Fuel gas/fuel oil synergist for industrial kiln stove and boiler and preparation method and application of fuel gas/fuel oil synergist

A synergist and kiln technology, applied in the petroleum industry, fuel, gas fuel, etc., can solve the problems of no energy saving and emission reduction, human injury, sealing power, etc., to save gas, reduce nitrogen emissions, and improve energy saving rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

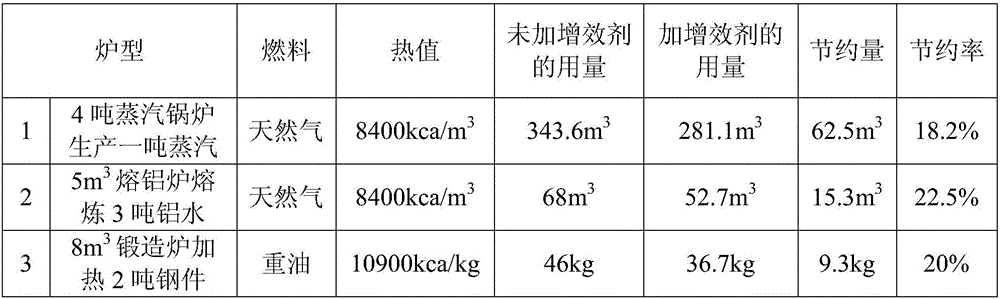

Image

Examples

Embodiment 1

[0034] The gas / fuel synergist for industrial kilns and boilers of the present invention comprises the following materials, by weight: a mixture containing transition group metallocenes and cattoxins (wherein, nickel, cerium and cattoxins The mass ratio is 3:3:4) 25%, methyl tert-butyl ether 15%, cyclohexane peroxide 15%, absolute ethanol 20%, isopropanol 5%, ethylene glycol monobutyl ether 10% , petroleum ether 10%.

[0035] The preparation method of described industrial kiln and boiler gas / fuel oil synergist, comprises the steps:

[0036] According to the above ratio, the above materials are mixed at room temperature with methyl tert-butyl ether - a mixture containing transition group metallocenes and cattosine, and stirred evenly to obtain a mixture; then cyclohexane peroxide - absolute ethanol ——Isopropanol——Ethylene glycol monobutyl ether is added to the above mixture in turn, and stirred evenly to obtain a light yellow solution, which is left to stand for 2 hours to filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com