Method for performing fast in-situ conversion on microfiltration or ultrafiltration membrane into nanofiltration membrane

A technology of ultrafiltration membrane and nanofiltration membrane, which is applied in the field of membrane separation, can solve the problems of graphene oxide nanofiltration membrane application limitation, limited application, harsh reaction conditions, etc. Effect of unrestricted, high water flux and salt rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

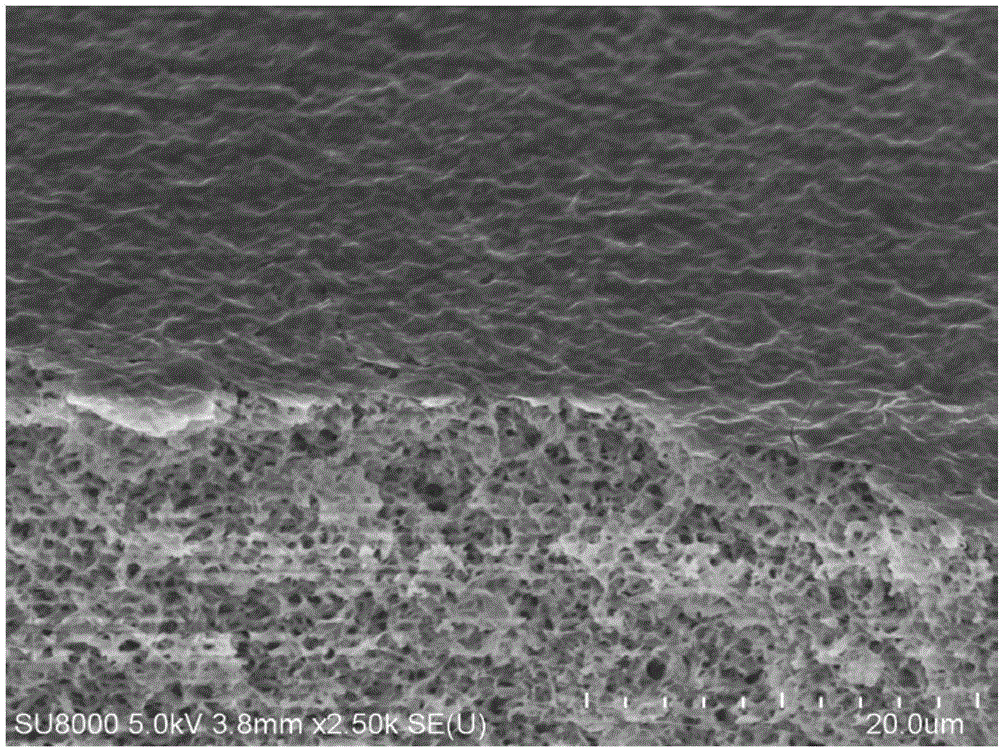

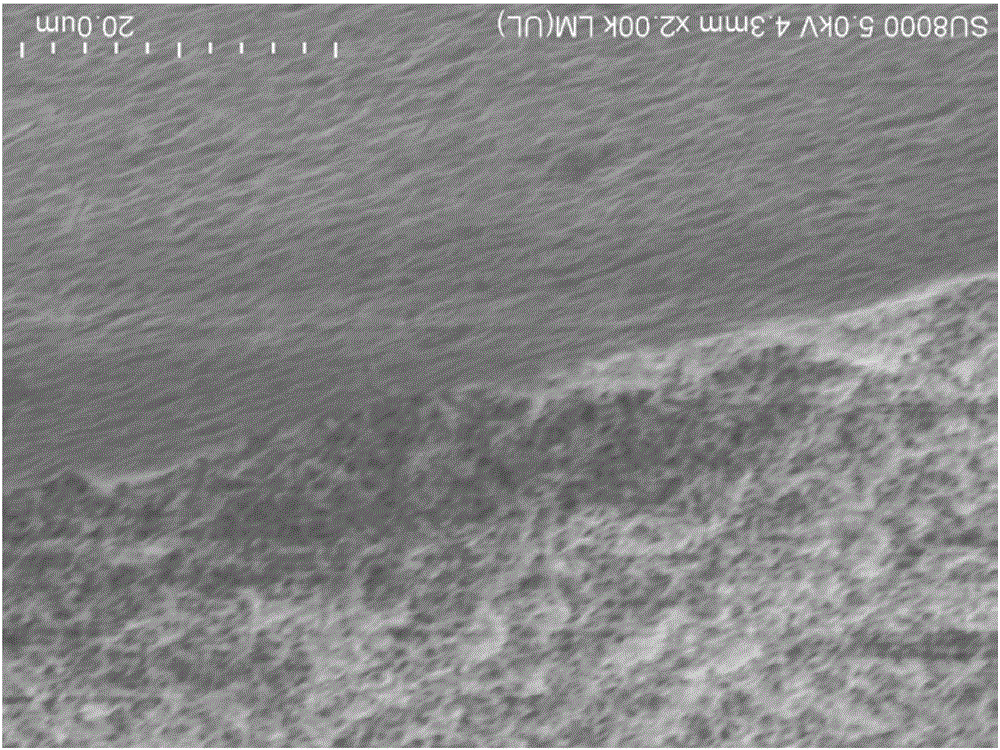

Embodiment 1

[0022] (1) Preparation of graphene oxide solution

[0023] The graphene oxide solution used in the present invention is prepared by using graphite powder as a raw material through the improved Hummer method combined with the peeling effect of ultrasonic treatment. The preparation process is as follows, 1g of graphite powder is put into a beaker, and 60mL of concentrated sulfuric acid and 0.5g of sodium nitrate are added into the beaker. Then, under ice-water bath and stirring condition, to the above mixture, slowly add 3g of potassium permanganate (KMnO 4 ), the whole process temperature is controlled below 20°C. After completing the addition of potassium permanganate, transfer to a water bath at 35° C. for constant temperature reaction for 10 hours, add 3 g of potassium permanganate again, and continue constant temperature reaction for 12 hours. After the oxidation reaction, under the conditions of ice-water bath and stirring, slowly add deionized water to 500mL, during thi...

