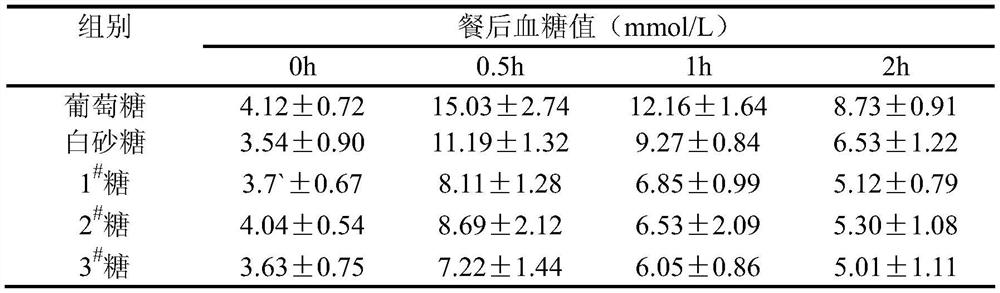

A preparation method of functional sucrose with hypoglycemic function

A functional and sucrose technology, which is applied in the preparation of functional sucrose and the field of sucrose preparation, can solve the problems of poor stability and low dose-effectiveness of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Select brown sugar with a color value of 4500IU in the beet sugar factory as raw material, dissolve the brown sugar with hot water into 60Bx syrup, filter to remove sediment and suspended matter, and obtain clear syrup;

[0039] 2. Take 500g of dry bagasse and crush it to a particle size of 120 mesh; add 50% (volume concentration) ethanol solution of 3 times the volume of bagasse, soak for 18 hours, and filter coarsely; the filtrate is concentrated to remove 70% of the volume of ethanol solution after 0.2 μm microfiltration , to get the concentrated solution; add the acetic acid of 5% volume of the concentrated solution, and separate the upper chromatographic column of the mixed solution, the column packing is AB-8 resin, first use the acetic acid of 0.1 (v / v) of 1AB-8 volume, and then use 60 % (v / v) ethanol aqueous solution to elute the chromatographic column, collect the eluent, concentrate in vacuum to 50Bx, and determine that the extract contains 0.23% alfalfa...

Embodiment 2

[0045] 1. Select sugarcane raw sugar with a color value of 1500IU, dissolve the raw sugar with dilute sugar juice to form a 62Bx syrup, and filter to remove sediment and suspended matter to obtain clear syrup;

[0046] 2, 300g sugarcane is slightly crushed through 80 mesh sieves; add 4 times the volume concentration of cane sugar to be 70% ethanol solution, soak for 13 hours, coarse filter, and the filtrate is concentrated to remove 80% volume of ethanol solution after 0.22 μm microfiltration, to obtain Concentrate; add 6% volume of acetic acid in the concentrate, and separate the mixed solution on a chromatographic column. The column filler is D730 resin. Elute the chromatographic column with ethanol aqueous solution, collect the eluent, concentrate in vacuum to 35Bx, and determine that the extract contains 0.30% alfalfalin, 0.29% diglycoside, 0.25% apigenin, 0.20% luteolin, and 0.35% chlorogenic acid , 0.75% of ferulic acid, 0.85% of caffeic acid, 0.13% of epicatechin, 0....

Embodiment 3

[0054] 1. Select sugarcane clear syrup with a solid content of 70Bx for use;

[0055] 2. Slightly pulverize 200g of bagasse and 100g of sugarcane to a particle size of 100 mesh; add 4 times the volume of 60% ethanol solution to soak for 10 hours, coarsely filter, and concentrate the filtrate to remove 75% of the volume of ethanol solution after 1.0 μm microfiltration; add 7% of the concentrated solution volume of acetic acid, separate the mixed solution on a chromatographic column, the column filler is D101 macroporous adsorption resin, first use 3D101 volume of 0.5v / v acetic acid, and then use 70% v / v ethanol aqueous solution to elute the chromatographic column, The eluate was collected, concentrated in vacuum to 42Bx, and the extract contained 0.29% alfalfalin, 0.25% apigenin, 0.32% diglycoside, 0.32% luteolin, 0.37% chlorogenic acid, 0.94% ferulic acid, coffee 0.70% acid, 0.27% protocatechin, 0.15% tricoflavone, 0.21% pliol, 3.82% total active ingredients such as alfalf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com