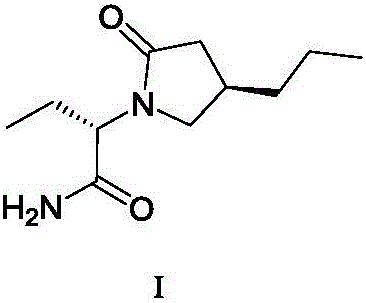

Method for preparing brivaracetam

A compound and solvent technology, applied in the field of preparation of brivaracetam, can solve the problems of low product purity, low total yield, unsuitable for industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066]

[0067] Dissolve (R)-3-methoxycarbonylhexanoic acid (174.1g, 1mol, ee value 99.2%) in 500mL methanol, cool to 0℃, add 500mL water, cool to 0℃, add powdered chlorine in turn An ethanol solution (2M, 800 mL) of calcium phosphate (115.8 g, 1.1 mol) and sodium borohydride. After the reaction solution was stirred overnight (about 12 hours) at room temperature (20℃~30℃), the reaction was quenched by adding hydrochloric acid (6M, 1000mL), concentrated under reduced pressure, diluted with 500mL water, and extracted with dichloromethane (3×150mL) The organic phases were combined, dried over anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain 108.9 g of Compound III, with a yield of 85.0%, and a purity of 97.2% (GC).

[0068] R-3-methoxycarbonylhexanoic acid can be prepared according to the method described in Angewandte Chemie International Edition, 1998, 37(13-14), 1931-1933, with an ee value greater than 99.0%.

Embodiment 2

[0070]

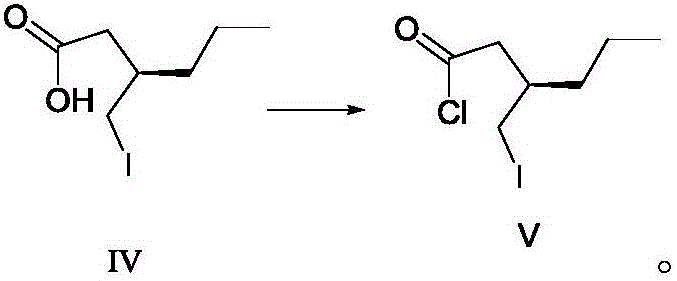

[0071] Under the protection of nitrogen, dissolve Buwaxitan Intermediate III (128.1g, 1mol) in 1L dichloromethane, lower the temperature to 0℃, add trimethylsilyl iodide (150mL), and keep the reaction solution at 20-30℃ Stir for 2 hours. Then add hydrochloric acid solution (1M, 800mL) and sodium thiosulfate aqueous solution (mass percentage is 10%, the mass percentage refers to the percentage of the mass of sodium thiosulfate to the total mass of sodium thiosulfate aqueous solution, 400mL.) , The aqueous phase was extracted with 1L of dichloromethane, the organic phase was washed twice with saturated brine, dried over anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain Buwaxitam intermediate IV (254.6g), yield 99.5%, purity : 95.6% (GC).

Embodiment 3

[0073]

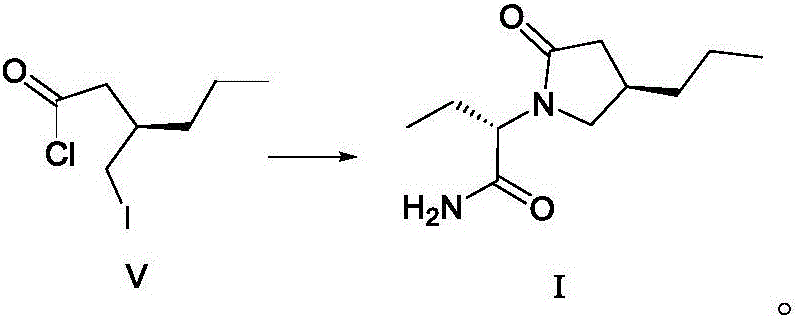

[0074] Under the protection of nitrogen, dissolve Buwaxitan intermediate IV (1280.4g, 4mol) in 1500mL toluene, slowly add thionyl chloride (951.8g, 8mol), and stir the reaction solution at room temperature (20℃~30℃) For 24 hours, the solvent was concentrated under reduced pressure. The residue was rectified under reduced pressure with a vacuum pump (0.32mmHg, 90-95°C) to obtain 1310g of compound V as a pale yellow transparent liquid.

[0075] The compound V 1310g obtained was dissolved in 2.5L dichloromethane solution, and then the above solution was added containing L-2-aminobutanamide hydrochloride (428.9g, 4.2mol), 4A molecular sieve (500g), potassium hydroxide (500g) ), anhydrous sodium sulfate (500g), tetrabutylammonium bromide (49g, 0.14mol) in dichloromethane solution (12.5L), the reaction solution was stirred at 20℃~30℃ for 18 hours and then added diatomaceous earth After filtration, the filtrate was concentrated to dryness under reduced pressure to obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com