Anti-pollution, anti-corrosion and anti-bacterial stainless steel plate and preparation method thereof

A technology of antibacterial stainless steel and stainless steel plate, applied in the direction of antifouling/underwater coating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of complex production process, high production cost, single performance, etc., and achieve high safety, Enhanced corrosion resistance and mild components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

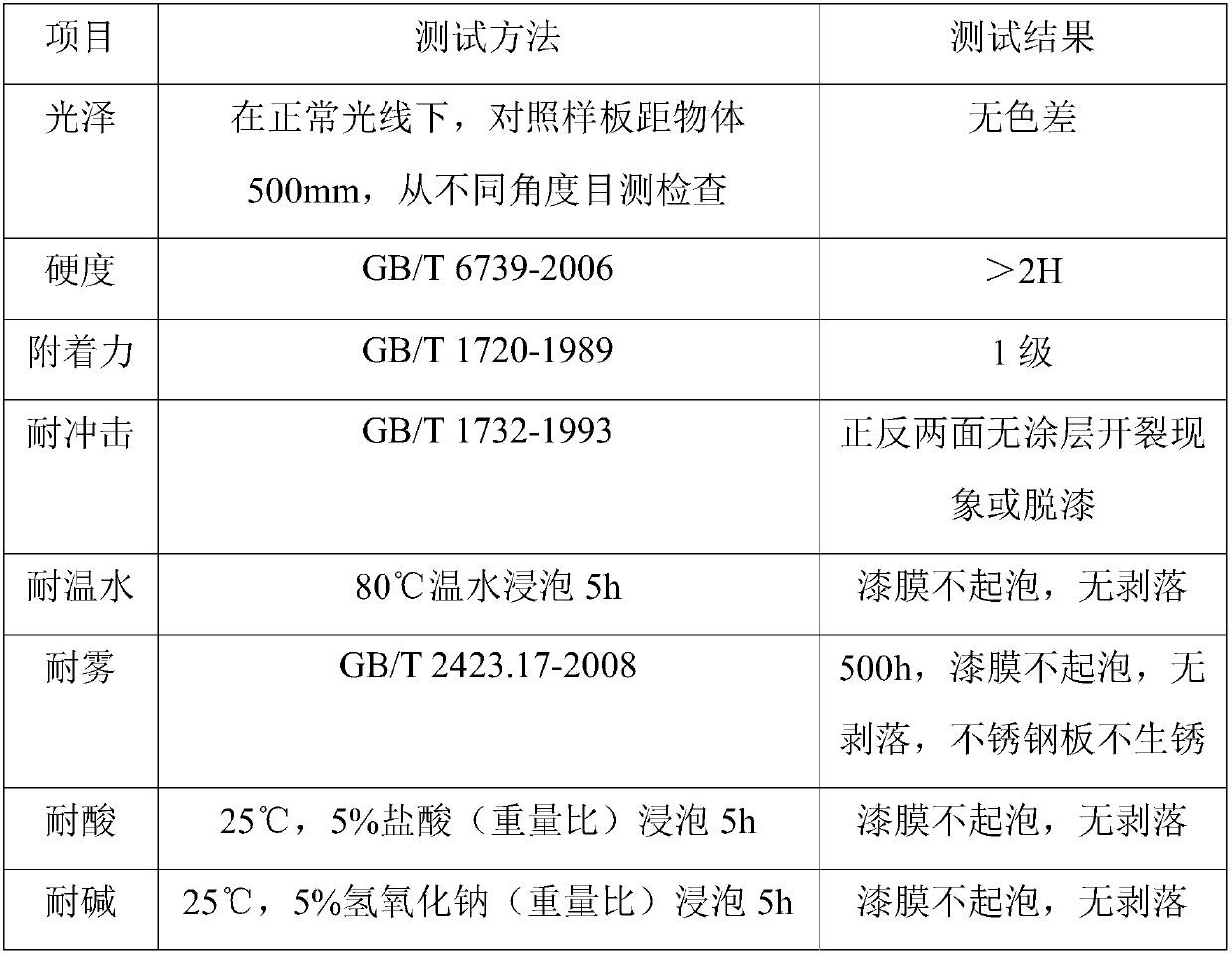

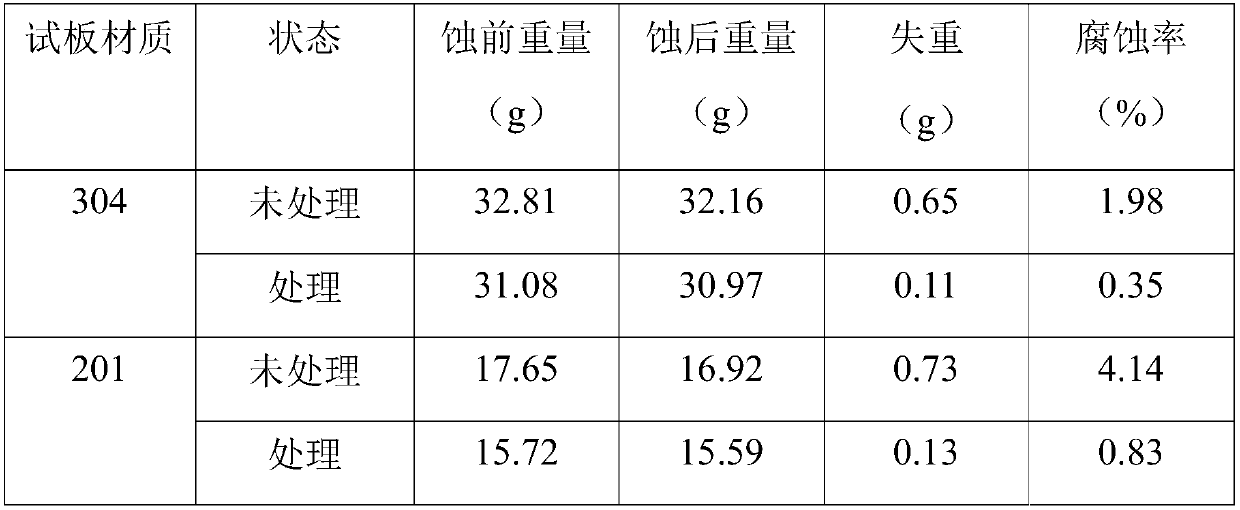

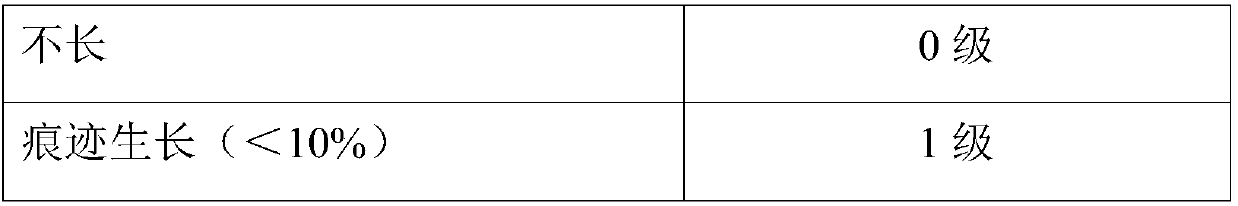

Examples

Embodiment 1

[0038] An anti-pollution, corrosion-resistant and antibacterial stainless steel plate, the preparation method of which comprises the following steps:

[0039] (1) Mechanical polishing: polish the surface of the stainless steel plate with sandpaper;

[0040] (2) Alkaline cleaning: put the mechanically polished stainless steel plate into Na2 CO 3 Soak in the mixture of NaOH and NaOH for 15min, take it out, and dry it in the air; where Na 2 CO 3 The concentrations of NaOH and NaOH are both 5g / mL;

[0041] (3) pickling: put the stainless steel plate after alkali washing into hydrochloric acid and soak for 10 minutes, take it out, and dry it;

[0042] (4) Passivation: Put the pickled stainless steel plate into the passivation solution, and passivate it for 5 minutes at an anode voltage of 6 volts; the passivation solution consists of 2g / mL citric acid, 200mL / L glacial acetic acid, 2g / mL NaCl, 2mL / L H 2 o 2 and 1g / mL agar powder;

[0043] (5) Oxidation: Place the passivated ...

Embodiment 2

[0060] An anti-pollution, corrosion-resistant and antibacterial stainless steel plate, the preparation method of which comprises the following steps:

