Method for dissolving fiber of natural silk

A technology of natural silk and fiber, applied in the field of natural organic polymers, can solve the problems of serious degradation and complicated process, and achieve the effects of easy regeneration and processing, good processing performance, and simple and efficient dissolution process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

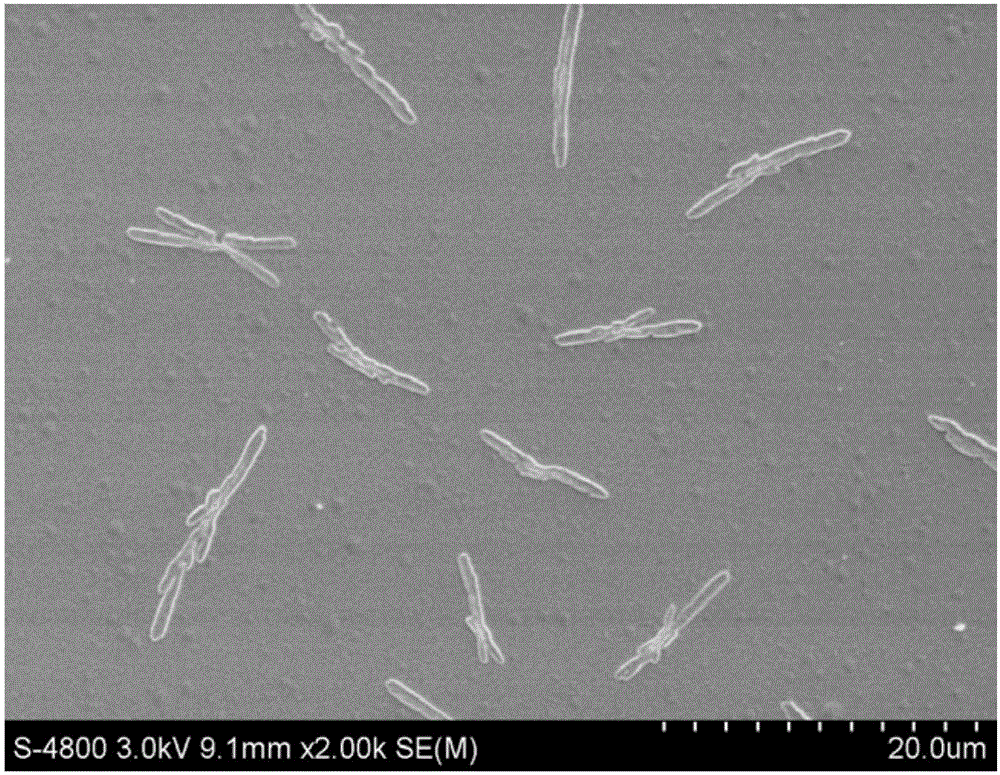

[0028] The natural mulberry silk was boiled with 0.5wt% sodium bicarbonate solution for 60 minutes, washed with deionized water and dried to obtain degummed mulberry silk. At 20°C, the degummed mulberry silk was placed in 50wt% trifluoroacetic acid aqueous solution, the silk mass fraction was 10%, and the regenerated silk fibroin protein solution was obtained after magnetic stirring for 10 min. figure 1 It is a scanning electron microscope image of the regenerated silk fibroin solution; it can be seen that the silk fibroin in the solution is fibrous, with a fiber length of 5-15 µm and a diameter of 0.5-3 µm. Under this dissolution condition, the dissolution effect is good, showing that the silk protein in the solution is mainly in the shape of nanofibers, and the fiber size is relatively uniform.

[0029] The regenerated silk fibroin protein solution was injected into a polyethylene dish, and the regenerated mulberry silk fibroin protein film was obtained after natural drying....

Embodiment 2

[0031] The natural mulberry silk was boiled with 0.05wt% sodium bicarbonate solution for 30 minutes, repeated three times, then fully washed with deionized water and dried to obtain degummed mulberry silk. Under the condition of 15°C, the degummed mulberry silk was placed in pure trifluoroacetic acid solvent, the silk mass fraction was 10%, and the regenerated silk fibroin protein solution was obtained after magnetic stirring for 20 min. Silk fibroin in the solution is fibrous, with a fiber length of 0.5-5µm and a diameter of 0.1-0.5µm, such as image 3 shown. Under this dissolution condition, silk is dissolved into a smaller-sized fibrous structure with uniform fiber size.

