Vehicle-use high-mesh-number extrusive-type SCR denitration catalyst and preparation method thereof

An SCR catalyst, extrusion technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

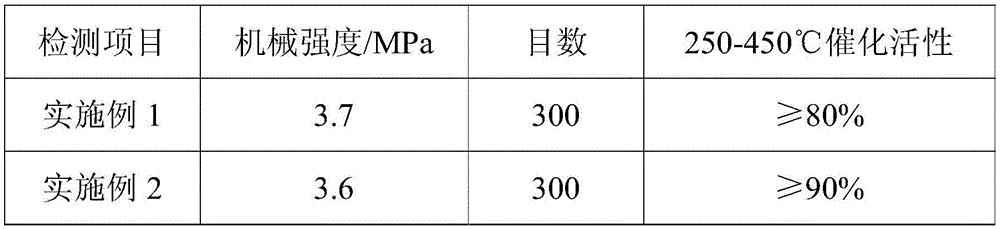

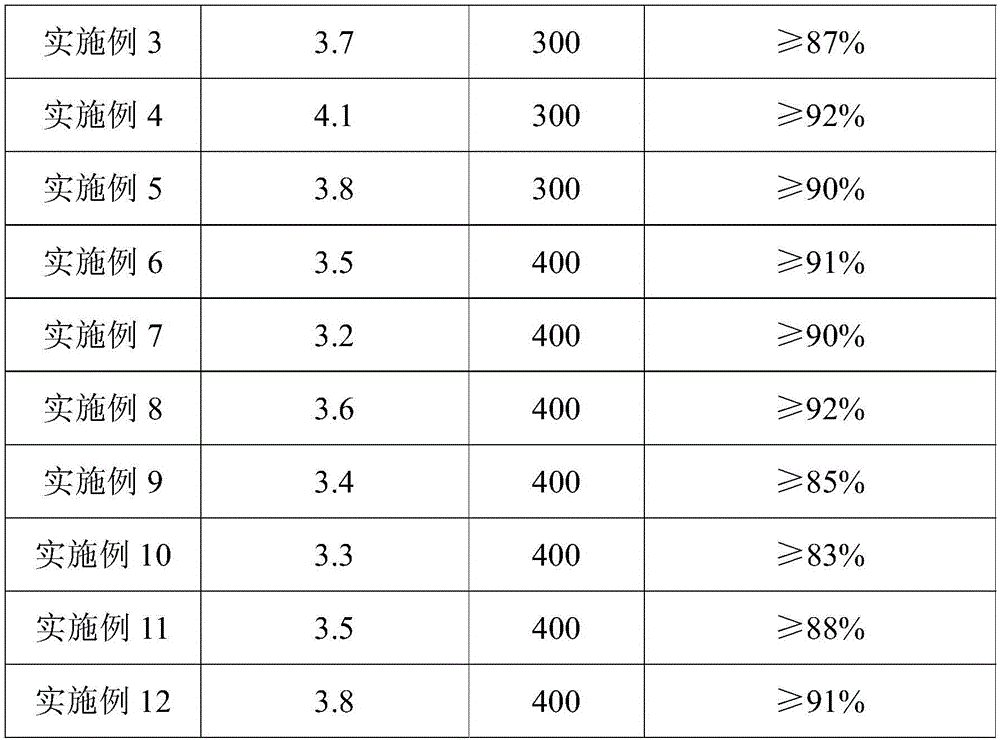

Examples

Embodiment 1

[0019] (1) Preparation of the catalyst precursor, ammonium metavanadate and oxalic acid were dissolved in deionized water at a molar ratio of 1:1, stirred with a mechanical stirrer, and dissolved completely at room temperature to prepare a catalyst precursor solution, the concentration 20%;

[0020] (2) Weigh 100 parts of titanium tungsten powder, 2 parts of hydroxypropyl methylcellulose, 1 part of polyethylene oxide, 2 parts of oleic acid, 1 part of chemical fiber, and 2 parts of gamma alumina, and add them to the kneader, Knead for 10-50 minutes to mix the raw materials evenly, then add 2 parts of ethylene glycol, 2 parts of lactic acid, 15 parts of catalyst precursor solution, 2 parts of ethanolamine, 2 parts of γ-alumina, 1 part of silica sol, and 4 parts of ammonia water, respectively Slowly add to the mud, and add 16 parts of deionized water, knead for 20-120min, and stale for 10-30h after kneading;

[0021] (3) Put the above-mentioned stale mud material in a vacuum mud...

Embodiment 2

[0025] (1) Preparation of the catalyst precursor, ammonium metavanadate and oxalic acid were dissolved in deionized water at a molar ratio of 1:1, stirred with a mechanical stirrer, and dissolved completely at room temperature to prepare a catalyst precursor solution, the concentration 20%;

[0026] (2) Weigh 100 parts of titanium tungsten powder, 7 parts of hydroxypropyl methylcellulose, 5 parts of polyethylene oxide, 5 parts of oleic acid, 7 parts of chemical fiber, and 10 parts of γ-alumina into the kneader, and knead for 10- 50min, mix the raw materials evenly, then slowly add 10 parts of ethylene glycol, 5 parts of lactic acid, 35 parts of catalyst precursor solution, 6 parts of ethanolamine, 10 parts of γ-alumina, 5 parts of silica sol, and 10 parts of ammonia water into the mud respectively , and add 1 part of deionized water, knead for 20-120min, and stale for 10-30h after kneading is completed;

[0027] (3) Put the above-mentioned obsolete mud material in a vacuum mu...

Embodiment 3

[0031] (1) Preparation of the catalyst precursor, ammonium metavanadate and oxalic acid were dissolved in deionized water at a molar ratio of 1:1, stirred with a mechanical stirrer, and dissolved completely at room temperature to prepare a catalyst precursor solution, the concentration 20%;

[0032] (2) Weigh 100 parts of titanium tungsten powder, 3 parts of hydroxypropyl methylcellulose, 2 parts of polyethylene oxide, 3 parts of oleic acid, 2 parts of chemical fiber, and 3 parts of γ-alumina and add them to the kneader, and knead for 10- 50min, mix the raw materials evenly, then slowly add 3 parts of ethylene glycol, 3 parts of lactic acid, 30 parts of catalyst precursor solution, 3 parts of ethanolamine, 3 parts of γ-alumina, 2 parts of silica sol, and 5 parts of ammonia water into the mud respectively , and add 4 parts of deionized water, knead for 20-120min, stale for 10-30h after kneading;

[0033] (3) Put the above-mentioned stale mud material in a vacuum mud refining m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com