Method and Application of Surface Molecularly Imprinted Microspheres Prepared by Pickering Emulsion Polymerization Based on Hydrophobic Hydroxyapatite Nano-stabilized Particles

A technology of hydrophobic hydroxyapatite and surface molecular imprinting is applied in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc. Simple, Bioactive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 5.0 g of hydroxyapatite, add it into a three-necked bottle containing 150 mL of anhydrous toluene, and disperse for 30 minutes with the aid of ultrasonic waves. 2 mL of 3-(methacryloyloxy)propyltrimethoxysilane was slowly added dropwise to the system, and then reacted at 120° C. for 1 day under the protection of nitrogen. After cooling to room temperature, the unreacted silane coupling agent was washed away by centrifugation with toluene, and the obtained sample was vacuum-dried at 60° C. for 2 days to obtain hydrophobic hydroxyapatite nanoparticles.

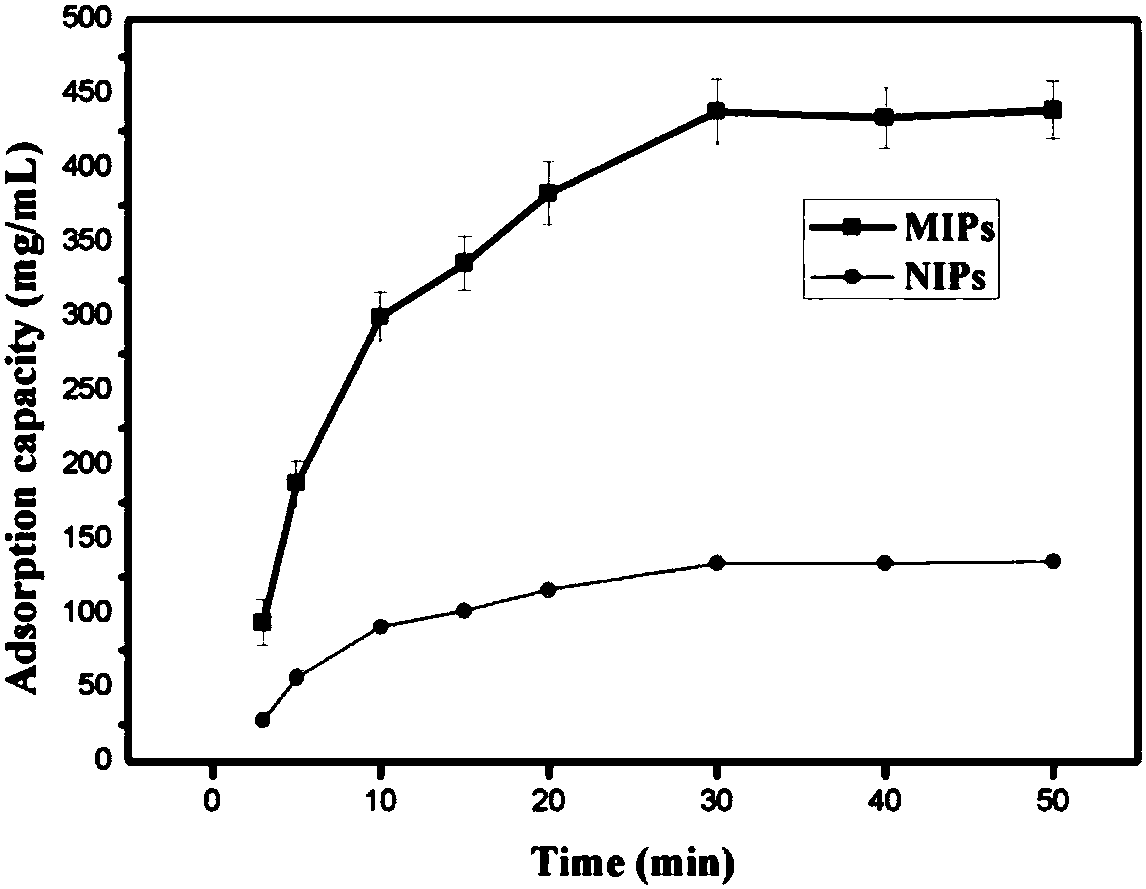

[0038] Weigh 170 mg of hydrophobic hydroxyapatite nanoparticles, add to 10 mL of toluene, and ultrasonically disperse for 30 minutes to obtain an oil phase. Weigh 20 mg of bovine hemoglobin, add it into 4 mL of PBS buffer (pH=7.4), oscillate to fully dissolve, then add 100 mg of dopamine hydrochloride, oscillate to fully dissolve, this is the water phase. The water phase and the oil phase were placed in the refrige...

