Graphite phase carbon nitride/graphene oxide heterojunction-epoxy acrylate composite material as well as preparation method and application thereof

A graphite phase carbon nitride, epoxy acrylate technology, applied in the coating and other directions, can solve the problems of low hardness, poor wear resistance, low mechanical and thermal properties, etc., achieve excellent hardness, enhance wear resistance, improve The effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

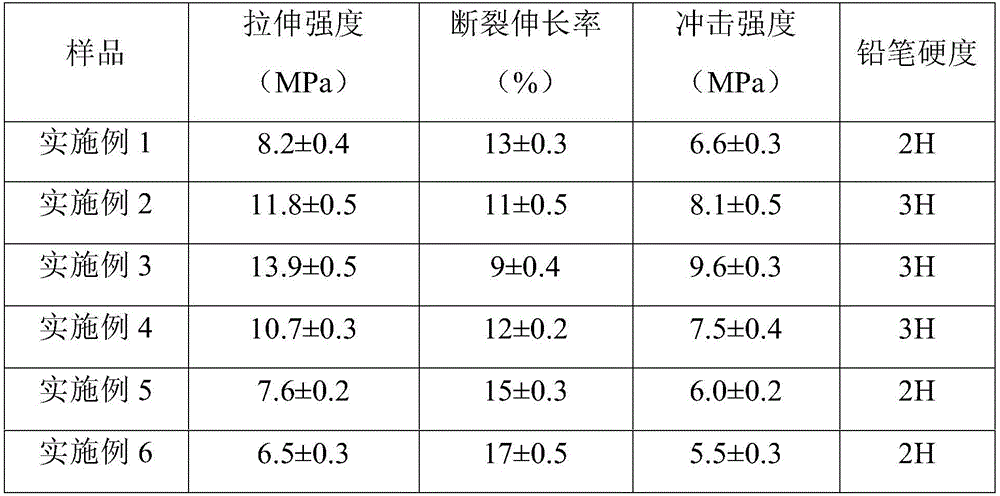

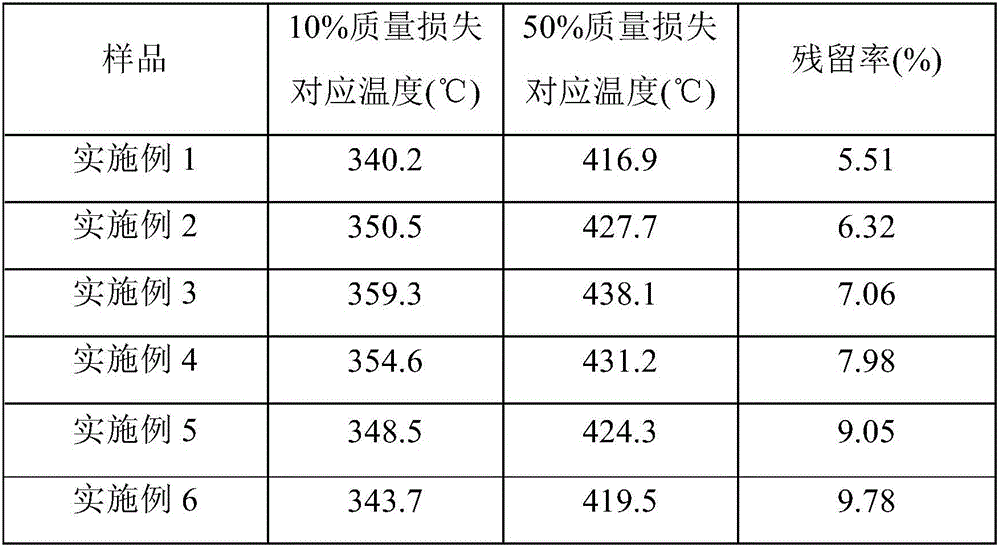

Examples

Embodiment 1

[0029] (1) Preparation of graphite phase carbon nitride: put 50g of melamine powder in a semi-closed alumina crucible, raise the temperature of the crucible to 230°C and keep it warm for 45min, continue to heat up to 330°C and keep it warm for 100min, and finally raise the temperature to 530°C and keep it warm 100min. Naturally cool to room temperature after the reaction, the obtained solid is vacuum-dried at 65°C for 24 hours, and the solid is sieved through a 300-mesh sieve to obtain graphite phase carbon nitride; the average particle size of the obtained graphite phase carbon nitride is 1-2 μm.

[0030] (2) Graphene oxide (purchased from Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, purity > 97wt.%, particle size 0.5-5 μm, thickness 0.55-2.0 nm) was mixed with deionized water to prepare 1 g / L solution. Take 300mL graphene oxide solution, add 5g graphitic carbon nitride, and ultrasonically react for 8h (400W). After the reaction was completed, the preci...

Embodiment 2

[0034](1) Preparation of graphite phase carbon nitride: put 55g of melamine powder in a semi-closed alumina crucible, raise the temperature of the crucible to 240°C and keep it warm for 60min, continue to heat up to 340°C and keep it warm for 120min, and finally raise the temperature to 540°C and keep it warm 120min. Naturally cool to room temperature after the reaction, the obtained solid is vacuum-dried at 60°C for 24 hours, and the solid is sieved through a 300-mesh sieve to obtain graphite phase carbon nitride; the average particle size of the obtained graphite phase carbon nitride is 1-2 μm.

[0035] (2) Graphene oxide (purchased from Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, purity > 97wt.%, particle size 0.5-5 μm, thickness 0.55-2.0 nm) was mixed with deionized water to prepare 1.2 g / L The solution. Take 350mL graphene oxide solution, add 6g graphitic carbon nitride, and ultrasonically react for 8.5h (400W). After the reaction, the precipitate ...

Embodiment 3

[0039] (1) Preparation of graphite phase carbon nitride: put 60g of melamine powder in a semi-closed alumina crucible, raise the temperature of the crucible to 250°C and keep it warm for 75min, continue to heat up to 350°C and keep it warm for 140min, and finally raise the temperature to 550°C and keep it warm 140min. Naturally cool to room temperature after the reaction, place the obtained solid at 80° C. for 36 hours in vacuum, and pass the solid through a 300-mesh sieve to obtain graphite phase carbon nitride; the average particle size of the obtained graphite phase carbon nitride is 1-2 μm.

[0040] (2) Graphene oxide (purchased from Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, purity > 97wt.%, particle size 0.5-5 μm, thickness 0.55-2.0 nm) was mixed with deionized water to prepare 1.4 g / L The solution. Take 380mL graphene oxide solution, add 7g graphitic carbon nitride, and ultrasonically react for 9h (400W). After the reaction was completed, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com