Method for preparing organic fertilizer

A technology for organic fertilizer and livestock and poultry manure, which is applied in the preparation of organic fertilizer, organic fertilizer and biological organic part treatment, etc., can solve problems such as environmental pollution, and achieve the effects of solving environmental pollution, high fertilizer efficiency and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

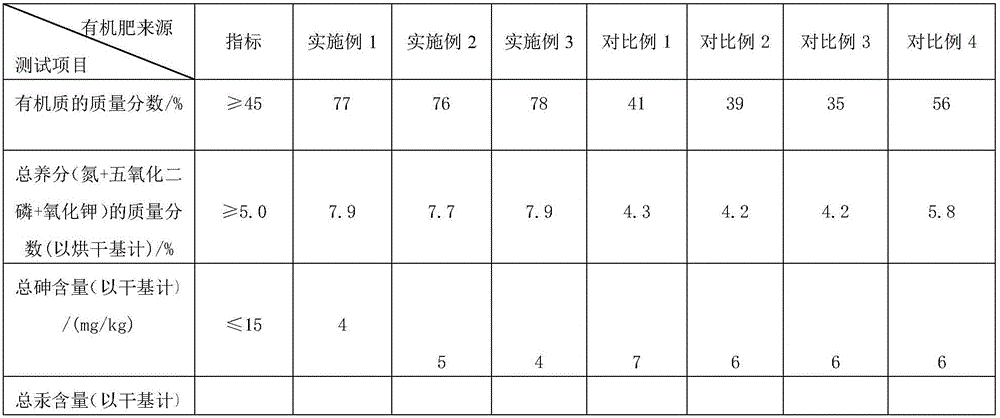

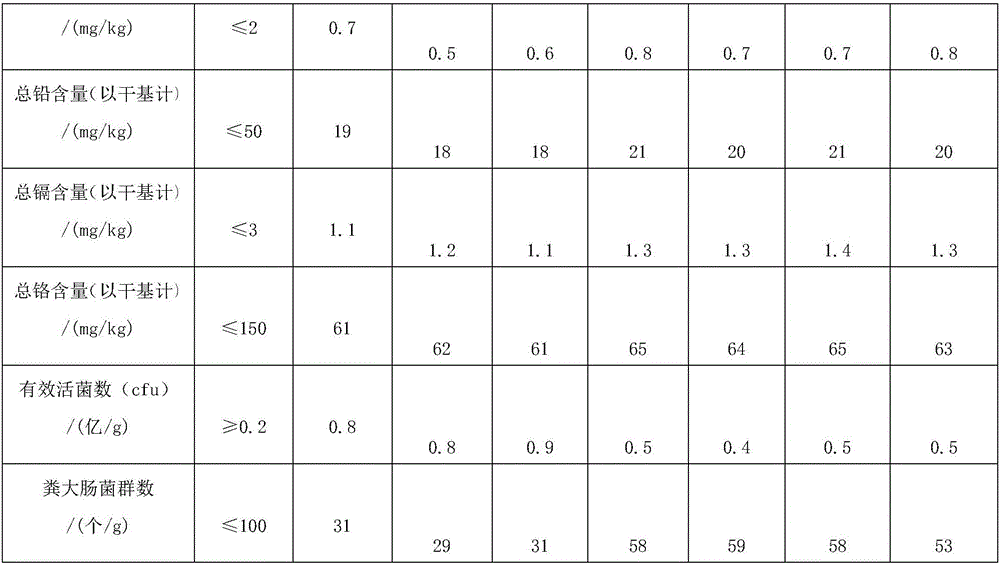

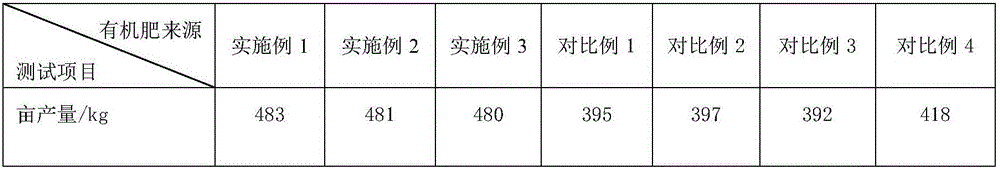

Examples

Embodiment 1

[0020] A kind of preparation method of organic fertilizer, its concrete steps are:

[0021] A. Mixing material: add 12kg peat, 12kg rice husk powder and 10kg mushroom slag to 70kg cow manure, and adjust the quality water content to 65%;

[0022] B. Fermentation: Add microbial starter to the mixture obtained in step A and stir evenly, then carry out aerobic fermentation for 15 days, and the mass ratio of mixture to microbial starter is 95:2.

[0023] In step B, the microbial starter is mixed with the following raw materials by mass: 25 parts of Streptococcus faecalis, 5 parts of Lactobacillus, 10 parts of Bacillus subtilis, 4 parts of yeast and 3 parts of cellulase; The number of viable streptococci is not less than 3×10cfu / kg.

[0024] In step B, during the fermentation process, turn over and throw once every 2 days; cover the greenhouse with shade cloth for 12 hours every 5 days; the width of the fermentation tank is 4.5 meters, and the height is 1.2 meters; Air intake is 7...

Embodiment 2

[0026] A kind of preparation method of organic fertilizer, its concrete steps are:

[0027] A. Mixing material: add 10kg peat, 15kg rice husk powder and 6kg mushroom slag to 72kg cow manure, and adjust the quality water content to 61%;

[0028] B. Fermentation: Add microbial starter to the mixture obtained in step A, stir evenly, and carry out aerobic fermentation for 20 days. The mass ratio of the mixture to the microbial starter is 90:3.

[0029] In step B, the microbial starter is mixed with the following raw materials by mass: 15 parts of Streptococcus faecalis, 10 parts of Lactobacillus, 15 parts of Bacillus subtilis, 7 parts of yeast and 5 parts of cellulase; The number of viable streptococci is not less than 3×10cfu / kg.

[0030] In step B, during the fermentation process, turn over and throw once every other day; cover the greenhouse with shade cloth for 8 hours every 4 days; the width of the fermentation tank is 4.2 meters, and the height is 0.9 meters; Air intake is...

Embodiment 3

[0032] A kind of preparation method of organic fertilizer, its concrete steps are:

[0033] A. Mixing materials: Add 11kg peat, 13kg rice husk powder and 8kg mushroom slag to 71kg cow manure, and adjust the quality water content to 63%;

[0034] B. Fermentation: Add a microbial starter to the mixture obtained in step A and stir evenly, then carry out aerobic fermentation for 17 days, and the mass ratio of the mixture to the microbial starter is 93:2.5.

[0035] In step B, the microbial starter is mixed from the following raw materials by mass: the microbial starter is mixed from the following raw materials by mass: 20 parts of Streptococcus faecalis, 8 parts of Lactobacillus, and 12 parts of Bacillus subtilis , 6 parts of yeast and 4 parts of cellulase; the number of viable Streptococcus faecalis is not less than 3×10cfu / kg.

[0036] In the step B, turn and throw once every 2 days during the fermentation process; cover the greenhouse with a shade cloth for 10 hours every 4 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com