Embodiment 2

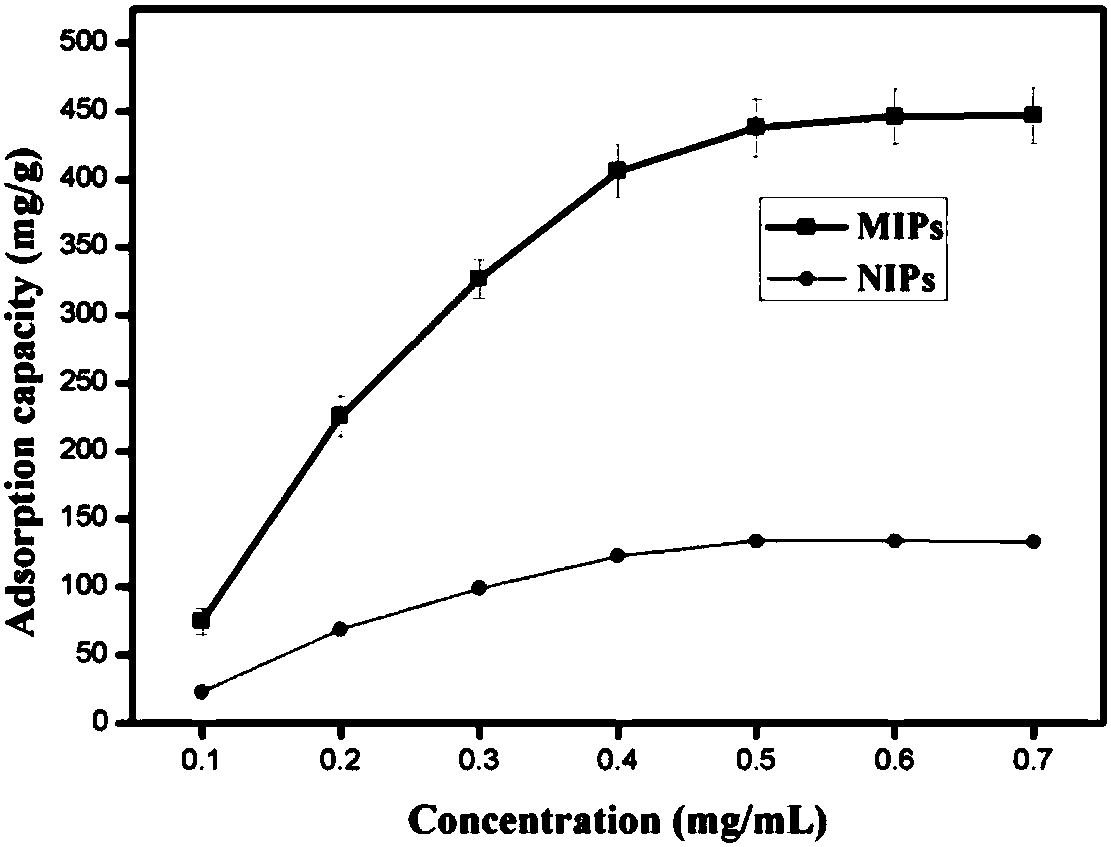

[0050] Weigh 120 mg of hydrophobic hydroxyapatite nanoparticles (prepared in Example 1), add into 8 mL of acetonitrile, and ultrasonically disperse for 20 minutes to obtain an oil phase. Weigh 15 mg of bovine hemoglobin, add it into 4 mL of PBS buffer (pH=8.5), oscillate to fully dissolve, then add 100 mg of dopamine hydrochloride, oscillate to fully dissolve, this is the water phase. The water phase and the oil phase were placed in the refrigerator for 20 minutes respectively, then mixed and shaken vigorously to form a stable Pickering emulsion. The obtained emulsion was polymerized at room temperature for 5 hours, the product was washed with acetonitrile and pure water, and then the template molecule was removed with an eluent (SDS: 5%, acetic acid: 10%) to obtain a molecular imprint with a specific site Polymer (MIP), non-molecularly imprinted and polymeric (NIP) were prepared without adding bovine hemoglobin, and the other steps were exactly the same. The adsorption test ...

Embodiment 3

[0052] Weighed 200 mg of hydrophobic hydroxyapatite nanoparticles (prepared in Example 1), added into 15 mL of toluene, and ultrasonically dispersed for 50 minutes to obtain an oil phase. Weigh 20 mg of bovine serum albumin, add it to 7 mL of PBS buffer (pH=10.0), oscillate to fully dissolve, then add 100 mg of dopamine hydrochloride, oscillate to fully dissolve, this is the water phase. The water phase and the oil phase were placed in the refrigerator for 30 minutes, then mixed and shaken vigorously to form a stable Pickering emulsion. The obtained emulsion was polymerized at room temperature for 8 hours, the product was washed with toluene and purified water, and then the template molecule was removed with an eluent (SDS: 10%, acetic acid: 6%) to obtain a molecular imprint with a specific site Polymer (MIP), non-molecularly imprinted and polymer (NIP) were prepared without adding bovine serum albumin, and the other steps were exactly the same. The adsorption test was the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com