Preparation method of dithiocarbamate functionalized lignin microspheres

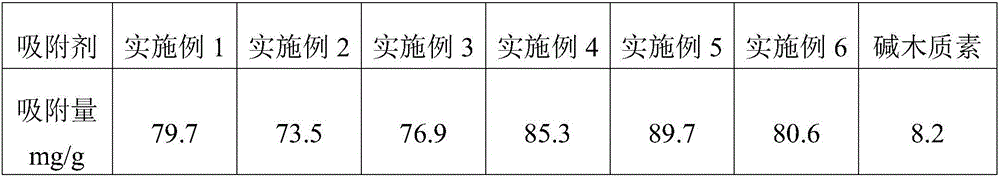

A dithiocarbamate and lignin technology, which is applied in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problem of uneven particle size of lignin microspheres, lack of effective functional groups, shape It can solve the problems of poor controllability of appearance and other problems, and achieve the effect of good industrial application prospect, remarkable adsorption performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of dithiocarbamate functionalized lignin microspheres, the operation steps are as follows:

[0029] (1) Preparation of dispersed phase solution: Alkali lignin is dissolved in water to prepare an aqueous alkali lignin solution with a mass percentage of 5%, then add crosslinking agent glutaraldehyde and regulator polyethylene glycol, and mix well as dispersed phase solution I, wherein, the added cross-linking agent glutaraldehyde accounts for 5% of the mass of the dispersed phase solution I obtained, and the added regulator polyethylene glycol accounts for 2% of the mass of the dispersed phase solution I obtained; the organic amine compound diethylenetriamine Dissolved in water to prepare a solution with a mass concentration of 5% as the dispersed phase solution II;

[0030] (2) Preparation of the continuous phase solution: adding the surfactant Span80 into the organic solvent liquid paraffin, mixing, and preparing an organic solution containing 1% of...

Embodiment 2

[0036] A preparation method of dithiocarbamate functionalized lignin microspheres, the operation steps are as follows:

[0037](1) Preparation of the dispersed phase solution: the hydrolyzed lignin is dissolved in water to prepare a hydrolyzed lignin aqueous solution with a mass percentage of 20%, then the crosslinking agent acetaldehyde and the regulator polyvinyl alcohol are added, and the mixture is uniformly used as the dispersed phase solution I, wherein, The cross-linking agent acetaldehyde added accounts for 6% of the quality of the dispersed phase solution I, and the regulator polyvinyl alcohol added accounts for 4% of the quality of the dispersed phase solution I obtained; organic amine compounds triethylenetetramine, ethylenediamine (three Ethylenetetramine and ethylenediamine (mixed at a mass ratio of 1:1) were dissolved in water to prepare a solution with a mass concentration of 9% as the dispersed phase solution II;

[0038] (2) Preparation of continuous phase sol...

Embodiment 3

[0044] A preparation method of dithiocarbamate functionalized lignin microspheres, the operation steps are as follows:

[0045] (1) Preparation of dispersed phase solution: Dissolve ethanol lignin in water to prepare an ethanol lignin aqueous solution with a mass percentage of 20%, then add crosslinking agent glyoxal and regulator water-soluble starch, and mix uniformly as dispersed phase solution I, wherein , the added crosslinking agent glyoxal accounts for 7% of the mass of the dispersed phase solution I obtained, and the added regulator water-soluble starch accounts for 8% of the mass of the dispersed phase solution I obtained; the organic amine compound polyethyleneimine is dissolved in water to prepare A solution with a mass concentration of 13% is used as the dispersed phase solution II;

[0046] (2) Preparation of the continuous phase solution: adding surfactants Tween80 and Span60 (Tween80 and Span60 are mixed in a mass ratio of 1:1) into the organic solvent hexadecan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com