Single-component epoxy modified silicone sealant and preparation method thereof

An epoxy modification and silicone technology, applied in epoxy resin adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of poor adhesion, poor compatibility, and high surface energy, and improve the adhesion Force and elasticity, improve extrusion, improve cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

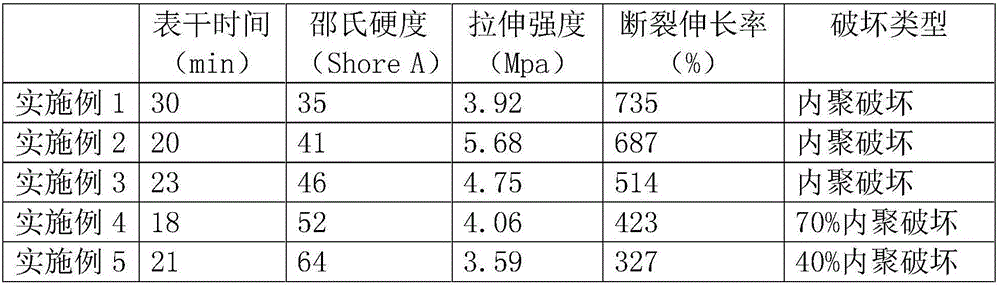

Examples

Embodiment 1

[0047] (1) Add 100 parts of silane-modified polyether resin, 10 parts of bisphenol-A epoxy resin E44, 50 parts of polyethylene glycol with an average molecular weight of 2000, and 100 parts of nano-calcium carbonate into the double planetary dynamic mixing in batches In the barrel, stir evenly and heat to 120°C, dehydrate for 1.5 hours at a vacuum of 0.099Mpa, and rotate at 500rpm.

[0048] (2) Cool down to room temperature with cooling water at a speed of 300 rpm.

[0049] (3) Add 2 parts of methyltrimethoxysilane and 2 parts of aminopropyltrimethoxysilane into the mixing tank of the planetary machine in batches, and stir for 20 minutes at a vacuum degree of 0.099Mpa at a rotation speed of 400rpm.

[0050] (4) Add 2 parts of dibutyltin dioctoate, stir for 30 minutes at a vacuum degree of 0.099Mpa and a rotation speed of 400rpm, and then pack and discharge to obtain a one-component epoxy-modified silicone sealant.

Embodiment 2

[0052] (1) Add 100 parts of silane-modified polyether resin, 20 parts of bisphenol A epoxy resin E51, 75 parts of polypropylene glycol with an average molecular weight of 2000, and 170 parts of nano-calcium carbonate into the barrel of the double planetary dynamic mixer in batches Inside, after stirring evenly, heat to 120°C, dehydrate for 1 hour under a vacuum of 0.099Mpa, and rotate at 800rpm.

[0053] (2) Cool down to room temperature with cooling water at a speed of 400 rpm.

[0054] (3) Add 2.5 parts of methyltriethoxysilane and 4 parts of aminopropyltriethoxysilane in batches into the mixing tank of the planetary machine, and stir for 20 minutes at a vacuum degree of 0.099Mpa at a rotation speed of 500rpm.

[0055] (4) Add 3 parts of ethyl acetoacetate organotin chelate, stir for 30 minutes at a vacuum of 0.099 MPa and a rotation speed of 400 rpm, then pack and discharge to obtain a one-component epoxy-modified silicone sealant.

Embodiment 3

[0057] (1) 100 parts of silane-modified polyether resins, 30 parts of bisphenol A type epoxy resin E45, 110 parts of polytetrahydrofuran glycol with an average molecular weight of 3000, and 270 parts of nanometer calcium carbonate were added in batches. In the barrel of planetary power mixer, stir evenly, heat to 120°C, dehydrate for 2 hours at a vacuum of 0.099Mpa, and rotate at 600rpm.

[0058] (2) Cool down to room temperature with cooling water at a speed of 500 rpm.

[0059] (3) Add 4 parts of methyltrimethoxysilane and 2 parts of aminopropyltrimethoxysilane into the mixing tank of the planetary machine in batches, and stir for 20 minutes at a vacuum degree of 0.099Mpa at a rotation speed of 400rpm.

[0060] (4) Add 2 parts of dibutyltin dioctoate, stir for 30 minutes at a vacuum degree of 0.099Mpa and a rotation speed of 400rpm, and then pack and discharge to obtain a one-component epoxy-modified silicone sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com