Strontium-containing bone cement and preparation method

A technology of bone cement and cement, which is applied in the direction of medical formula, medical science, prosthesis, etc., can solve the problems of not lowering the curing temperature of bone cement, not lowering or slowing down the exothermic reaction of bone cement, etc., so as to facilitate heat loss and reduce Damage to the human body, the effect of reducing the accumulation of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Take by weighing corresponding strontium ranelate (1%), polyacrylate (59%) containing benzoyl peroxide, barium sulfate (10%), calcium sulfate (15%) according to the mass percentage of powder %) and calcium phosphate (15%), uniformly mixed to obtain bone cement powder, a total of 20g;

[0033] (2) Measure 15 g of hydroquinone-containing methacrylate (95%) and N,N dimethyl-p-toluidine (5%) to obtain a bone cement liquid;

[0034] (3) According to the powder-liquid mass ratio of 1.33:1, the powder was added into the liquid and mixed evenly, and solidified to obtain the strontium-containing bone cement. The bone cement injection time was 12 minutes.

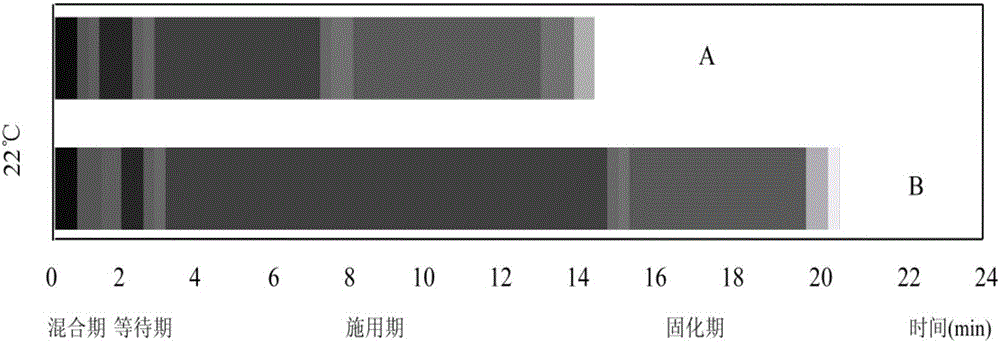

[0035] Operability see attached figure 1 As shown in -A, the bone cement can be used for injection in 3 minutes, with an injection time of 12 minutes, and finally solidifies in 20 minutes. figure 1 -B compared with strontium-free bone cement, adding strontium ranelate, the injection time of bone cement was extended from ...

Embodiment 2

[0039] (1) Take by weighing corresponding strontium ranelate (0.01%), polyacrylate (49%) containing benzoyl peroxide, barium sulfate (30%), calcium sulfate (10.99%) according to the mass percentage of powder %) and calcium phosphate (10%), uniformly mixed to obtain bone cement powder, a total of 20g;

[0040] (2) Weigh strontium ranelate (1%) and add it to hydroquinone-containing methacrylate (94%) and N,N dimethyl-p-toluidine (5%), mix well to obtain bone cement Liquid, a total of 10g;

[0041] (3) According to the powder-liquid mass ratio of 2:1, the powder was added to the liquid and mixed evenly, and solidified to obtain the strontium-containing bone cement. The bone cement injection time was 9 minutes.

