viscous liquid fertilizer;

[0059] Step 4: Cool the black viscous liquid fertilizer prepared in step 3 to normal temperature, mix the black viscous liquid fertilizer with diammonium hydrogen phosphate, ammonium nitrate, and amino acids in a mass ratio of 28.4:1:2:2, and continuously Stir and fully dissolve to obtain a brown viscous liquid fertilizer;

[0060] Step 5: Filter the brown viscous liquid fert...

Embodiment 3

[0062] Step 1: Mix potassium nitrate, potassium fulvic acid, ferrous sulfate, borax, diethyl hexanoate, and sodium naphthalene acetate in a mass ratio of 60.32:33.19:3.02:3.02:0.3:0.16 to obtain humic acid and a large number of elements base fertilizer;

[0063] Step 2: Mix the base fertilizer prepared in Step 1 with biogas slurry, chelating agent, and stabilizer in a mass ratio of 109.62:346.15:15:1 to obtain viscous liquid fertilizer;

[0064] Step 3: Continuously heating and stirring the viscous liquid fertilizer prepared in step 2 at 60° C. for 1.5 hours to obtain a black viscous liquid fertilizer;

[0065] Step 4: Cool the black viscous liquid fertilizer prepared in step 3 to normal temperature, mix the black viscous liquid fertilizer with diammonium hydrogen phosphate, ammonium nitrate, and amino acids in a mass ratio of 28.28:1:2:2, and continuously Stir and fully dissolve to obtain a brown viscous liquid fertilizer;

[0066] Step 5: Filter the brown viscous liquid fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com