[0061] (1) Mechanical polishing: polish the surface of the stainless steel plate with sandpaper;

[0062] (2) Alkaline cleaning: put the mechanically polished stainless steel plate into Na 2 CO 3 Soak in the mixture of NaOH and NaOH for 20min, take it out, and dry it in the air; where Na 2 CO 3 The concentrations of NaOH and NaOH are both 3g / mL;

[0063] (3) pickling: put the stainless steel plate after alkali washing into hydrochloric acid and soak for 15 minutes, take it out, and dry it;

[0064] (4) Passivation: Put the pickled stainless steel plate into the passivation solution, and passivate it for 8 minutes at an anode voltage of 4 volts; the passivation solution consists of 5g / mL citric acid, 300mL / L glacial acetic acid, 5g / mL sodium chloride, 5mL / L H 2 o 2 and 2g / mL agar powder;

[0065] (5) Oxidation: place th...

Embodiment 3

[0082] An anti-pollution, corrosion-resistant and antibacterial stainless steel plate, the preparation method of which comprises the following steps:

[0083] (1) Mechanical polishing: polish the surface of the stainless steel plate with sandpaper;

[0084] (2) Alkaline cleaning: put the mechanically polished stainless steel plate into Na 2 CO 3 Soak in the mixture of NaOH and NaOH for 20min, take it out, and dry it in the air; where Na 2 CO 3 The concentration of NaOH is 5g / mL, and the concentration of NaOH is 3g / mL;

[0085](3) pickling: put the stainless steel plate after alkali washing into hydrochloric acid and soak for 15 minutes, take it out, and dry it;

[0086] (4) Passivation: Put the pickled stainless steel plate into the passivation solution, and passivate it for 6 minutes under the condition of the anode voltage of 5 volts; the passivation solution consists of 4g / mL citric acid, 300mL / L glacial acetic acid, 3g / mL NaCl, 3mL / L H 2 o 2 and 1.5g / mL agar powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com