Novel aqueous polyurethane-acrylate composite impregnating resin and preparation method thereof

A polyurethane acrylic, impregnating resin technology, applied in the field of decorative paper, can solve the problem of inability to eliminate formaldehyde, and achieve the effect of flexible texture, good homochromaticity and texture, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

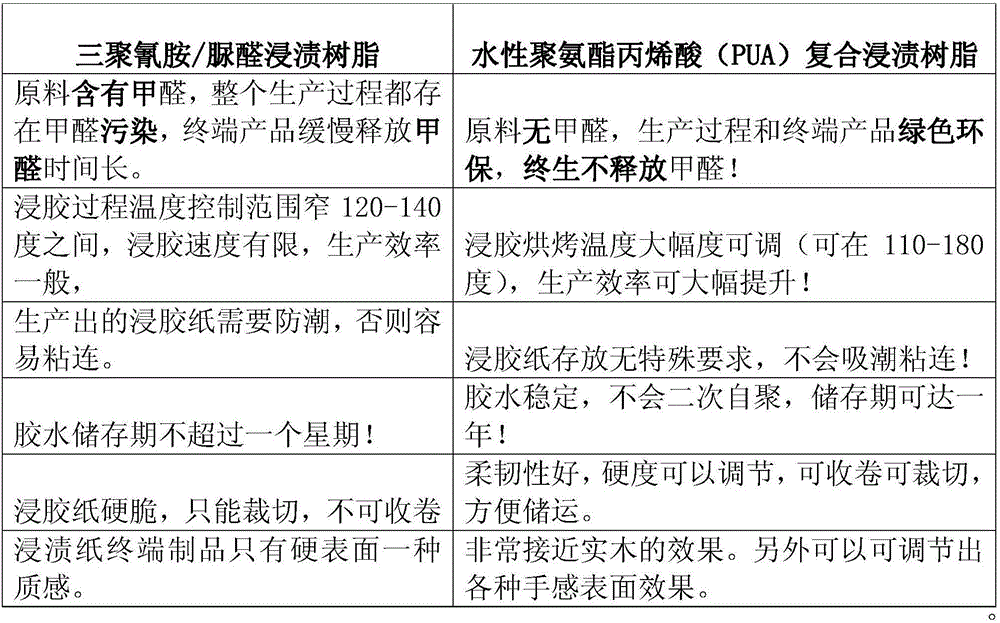

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Novel water-based polyurethane acrylic composite impregnating resin, comprising the following components and corresponding parts by weight:

[0023] Acrylate monomer 55, 1,4-butanediol (BDO) 1, dimethylolpropionic acid DMPA 5, trimethylolpropane 2, diethylenetriamine 1.5;

[0024] N, N-dihydroxy (diisopropyl) aniline (HPA) 1, diisocyanate (IPDI) 20, polytetrahydrofuran ether glycol 15, oxidized polypropylene glycol (PPG) 20, dimethylethanolamine 6, acetone 30 , Dibutyltin dilaurate (DY-12) 0.04;

[0025] Adipic dihydrazide (ADH) 5, diacetone acrylamide 15, sodium formaldehyde sulfoxylate 0.1, potassium persulfate 1.3, sodium bicarbonate 1, tert-butyl hydroperoxide 0.5, phenylpropisothiazolinone 0.5, de Ionized water 350.

[0026] The acrylate monomer is composed of butyl acrylate, dibutyl maleate, hydroxyethyl acrylate, isooctyl methacrylate, methacrylic acid and styrene in the ratio of 2:10:2:15:2:40 .

[0027] The preparation method is as follows:

[0028] (1) Fi...

Embodiment 2

[0033] Novel water-based polyurethane acrylic composite impregnating resin, comprising the following components and corresponding parts by weight:

[0034] Acrylate monomer 65, 1,4-butanediol (BDO) 2, dimethylolpropionic acid DMPA 2, trimethylolpropane 5, diethylenetriamine 0.5;

[0035] N, N-dihydroxy (diisopropyl) aniline (HPA) 3, diisocyanate (IPDI) 10, polytetrahydrofuran ether glycol 10, oxidized polypropylene glycol (PPG) 30, dimethylethanolamine 2, acetone 50 , Dibutyltin dilaurate (DY-12) 0.02;

[0036] Adipic dihydrazide (ADH) 7, diacetone acrylamide 10, sodium formaldehyde sulfoxylate 0.5, potassium persulfate 1, sodium bicarbonate 1.5, tert-butyl hydroperoxide 0.1, phenylisothiazolinone-1, Deionized water 360.

[0037] The acrylate monomer is composed of butyl acrylate, dibutyl maleate, hydroxyethyl acrylate, isooctyl methacrylate, methacrylic acid and styrene in the ratio of 3:8:4:13:3:35 .

[0038] The preparation method is as follows:

[0039] (1) First reac...

Embodiment 3

[0044] Novel water-based polyurethane acrylic composite impregnating resin, comprising the following components and corresponding parts by weight:

[0045] Acrylate monomer 60, 1,4-butanediol (BDO) 1.5, dimethylolpropionic acid DMPA 3, trimethylolpropane 4, diethylenetriamine 1;

[0046]N, N-dihydroxy (diisopropyl) aniline (HPA) 2, diisocyanate (IPDI) 15, polytetrahydrofuran ether glycol 13, oxidized polypropylene glycol (PPG) 25, dimethylethanolamine 4, acetone 40 , Dibutyltin dilaurate (DY-12) 0.03;

[0047] Adipic dihydrazide (ADH) 6, diacetone acrylamide 13, sodium formaldehyde sulfoxylate 0.3, potassium persulfate 1.2, sodium bicarbonate 1.3, tert-butyl hydroperoxide 0.3, phenylpropisothiazolinone 0.8, de Ionized water 350.

[0048] The acrylate monomer is composed of butyl acrylate, dibutyl maleate, hydroxyethyl acrylate, isooctyl methacrylate, methacrylic acid and styrene in the ratio of 4:5:5:10:5:30 .

[0049] The preparation method is as follows:

[0050] (1) Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com