Embodiment 3

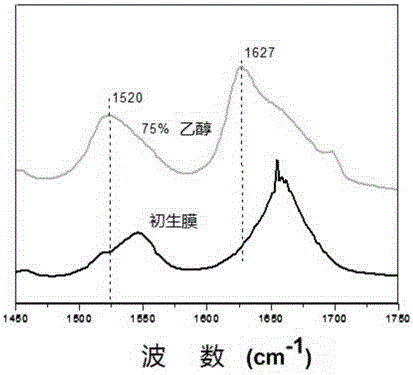

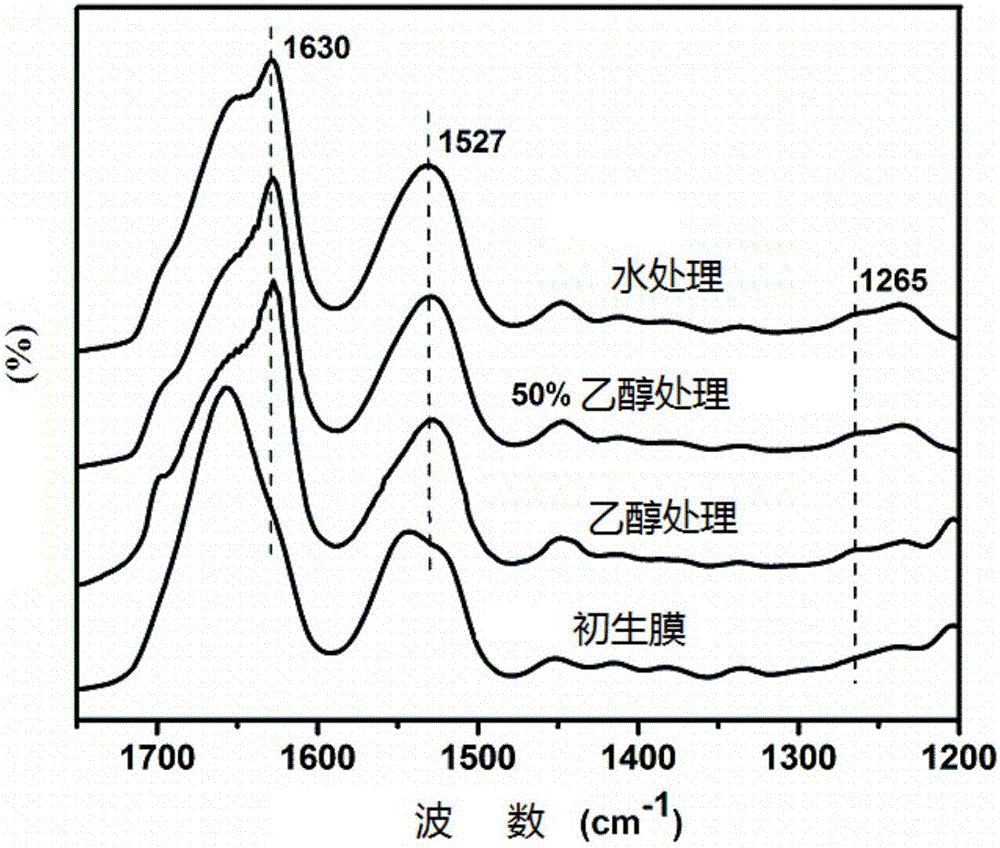

[0033] The natural tussah silk was boiled with 0.5wt% sodium carbonate solution for 30 minutes, repeated three times, fully washed with deionized water and dried to obtain degummed tussah silk. Under the condition of 37℃, the degummed tussah silk was placed in trifluoroacetic acid / formic acid (volume ratio 9 / 1), the mass fraction of tussah silk was 8%, and the regenerated tussah silk fibroin protein solution was obtained after magnetic stirring for 10 min. The solution was electrospun to obtain tussah silk fibroin nanofibers, the average fiber diameter was about 560nm, and the protein structure was an amorphous structure, which was transformed into a β-sheet crystal structure after ethanol treatment, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com