Polyethylene grafted carbon nanomaterial, and preparation method thereof

A technology of polyethylene grafting and carbon nanomaterials, which is applied in the field of nanomaterials and can solve problems such as difficulties in olefin polymerization and polyolefin graft modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

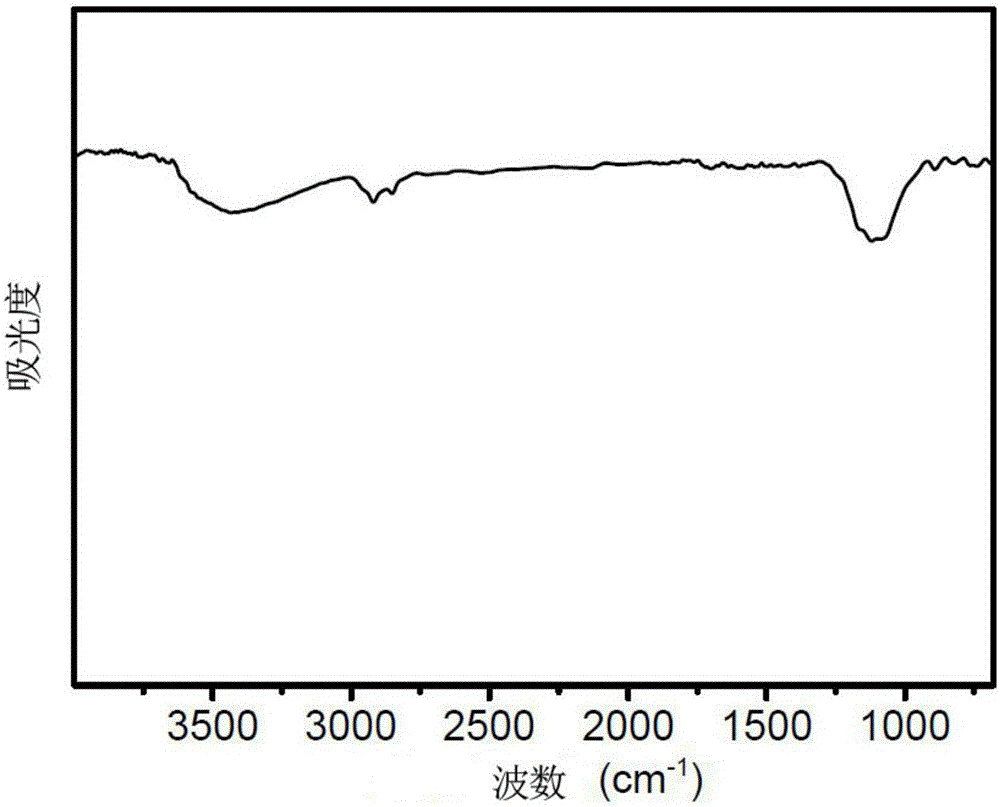

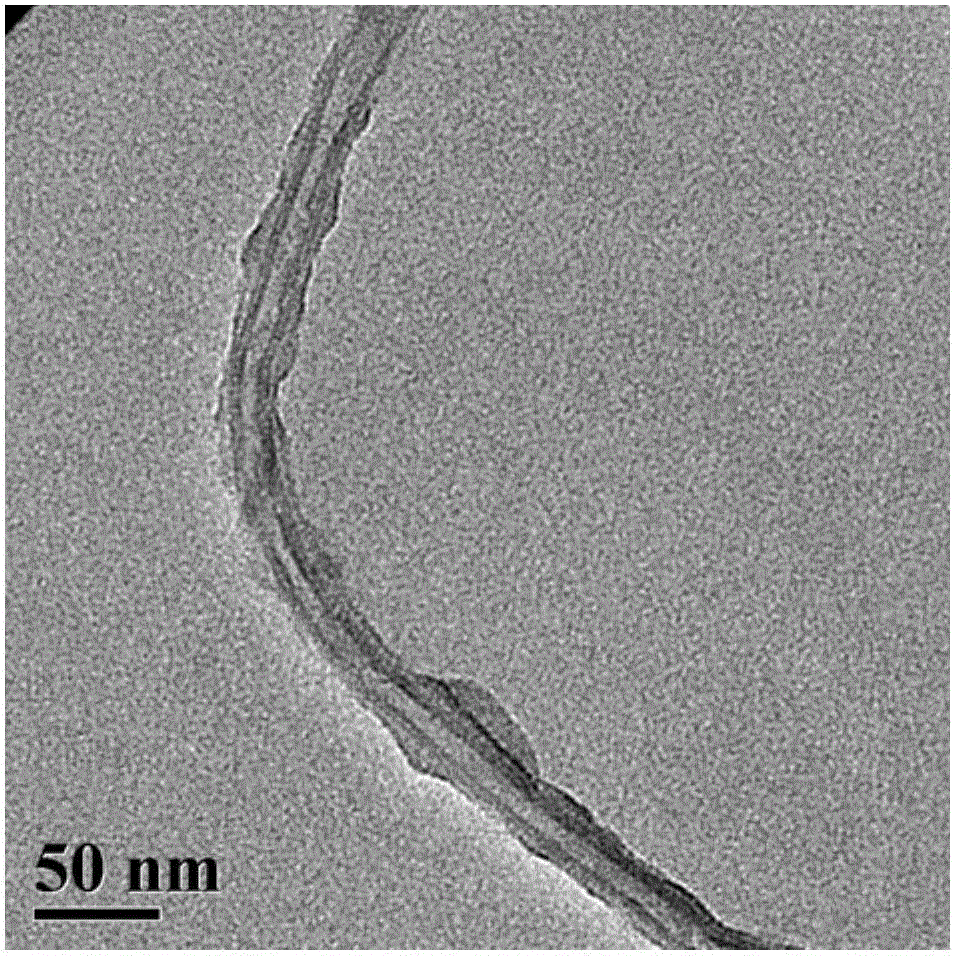

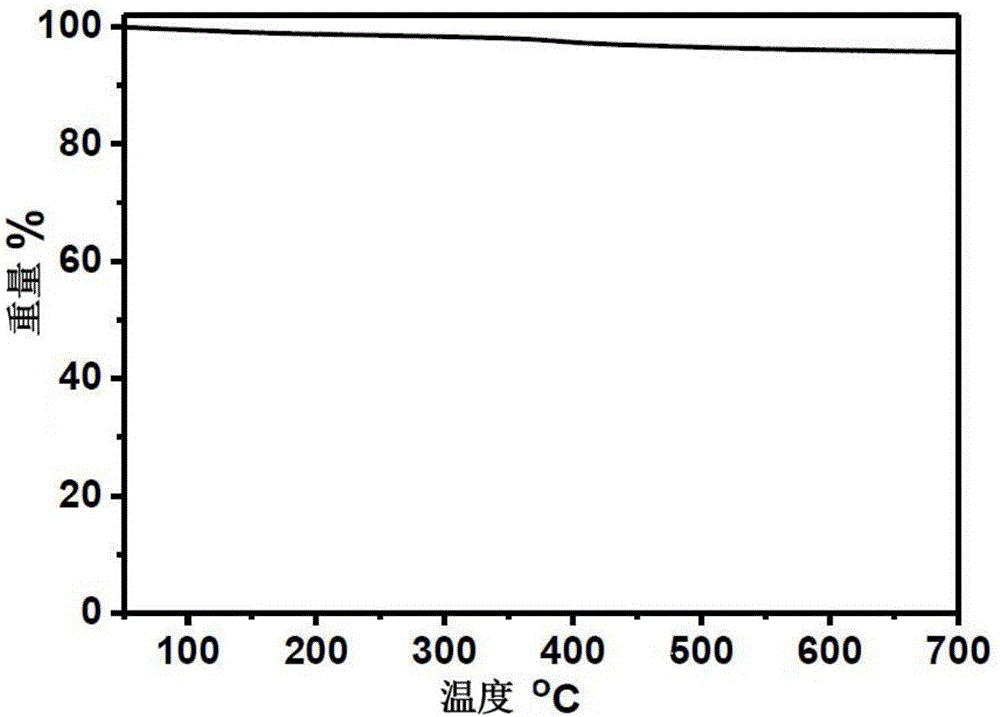

[0094] This embodiment provides a preparation method of polyethylene-grafted carbon nanomaterials (polyethylene-grafted carbon nanotubes), the steps of which are as follows:

[0095] Take 0.5 g of carbon nanotubes and disperse them ultrasonically in 150 mL of tetrahydrofuran for 1 hour, then bubble nitrogen for 15 minutes. 0.5 g of phthaloyl peroxide and 2.5 mL of (3-mercaptopropyl)trimethoxysilane were added. Under the protection of nitrogen, react in an oil bath at 60°C for 12 hours. After the reaction, the solid was obtained by filtration; washed three times with tetrahydrofuran, and dried in vacuum at 40° C. for 12 hours to obtain trimethoxysilane-modified carbon nanotubes (structure shown in formula A-1).

[0096] Take 0.5 g of the trimethoxysilane-modified carbon nanotubes prepared above and first disperse them in 150 mL of toluene. After ultrasonic dispersion for 1 hour, add 3 g of trimethylsiloxane-capped polyethylene (as shown in formula A-0, where PE is a polyethyl...

Embodiment 2

[0100] This embodiment provides a preparation method of polyethylene-grafted carbon nanomaterials (polyethylene-grafted carbon nanotubes), the steps of which are as follows:

