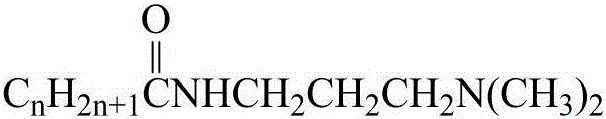

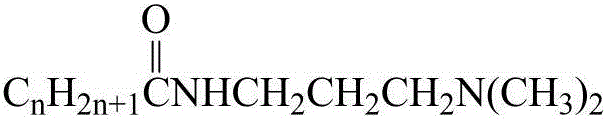

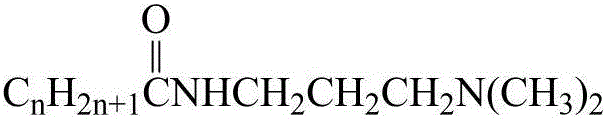

Fatty acid amide propyl dimethylamine refining method

A technology of fatty amidopropyl dimethyl tertiary amine and refining method, which is applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems of deep color and excessive dimethylaminopropylamine, and achieve low production cost and refined The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Add 3.12kg of dodecanoic acid, 31.2g of the original catalyst and 0.64g of reducing catalyst sodium borohydride in a 5L reactor heated by jacketed heat transfer oil, heat up (2L / min) under the protection of an inert gas (nitrogen), and melt Then start stirring, and add 1.5 kg of dimethylaminopropylamine dropwise at 160° C., and finish adding dropwise in 2 hours. The reaction was continued for 5 hours, and 386 g of water (containing dimethylaminopropylamine) was produced. Sampling was taken to measure the acid value. After the acid value was less than 5 mgKOH / g, 0.6 kg of dimethylaminopropylamine was added dropwise to the reactor, and the reaction was continued for 1 hour according to the original process conditions. Increase the flow of inert gas nitrogen (8L / min) to purge and wash from the bottom of the reactor, and the evaporated dimethylaminopropylamine enters the receiver after being condensed for feeding in the next batch. Wash until no dimethylaminopropylamine ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com