Preparation of methylamine lead-iodine nanowire under air environment and application of photoelectric detector

An air environment, methylamine lead iodine technology, which is applied to the preparation of methylamine lead iodine nanowires in an air environment and the application field of photodetectors, can solve problems such as performance to be improved, and achieve the effect of improving photoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Pure phase MAPbI 3 The specific preparation process of nanowires.

[0025] Dissolve 0.227 g of lead iodide in 2 ml of DMF solution at room temperature to prepare a lead iodide precursor solution with a concentration of 0.3 mmol / ml.

[0026] Dissolve 17.5mg of MAI in 5ml of IPA solution to form a 17.5mg / 5ml solution of MAI and IPA.

[0027] After taking 5 μl of DMF solution and 200ul of 17.5mg / 5ml MAI and IPA solution with a pipette, mix the two solutions to obtain a mixed solution.

[0028] Use a pipette to take 20μl of 0.3mmol / ml lead iodide precursor solution, drop it on the clean glass base, place it on a spin coater, let it stand for 10s, and spread it evenly at a low speed of 2000r / 5s, then 6000r / The film was formed at a high speed of 5s without any heat treatment, and immediately spin-coated with 5μl of DMF and 200μl of MAI and IPA mixed solution at a speed of 4000r / 20s, and then heat-treated at 100°C to obtain MAPbI 3 Nanowires.

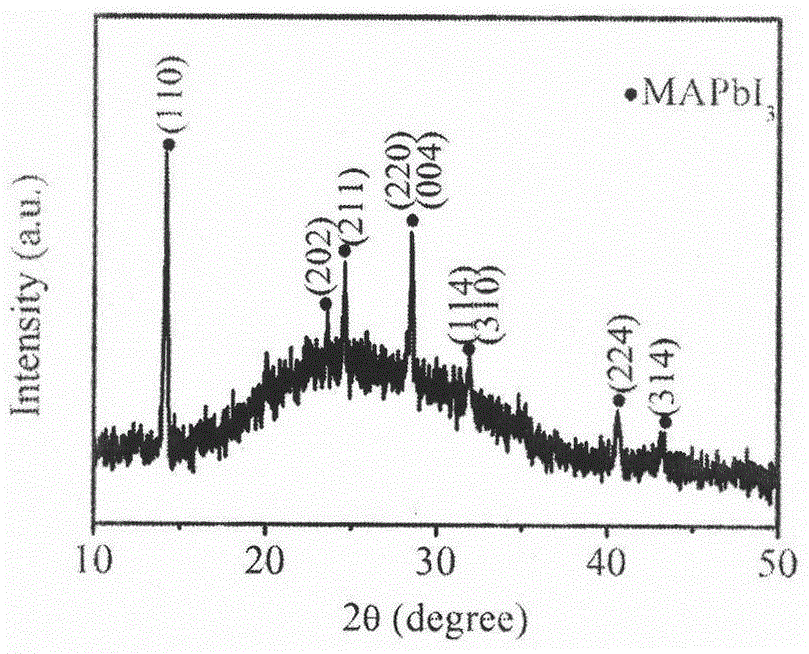

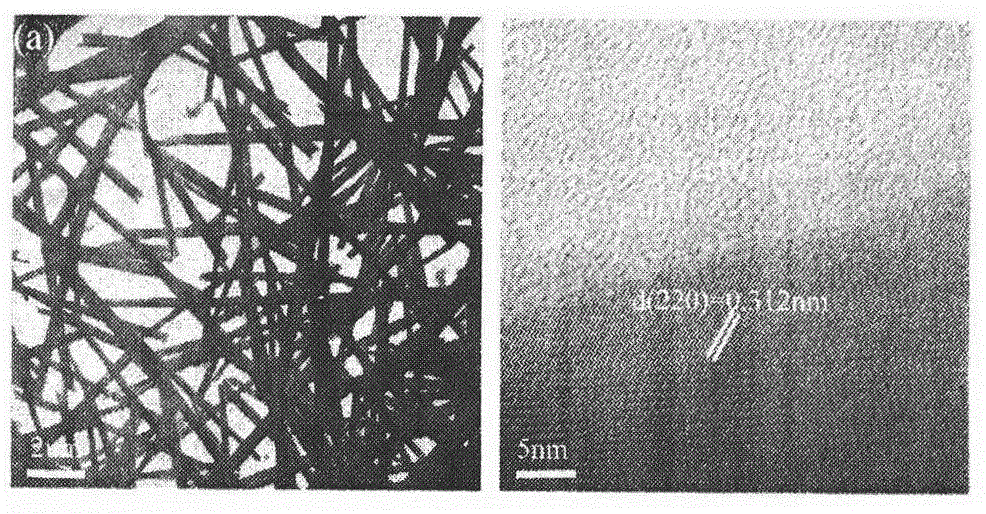

[0029] figure 1...