[0101] Take 2 g of carboxylated carbon nanotubes and ultrasonically disperse them in 600 mL of chlorobenzene system for 0.5 hours. 0.25 g of N-hydroxyphthalimide and 10 mL of (2-isocyanatoethyl)tripropoxysilane were added. Under the protection of nitrogen, react in an oil bath at 60°C for 12 hours. After the reaction, the solid was obtained by filtration; washed three times with alcohol, and dried in vacuum at 40° C. for 12 hours to obtain a carbon nanotube modified with tripropropoxysilane (expressed in formula B-1).

[0102] Take 0.5g of the above-mentioned tripropropoxysilane-modified carbon nanotubes and first disperse them in 500mL of chlorobenzene. After ultrasonic dispersion for 0.5 hours, add 7g of triethylsiloxane-capped polyethylene (as shown in formula B-0), Put it in a 130°C oil bath to ful...

Embodiment 3

[0106] This embodiment provides a preparation method of polyethylene-grafted carbon nanomaterials (polyethylene-grafted carbon nanotubes), the steps of which are as follows:

[0107] Take 1 g of hydroxylated carbon nanotubes and ultrasonically disperse them in 500 mL of dimethyl sulfoxide for 1 hour. Add 0.1 g stannous octoate, 0.1 g ditin dilaurate and 10 mL (5-aminopentyl) triethoxysilane. Under the protection of nitrogen, react in an oil bath at 60°C for 12 hours. After the reaction, the solid was obtained by filtration; washed three times with alcohol, and dried in vacuum at 40° C. for 12 hours to obtain triethoxysilane-modified carbon nanotubes (expressed in formula C-1).

[0108] Take 3g of the triethoxysilane-modified carbon nanotubes prepared above and first disperse them in 1000mL of benzene. After ultrasonic dispersion for 1 hour, add 20g of tripropylsiloxane-capped polyethylene (as shown in formula C-0) , placed in a 140°C oil bath to fully dissolve. 0.2 g of 1,8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com