Odorless asphalt base waterproof material

A waterproof material, bitumen-based technology, used in epoxy resin coatings, coatings, etc., can solve the problems of poor energy saving performance, limited effect, irritating odor, etc., to increase mechanical strength and flame retardant performance, avoid indoor temperature. The effect of loss and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

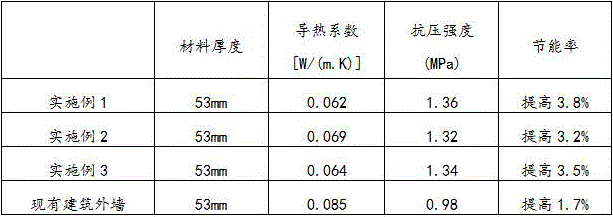

Embodiment 1

[0022] An odorless asphalt-based waterproof material, comprising a base layer and an insulation layer, the insulation layer is coated on the base layer, and the base layer includes the following raw materials in parts by weight: 3 parts of sepiolite, 25 parts of quartz sand, 4 parts of mineral fiber , 1 part of silicate, 2 parts of calcium carbonate powder, 6 parts of perlite powder, 2 parts of anti-cracking agent, 8 parts of polystyrene particles, 3 parts of 10# asphalt, 12 parts of wetting agent, 5 parts of carbon black, nitrile group 3 parts of butadiene rubber granules, 12 parts of 90# asphalt, 2 parts of cellulose powder; Described insulation layer comprises the raw material of following weight part: 8 parts of epoxy resin, 0.8 part of bamboo charcoal fiber, 2.5 parts of silicon acrylic emulsion, hydrogenated 0.3 parts of aluminum, 0.1 part of latex powder, 3 parts of water-based glue, 0.1 part of antifungal agent, 0.01 part of acid-base regulator, 4 parts of ethylene glyc...

Embodiment 2

[0033] An odorless asphalt-based waterproof material, comprising a base and an insulating layer, the insulating layer is coated on the base, and the base includes the following raw materials in parts by weight: 5 parts of sepiolite, 56 parts of quartz sand, and 6 parts of mineral fiber , 2 parts of silicate, 4 parts of calcium carbonate powder, 10 parts of perlite powder, 5 parts of anti-cracking agent, 10 parts of polystyrene particles, 5 parts of 10# asphalt, 24 parts of wetting agent, 13 parts of carbon black, nitrile 9 parts of butadiene rubber granules, 18 parts of 90# asphalt, 8 parts of cellulose powder; Described insulation layer comprises the raw material of following weight part: 10 parts of epoxy resins, 1.5 parts of bamboo charcoal fibers, 4 parts of silicon-acrylic emulsions, hydroxide 0.5 parts of aluminum, 0.5 parts of latex powder, 4 parts of water-based glue, 0.2 parts of antifungal agent, 0.02 parts of acid-base regulator, 4.5 parts of ethylene glycol, 0.5 par...

Embodiment 3

[0044] An odorless asphalt-based waterproof material, comprising a base layer and an insulation layer, the insulation layer is coated on the base layer, and the base layer includes the following raw materials in parts by weight: 4 parts of sepiolite, 40 parts of quartz sand, and 5 parts of mineral fiber , 1.5 parts of silicate, 3 parts of calcium carbonate powder, 8 parts of perlite powder, 3.5 parts of anti-cracking agent, 9 parts of polystyrene particles, 4 parts of 10# asphalt, 18 parts of wetting agent, 9 parts of carbon black, nitrile group 6 parts of butadiene rubber granules, 15 parts of 90# asphalt, 5 parts of cellulose powder; Described insulation layer comprises the raw material of following weight part: 9 parts of epoxy resins, 1.15 parts of bamboo charcoal fibers, 3.5 parts of silicon acrylic emulsion, hydrogenated 0.4 parts of aluminum, 0.3 parts of latex powder, 3.5 parts of water-based glue, 0.15 parts of antifungal agent, 0.015 parts of acid-base regulator, 4.25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com