Bi-component quick haemostatic gel and application thereof

A hemostatic gel, two-component technology, applied in the field of two-component rapid hemostatic gel, can solve the problems of poor mechanical strength and tissue binding force of the gel, and achieves reduction of gel formation time, simple usage, and biological safety. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

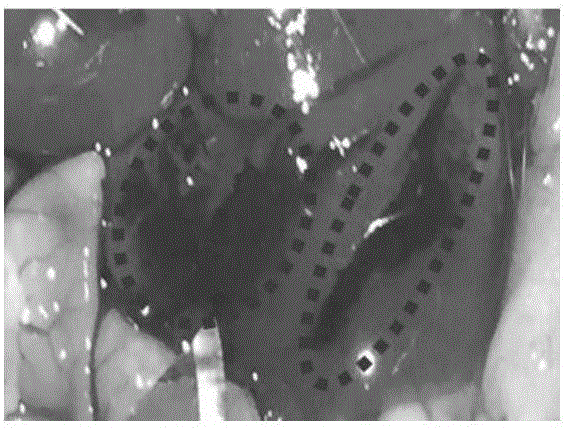

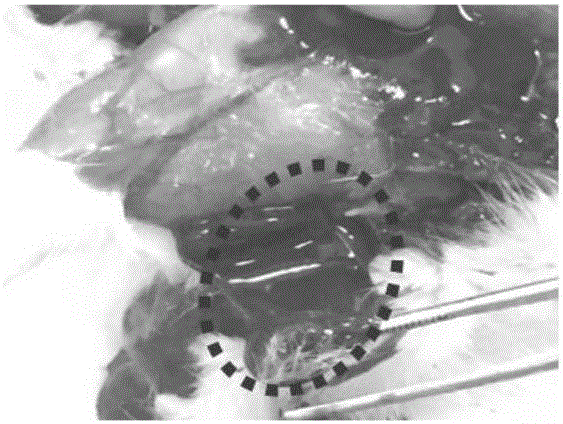

Image

Examples

Embodiment 1

[0026] 1) Dissolve 1g of chitosan in 100ml of water with a pH of 6 to prepare a solution with a mass concentration of 1%. After it is completely dissolved, add 0.5g of sodium periodate, react in the dark at 20°C for 1 hour, and then add 0.9ml of ethylene glycol Stop the reaction. Pour the reaction solution into a dialysis bag (molecular weight permeation 8000-14000Da) with deionized water as the dialysate, dialyze at 15°C for 2 days, then take the retentate and store it at -20°C for 0.5 hours, then store it at -80°C Stand for 5 hours, then freeze-dry in a freeze dryer at -50°C and 1Pa for 24 hours to obtain aldehydated chitosan, the oxidation rate of aldehyde groups (that is, the theoretical mass content of aldehyde groups accounts for the mass of aldehylated natural polysaccharides) 40%.

[0027] 2) Dissolve 1 mmol of hyaluronic acid in 100 ml of deionized water, and then add 1 mmol of hydrazine. After complete mixing, a mixture of 1 mmol of 1-(3-dimethylaminopropyl)-3-ethy...

Embodiment 2

[0030] 1) Dissolve 10g of dextran in 100ml of deionized water to prepare a solution with a mass concentration of 10%. After it is completely dissolved, add 10g of sodium perchlorate and react in the dark at 25°C for 3 hours, then add 9ml of ethylene glycol to terminate the reaction. Pour the reaction solution into a dialysis bag (molecular weight permeation 8000-14000Da) with deionized water as the dialysate, dialyze at 25°C for 7 days, then store it at -20°C for 3 hours, then place it at -80°C for 12 hours , and then lyophilized in a freeze dryer under the conditions of -50°C and 99Pa for 96 hours to obtain aldylated dextran, and the oxidation rate of the aldehyde group was 50%.

[0031] 2) Dissolve 1 mmol of gelatin (purchased from sigma) in 100 ml of deionized water, and then add 30 mmol of adipic acid dihydrazide. After complete mixing, a mixture of 5 mmol 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and 5 mmol 1-hydroxybenzotriazole hydrate (HOBt) was...

Embodiment 3

[0034] 1) Dissolve 2g of hyaluronic acid in 100ml of deionized water to prepare a solution with a mass concentration of 2%. After it is completely dissolved, add 2g of potassium periodate, react in the dark at 30°C for 12 hours, and then stop with 1.8ml of ethylene glycol reaction. Pour the reaction solution into a dialysis bag (molecular weight permeation 8000-14000Da) with deionized water as the dialysate, dialyze at 15°C for 4 days, then store it at -20°C for 1.5 hours, then place it at -80°C for 10 hours , and then lyophilized in a freeze dryer under the conditions of -50° C. and 50 Pa for 48 hours to obtain alhyallated hyaluronic acid, and the oxidation rate of the aldehyde group was 42%.

[0035] 2) Dissolve 1 mmol of sodium alginate in 100 ml of deionized water, and then add 15 mmol of adipic acid dihydrazide. After complete mixing, a mixture of 3 mmol 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and 3 mmol N-hydroxysuccinimide (NHS) was added to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com