A long-lasting superhydrophobic wear-resistant ceramic coating

A wear-resistant ceramic and super-hydrophobic technology, applied in coatings, ceramic products, devices for coating liquids on the surface, etc., can solve the problems of poor wear resistance, poor hydrophobic durability, etc. the effect of increasing the surface gas reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Ceramic coating preparation

[0039] (1) Metal substrate surface pretreatment:

[0040] Use sand blasting technology to derust the surface of the steel plate, put it into 80% ethanol solution for ultrasonic cleaning, remove the surface grease, dust and other impurities, take it out and dry it naturally, and keep it for later use;

[0041] (2) Preparation of bottom layer and surface emulsion:

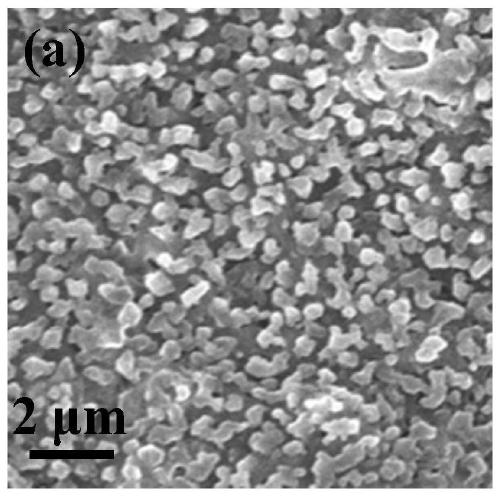

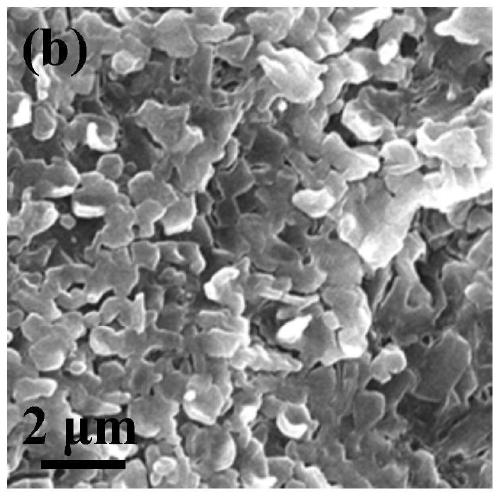

[0042] Evenly disperse 2 parts of dopamine and 5 parts of carbon nanotubes in 100 parts of water and magnetically stir for 60 minutes, add 40 parts of alumina ceramic emulsion to the above mixed solution under ultrasonic conditions, and obtain a uniform bottom emulsion after 60 minutes of ultrasonic dispersion . Electron microscope comparative analysis was carried out before and after the hydration of the ceramic particles in the bottom emulsion, and the results are shown in the attached Figure 1a and attached Figure 1b . Add 30 parts of polytetrafluoroethylene (PTFE) emu...

Embodiment 2

[0057] 1. Ceramic coating preparation

[0058] (1) Metal substrate surface pretreatment:

[0059] Use sandblasting technology and chemical etching to derust the surface of the steel plate, put it into 80% ethanol solution for ultrasonic cleaning, remove the surface grease, dust and other impurities, take it out and dry it naturally, and keep it for later use;

[0060] (2) Preparation of bottom layer and surface emulsion:

[0061] 3 parts of KH570, 5 parts of titanium nanowires and 5 parts of zinc oxide nanowires were uniformly dispersed in 80 parts of water solvent and magnetically stirred for 60 minutes, and 20 parts of alumina ceramic emulsion and 10 parts of nanometer yttrium oxide were added to the In the above mixed solution, a uniform bottom emulsion was obtained after 60 minutes of ultrasonic dispersion. Add 40 parts of polyvinylidene fluoride (PVDF) emulsion to 60 parts of water for magnetic stirring, the operating temperature is about 25°C at room temperature, and t...

Embodiment 3

[0074] 1. Ceramic coating preparation

[0075] (1) Metal substrate surface pretreatment:

[0076] Use 240-mesh sandpaper steel plate surface for derusting treatment, put it into 80% ethanol solution for ultrasonic cleaning, remove surface grease, dust and other impurities, take it out and dry it naturally, and keep it for later use;

[0077] (2) Preparation of bottom layer and surface emulsion:

[0078] 3 parts of KH560 and 9 parts of carbon nanofibers were uniformly dispersed in 50 parts of water solvent and magnetically stirred for 60 minutes, and 20 parts of alumina ceramic emulsion and 20 parts of nano-zirconia dispersion were added to the above mixed solution under ultrasonic conditions, After 60 minutes of ultrasonic dispersion, a uniform bottom emulsion was obtained. Add 20 parts of perfluoroethylene propylene copolymer (FEP) emulsion into water and carry out magnetic stirring. The operating temperature is about 25°C at room temperature, and the stirring time is 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com