Precure sulfur-tolerant shift conversion catalyst and preparation method thereof

A sulfur-resistant conversion and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unseen large-scale industrial applications, affecting the normal start-up process, and endangering the health of operators, etc. problems, achieve good economic benefits and application prospects, reduce the start-up time of enterprises, and facilitate transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

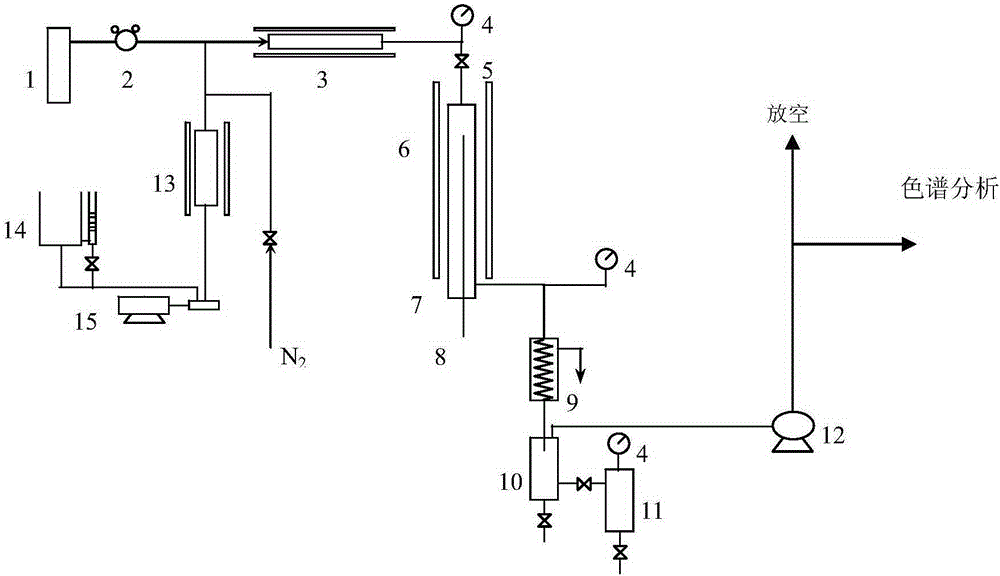

Image

Examples

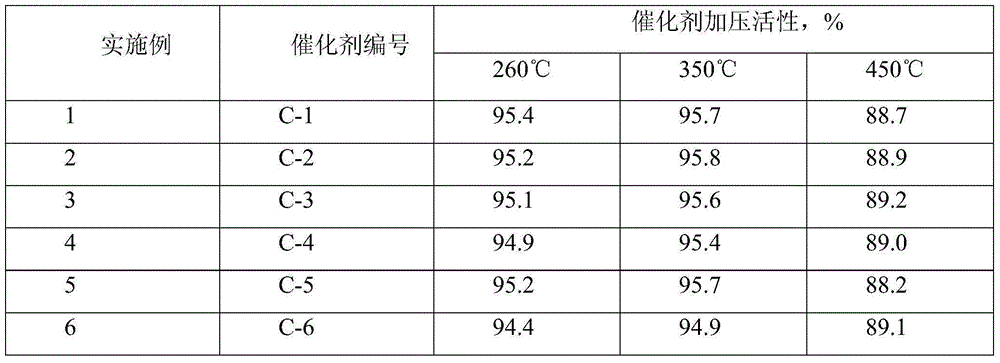

Embodiment 1

[0044] First, dissolve 16.5g of ammonium molybdate with 40mL of concentrated ammonia water, then add 6g of ammonium sulfide solution, and stir evenly to obtain molybdenum-containing solution A; dissolve 16.0g of cobalt nitrate with 35mL of deionized water; Add 5 g of acetamide into the above solution, stir and dissolve to obtain a cobalt-containing mixed solution B.

[0045] Weigh 105g of pseudo-boehmite, 10g of magnesia and 6g of cinnamon powder, mix evenly, add solution A, knead evenly; then add solution B, knead evenly, and then extrude into strips, and place the molded catalyst at room temperature for 24 hours to air naturally Dry and first roasting is carried out in a nitrogen atmosphere containing 10% hydrogen, the roasting temperature is 300°C, and the roasting time is 6h. The second calcination was carried out in a pure nitrogen atmosphere at a temperature of 550° C. and a calcination time of 3 hours. Cool the roasted sulfur-resistant shift catalyst to room temperatur...

Embodiment 2

[0047] First, dissolve 11.2g of ammonium molybdate with 45mL of concentrated ammonia water, then add 4.2g of ammonium sulfide solution, and stir evenly to obtain molybdenum-containing solution A; dissolve 12.8g of cobalt nitrate with 30mL of deionized water; 2g and 3.5g of thioacetamide were added to the above solution, stirred and dissolved to obtain a cobalt-containing mixed solution B.

[0048] Weigh 71g of alumina, 55g of magnesium oxalate and 8g of starch and mix evenly, add solution A, knead evenly; then add solution B, knead evenly, and then extrude into strips, and place the molded catalyst at room temperature for 28h to dry naturally. The secondary calcination was carried out in a nitrogen atmosphere containing 1% hydrogen, the calcination temperature was 280°C, and the calcination time was 8h. The second calcination was carried out in a pure nitrogen atmosphere at a temperature of 600° C. and a calcination time of 1 h. The calcined sulfur-tolerant shift catalyst was...

Embodiment 3

[0050] First, dissolve 9.0 g of ammonium molybdate with 40 mL of ammonia water, then add 3.5 g of ammonium sulfide solution, and stir evenly to obtain molybdenum-containing solution A; dissolve 9.6 g of cobalt nitrate with 40 mL of deionized water; then dissolve 1 g of citric acid and 2 g of sucrose and 2.5 g of thioacetamide were added to the above solution, stirred and dissolved to obtain a cobalt-containing mixed solution B.

[0051] Weigh 138g of aluminum glue, 20g of magnesia and 4g of scallop powder and mix evenly, add solution A, knead evenly; then add solution B, knead evenly, and then extrude into strips, and place the molded catalyst at room temperature for 48h to dry naturally. The primary calcination is carried out in a nitrogen atmosphere containing 15% hydrogen, the calcination temperature is 320°C, and the calcination time is 2h. The second calcination was carried out in a pure nitrogen atmosphere at a temperature of 500° C. and a calcination time of 4 hours. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com