Waterproof sizing agent for buildings

A technology for waterproof slurry and construction, which is applied in the field of construction powder and can solve the problems of secondary industrial pollution, polluted water sources, and inability to plant fertile fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

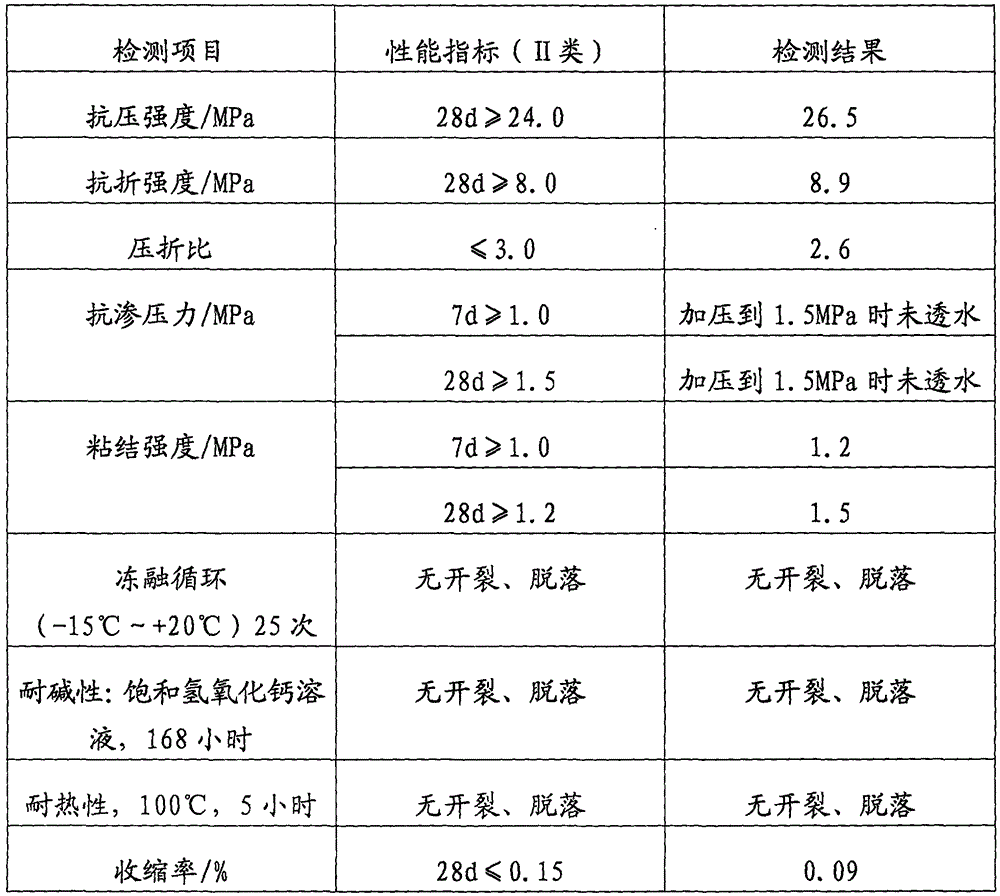

Examples

Embodiment 1

[0027] A waterproof slurry for construction, characterized in that the waterproof slurry includes waterproof emulsion and waterproof powder;

[0028] The waterproof powder includes the following raw materials by weight: 45 parts by weight of stone powder, 12 parts by weight of sand, 30 parts by weight of cement, 0.1 part by weight of water reducing agent, 0.1 part by weight of defoamer, 0.2 part by weight of anti-cracking agent, adhesive 0.1 part by weight of agent, 0.2 part by weight of dispersant, and 0.1 part by weight of auxiliary agent; said auxiliary agent includes gelling agent, water retaining agent, anti-alkali agent, retarder; wherein, said waterproof emulsion is anti-alkali waterproof emulsion. The alkali-resistant waterproof emulsion is an epoxy alkali-resistant primer emulsion. The water reducer is a naphthalene-based high-efficiency water reducer. The defoamer is emulsified silicone oil. The water-retaining agent is an acrylamide-acrylate copolymer cross-linked...

Embodiment 2

[0030] A waterproof slurry for construction, characterized in that the waterproof slurry includes waterproof emulsion and waterproof powder;

[0031]The waterproof powder includes the following raw materials by weight: 48 parts by weight of stone powder, 14 parts by weight of sand, 35 parts by weight of cement, 0.15 parts by weight of water reducing agent, 0.2 parts by weight of defoamer, 0.3 parts by weight of anti-cracking agent, adhesive 0.2 parts by weight of agent, 0.4 parts by weight of dispersant, and 0.1 parts by weight of auxiliary agent; said auxiliary agent includes gelling agent, water retaining agent, anti-alkali agent, retarder; wherein, said waterproof emulsion is anti-alkali waterproof emulsion. The alkali-resistant waterproof emulsion is an epoxy alkali-resistant primer emulsion. The water reducer is a naphthalene-based high-efficiency water reducer. The defoamer is emulsified silicone oil. The water-retaining agent is an acrylamide-acrylate copolymer cross-...

Embodiment 3

[0033] A waterproof slurry for construction, characterized in that the waterproof slurry includes waterproof emulsion and waterproof powder;

[0034] The waterproof powder includes the following raw materials by weight: 52 parts by weight of stone powder, 16 parts by weight of sand, 40 parts by weight of cement, 0.25 parts by weight of water reducing agent, 0.3 parts by weight of defoaming agent, 0.4 parts by weight of anti-cracking agent, adhesive 0.3 parts by weight of agent, 0.5 parts by weight of dispersant, 0.2 parts by weight of auxiliary agent; said auxiliary agent includes gelling agent, water retaining agent, anti-alkali agent, retarder, anti-mold agent; wherein, said waterproof emulsion is anti-alkali Waterproof lotion. The alkali-resistant waterproof emulsion is an epoxy alkali-resistant primer emulsion. The water reducer is an aliphatic high-efficiency water reducer. The defoamer is a high-carbon alcohol fatty acid ester compound. The water-retaining agent is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com