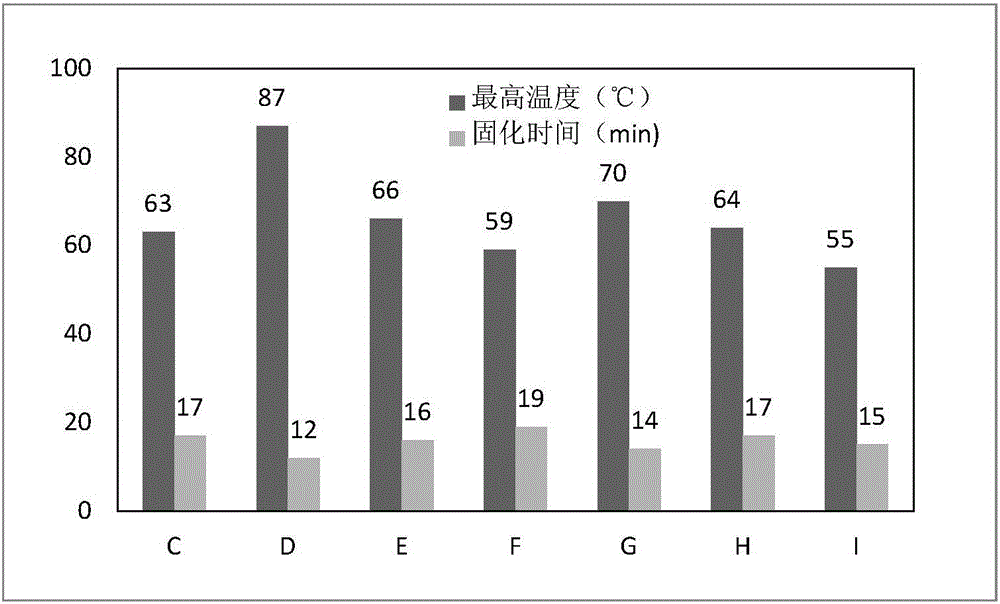

[0042] Determine the curing temperature of bone cement according to the standard requirements and methods, by figure 2 -E shows that the maximum temperature of the bone cement is 66°C, and the curing time is 16 minutes.

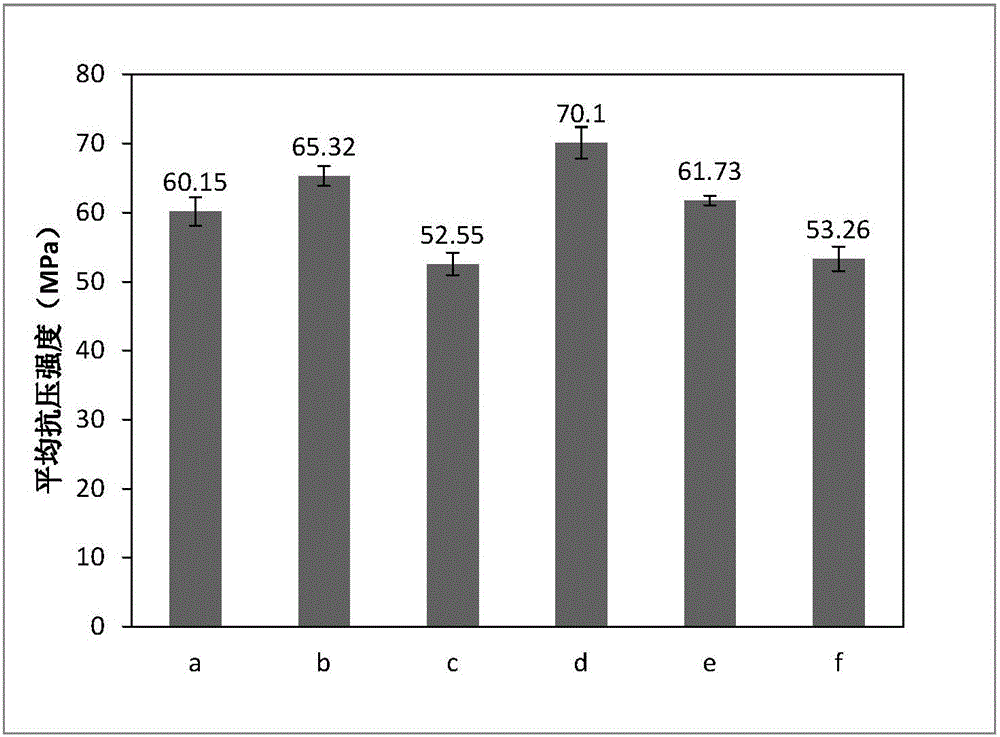

[0043] Measure the compressive strength of bon...

Embodiment 3

[0045] (1) Take by weighing corresponding strontium ranelate (0.2%), polyacrylate (49.8%) containing benzoyl peroxide, barium sulfate (10%), calcium sulfate (30%) according to the mass percentage of powder %) and calcium phosphate (10%), uniformly mixed to obtain bone cement powder, a total of 20g;

[0046] (2) Weigh strontium ranelate (0.3%) and add it to hydroquinone-containing methacrylate (96.9%) and N,N dimethyl-p-toluidine (2.8%), and mix well to obtain bone cement Liquid, 20g in total;

[0047] (3) According to the powder-liquid mass ratio of 1:1, the powder was added into the liquid and mixed evenly, and solidified to obtain the strontium-containing bone cement. The bone cement injection time was 12 minutes.

[0048] Determine the curing temperature of bone cement according to the standard requirements and methods, by figure 2 -F shows that the maximum temperature of the bone cement is 59°C and the curing time is 19 minutes.

[0049]Measure the compressive strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution range | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com