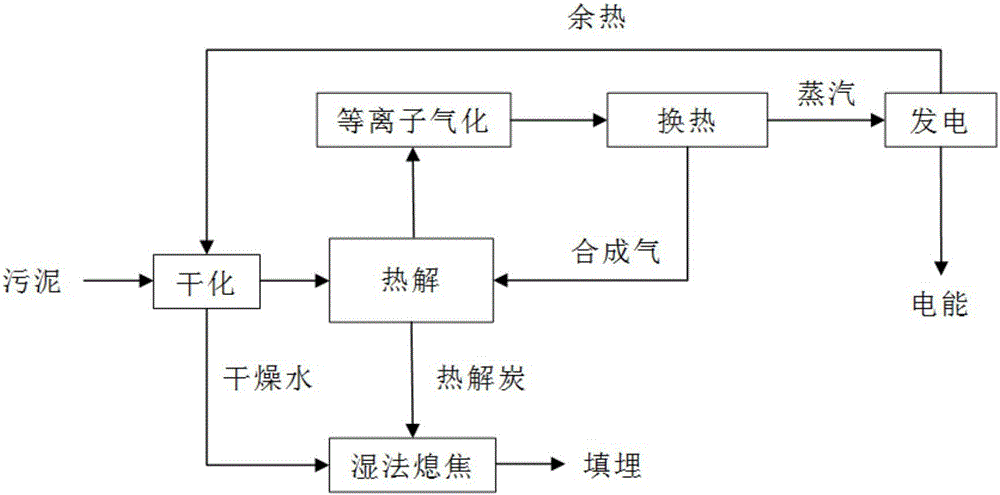

Method and system for sludge pyrolysis plasma gasifying generation

A plasma and pyrolysis gas technology, applied in gasification process, pyrolysis treatment of sludge, spiral gasifier, etc., can solve problems such as shortage of human resources, achieve low cost, high yield, and no pipeline blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

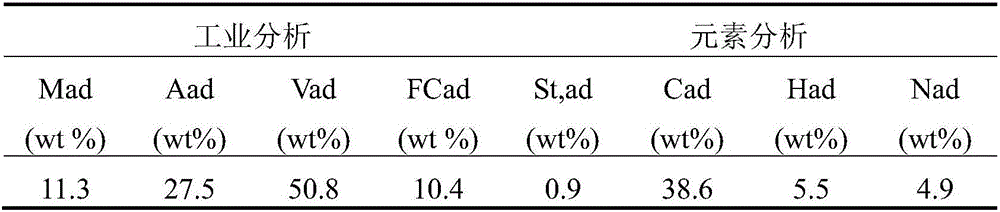

[0063] The above-mentioned sludge pyrolysis plasma gasification power generation system was used to treat the sludge of a certain urban sewage treatment plant. The industrial analysis and elemental analysis are shown in Table 1.

[0064] Table 1 Industrial analysis and elemental analysis of sludge

[0065]

[0066] M in this article ad Represents air-dry basis moisture; A ad Represents dry basis ash; V ad Represents volatile matter on an air-dry basis; F Cad Represents carbon content; S t,ad Represents total sulfur; C ad stands for carbon content; H ad represents the hydrogen content; N ad represents the nitrogen content.

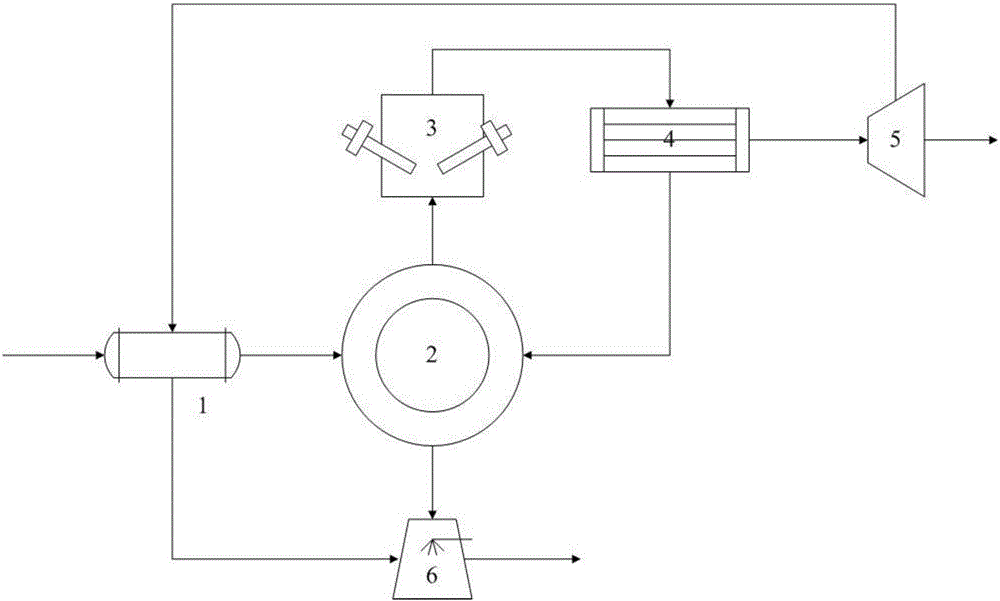

[0067] The specific treatment process is as follows: the moisture content of the sludge is 85%, and the sludge is sent to a drying device to obtain about 40% dry water. The dried sludge with moisture content reduced to 45% is sent to the regenerative rotary bed, and the temperature of the regenerative radiant tube in the pyrolysis zone is 700°C. ...

Embodiment 2

[0070] Using the sludge pyrolysis plasma gasification power generation system to treat the sludge of a certain urban sewage treatment plant, its industrial analysis and elemental analysis are shown in Table 2, and the specific treatment process is as follows:

[0071] Table 2 Industrial analysis and elemental analysis of sludge

[0072]

[0073] The moisture content of the sludge is 91%, and the sludge is sent to a drying device to obtain about 45% dry water. The dried sludge with moisture content reduced to 46% is sent to the regenerative rotating bed, and the temperature of the regenerative radiant tube in the pyrolysis zone is 800°C. After the sludge is pyrolyzed in the rotating bed, the final pyrolysis gas-liquid mixture is discharged from the top of the end of the regenerative rotating bed pyrolysis zone and enters the plasma gasification reaction chamber. The device is discharged, wherein the temperature of the plasma gasification reaction chamber is 1500°C. After t...

Embodiment 3

[0076] Using the sludge pyrolysis plasma gasification power generation system to treat the sludge of a certain urban sewage treatment plant, its industrial analysis and elemental analysis are shown in Table 3, and the specific treatment process is as follows:

[0077] Table 3 Industrial analysis and elemental analysis of sludge

[0078]

[0079] The moisture content of the sludge is 91%, and the sludge is sent to a drying device to obtain about 45% dry water. The dried sludge with moisture content reduced to 46% is sent to the regenerative rotary bed, and the temperature of the regenerative radiant tube in the pyrolysis zone is 500°C. After the sludge is pyrolyzed in the rotating bed, the final pyrolysis gas-liquid mixture is discharged from the top of the end of the regenerative rotating bed pyrolysis zone and enters the plasma gasification reaction chamber. The device is discharged, wherein the temperature of the plasma gasification reaction chamber is 1100°C. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com