Embodiment 2

[0031] Example 2: MAPbI 3 The specific preparation process of nanowire morphology and size control.

[0032] The difference between this embodiment and Example 1 is that the concentration of lead iodide is different, respectively 0.1848g, 0.227g, 0.3696g and 0.462g of lead iodide are dissolved in 2ml of DMF solution at room temperature, the concentration is respectively 0.2mmol / ml , 0.3mmol / ml, 0.4mmol / ml and 0.5mmol / ml of lead iodide precursor prepared MAPbI 3 Nanowires.

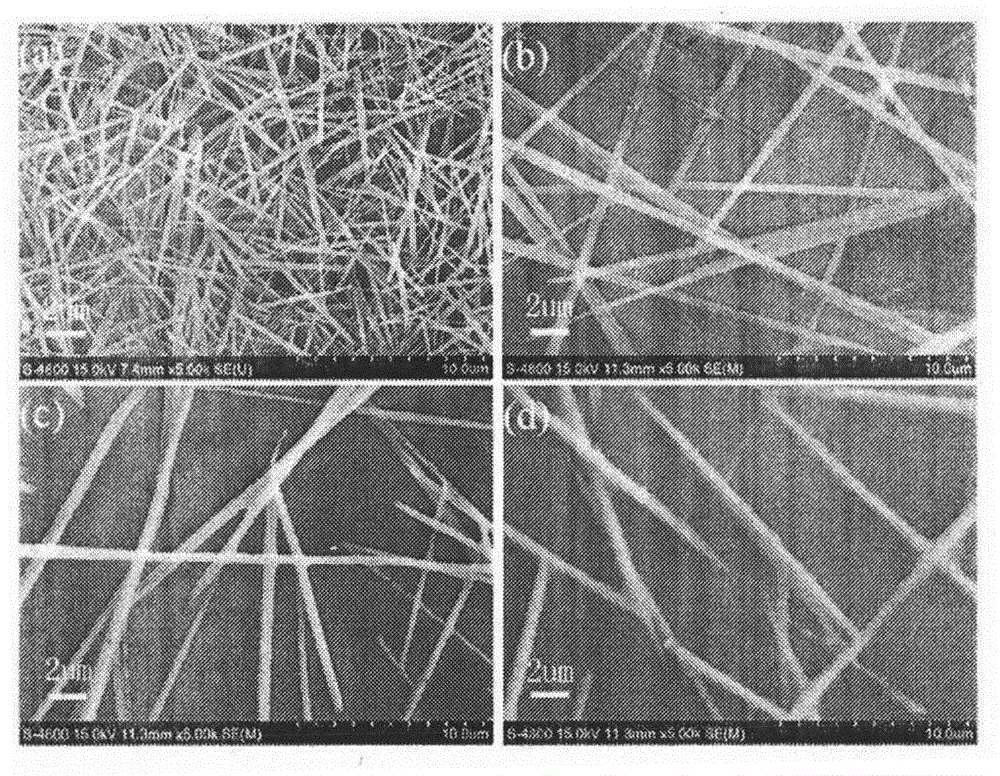

[0033] image 3 MAPbI prepared for different concentrations of lead iodide solutions 3 SEM images of nanowires. Figures (a), (b), (c) and (d) lead iodide concentrations are 0.2mmol / ml, 0.3mmol / ml, 0.4mmol / ml and 0.5mmol / ml respectively. It can be seen from the figure that with the change of the concentration of the lead iodide precursor, the prepared MAPbI 3The size and shape of the nanowires also changed. The nanowires at low lead iodide concentrations were slightly sparser, the length of the nanowir...

Embodiment 3

[0035] Example 3: MAPbI of different sizes and shapes 3 Fabrication process of nanowires for photodetector applications.

[0036] The difference between embodiment 3 and embodiment 2 is that the MAPbI with a concentration of 0.2mmol / ml, 0.3mmol / ml, 0.4mmol / ml and 0.5mmol / ml 3 The nanowires are grown on the cleaned interdigitated electrode substrate, and the probes with positive and negative electrodes are contacted with a pair of electrodes on the interdigitated electrodes, and the output current changes with time according to the voltage of 0.1V applied to both ends of the electrodes. Relational diagram, get I-T diagram of photoresponse.

[0037] Figure 5 MAPbI prepared for lead iodide solutions at different concentrations 3 Photoelectric response I-T diagram of nanowires. Figures (a), (b), (c) and (d) lead iodide concentrations are 0.2mmol / ml, 0.3mmol / ml, 0.4mmol / ml and 0.5mmol / ml in turn. From the figure, we can see that when the concentration of lead iodide is reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com