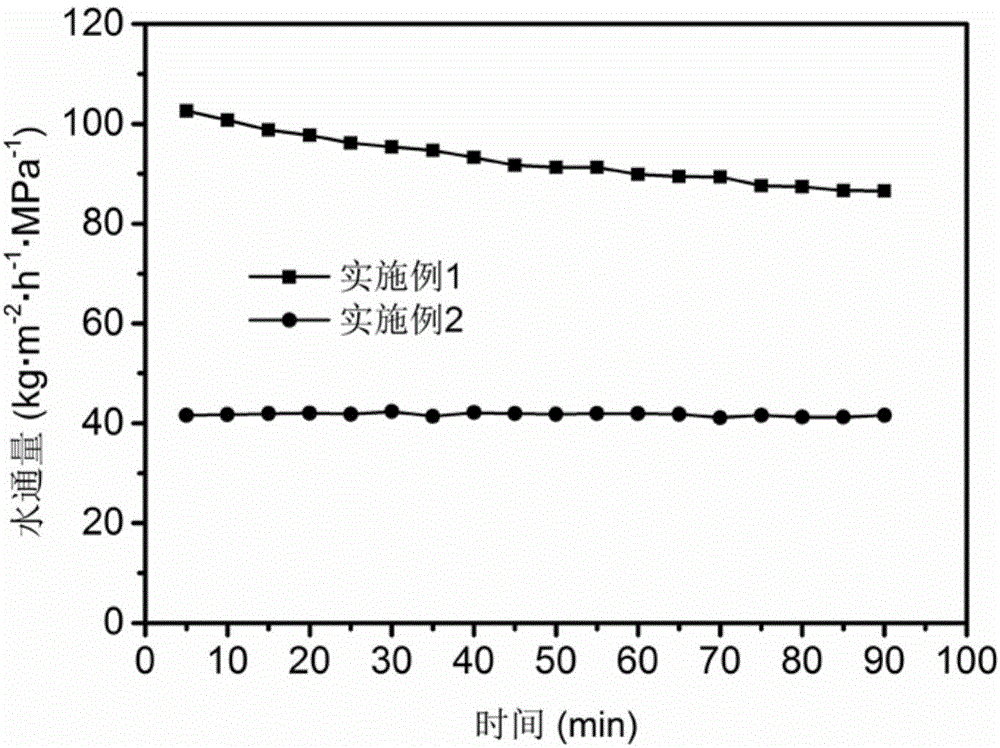

Embodiment 2

[0033] Nanofiltration membrane II was prepared according to the method of Example 1, except that the amount of diamine-crosslinked graphene oxide solution used was 50 mL. The nanofiltration membrane two is prepared and tested on the device described in the above-mentioned embodiment 1, and the water flux of the nanofiltration membrane prepared by the method of embodiment 2 is 41.6kg m -2 h -1 · MPa -1 , the removal rate of NaCl is 42.4%, for Na 2 SO 4 The removal rate of methyl orange is 81.5%, and the removal rate of methyl orange is 96.6%.

Embodiment 3

[0035] The third nanofiltration membrane was prepared according to the method of Example 1, except that the amount of the diamine-crosslinked graphene oxide solution was 15 mL. Nanofiltration membrane three is prepared and tested on the device described in the above-mentioned embodiment 1, and the result shows that the water flux of the nanofiltration membrane prepared in embodiment 3 is 162.5kg m -2 h -1 · MPa -1 , the removal rate of NaCl is 22.6%, for Na 2 SO 4 The removal rate of methyl orange is 56.7%, and the removal rate of methyl orange is 80.5%.

[0036] The results of Examples 1 to 3 show that the method of the present invention can be used to adjust the thickness of the graphene oxide film by changing the amount of the graphene oxide solution modified by diamine, and prepare graphite oxide with high water flux or better separation performance ene nanofiltration membranes to meet the needs of different uses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com