Woven vascular drug stent

A blood vessel and drug technology, applied in the field of medical devices, can solve problems such as high stenosis rate, ineffective treatment of diabetic patients, and increased risk of stent thrombosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

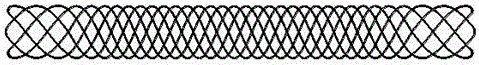

[0028] The material of the stent wire is nickel-titanium shape memory alloy, and the metal wire is braided into a stent. The structure is as follows: figure 1 shown.

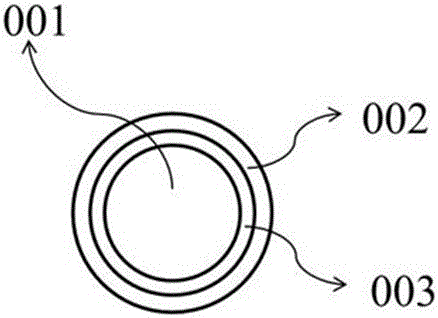

[0029] Take 0.1g of poly D, L-lactic acid (PDLLA, the weight average molecular weight range is 30,000-140,000), dissolve it in 10ml of n-propyl acetate at room temperature, and prepare a uniform solution, then add 0.1g of rapamycin Mix evenly, and accurately spray the configured solution onto the surface of the stent as the bottom layer of the drug coating of the stent. Then take 0.1g polyvinylpyrrolidone (PVP, the weight average molecular weight range is 30,000-200,000), add it to 10ml water to dissolve at room temperature, prepare a uniform solution, and spray it on the surface of the above-mentioned stent containing the bottom layer of the drug coating, as Protective top layer. The stent was dried in a vacuum oven, sterilized by ethylene oxide for use, and the coating structure was as follows: figure 2 sh...

Embodiment 2

[0032] The material of the stent wire is the same as in Example 1, and the metal wire is braided into a stent, and the structure is as follows figure 1 shown.

[0033] Take 0.1g of poly(lactic-co-glycolic acid) (poly(lactic-co-glycolic acid) (PLGA, the weight average molecular weight range is 20,000-80,000), dissolve in 10mL tetrahydrofuran at room temperature, prepare a uniform solution, and then add Mix 0.1g of paclitaxel evenly, spray the prepared solution onto the surface of the stent accurately, and use it as the bottom layer of the drug coating of the stent. The stent is dried in a vacuum oven, sterilized by ethylene oxide, and the coating structure is as follows: figure 2 shown. Then take 0.1g of polyethylene glycol (PEG, with a weight average molecular weight range of 10,000-30,000), dissolve it in 10ml of tetrahydrofuran at room temperature, prepare a uniform solution, and spray it on the surface of the stent containing the bottom layer of the drug coating as a prot...

Embodiment 3

[0036] The material of the stent wire is the same as in Example 1, and the metal wire is braided into a stent, and the structure is as follows figure 1 shown.

[0037] Take 0.1g of poly(lactic-co-glycolic acid) (poly(lactic-co-glycolic acid) (PLGA, the weight average molecular weight range is 20,000-80,000), dissolve in 10mL tetrahydrofuran at room temperature, prepare a uniform solution, and then add Mix 0.1g of paclitaxel evenly, spray the prepared solution onto the surface of the stent accurately, and use it as the bottom layer of the drug coating of the stent. The stent is dried in a vacuum oven, sterilized by ethylene oxide, and the coating structure is as follows: figure 2 shown. Then take 0.1g of polyethylene glycol (PEG, with a weight average molecular weight range of 10,000-30,000), dissolve it in 10ml of tetrahydrofuran at room temperature, and prepare a uniform solution, then add 0.1g of glibenclamide, spray to the above-mentioned drug-containing Coat the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com