Preparation method of coating with super stain resistance and colorful effect and using method thereof

A super stain-resistant and colorful technology, applied in the field of building decoration materials, can solve the problems of non-dense paint film, inability to erase, limited scrub resistance, etc., and achieve the effect of high stain resistance, good waterproof, and dense coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

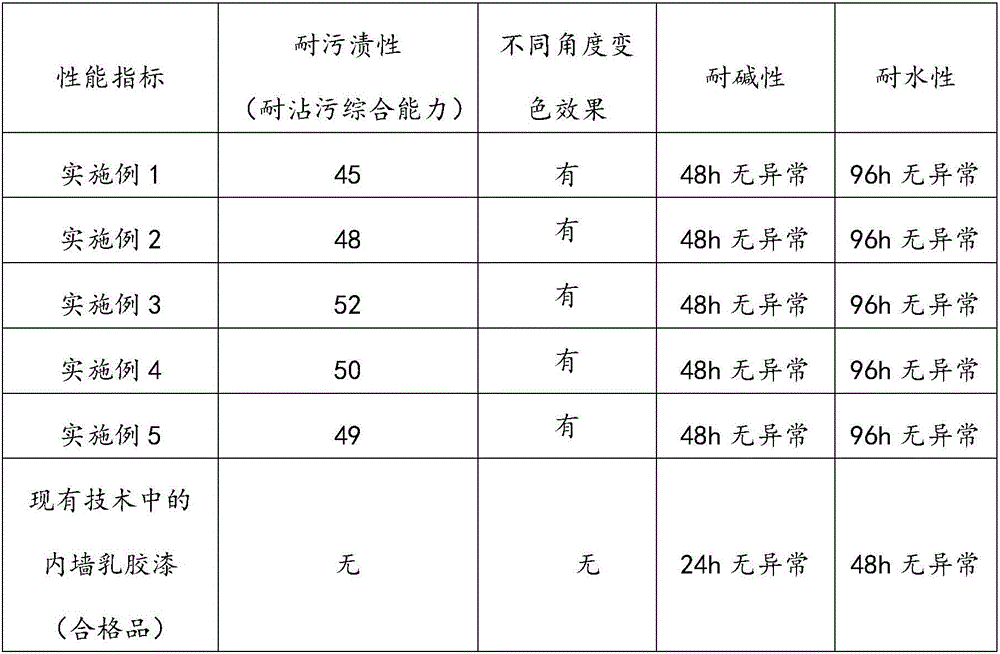

Examples

Embodiment 1

[0063] The coating of the present embodiment with super antifouling and colorful effects is made of the following raw materials in percentage by weight: 0.4% of cellulose, 1% of modified polycarboxylate, 0.2% of mineral oil defoamer, 2% of propylene glycol, 0.2% of isomeric alcohol ethoxy ether, 0.2% of multifunctional PH regulator, 4% of resorcinol bis-diphenyl phosphate, 38% of styrene-acrylic emulsion with a particle size of 0.09μm, and a modified particle size of 4-20nm 26% silica sol, 4% lauryl ester alcohol, 0.2% mixture of Cathones and BIT with a weight ratio of 1:1, 0.4% tetrachloroisophthalonitrile derivatives, and color-changing pearl powder with a particle size of 20-60mm 10%, non-ionic thickener 0.3% and water 13.1%.

[0064] The preparation method of the above-mentioned coating with super stain resistance and magic color effect comprises the following steps:

[0065] (1) take each raw material according to the percentage by weight of the above-mentioned coating w...

Embodiment 2

[0086] The coating with super anti-fouling and illusion effects in this embodiment is made of the following raw materials in weight percentage: 0.3% of cellulose, 0.8% of hydrophobic copolymer emulsion, 0.25% of modified silicone emulsion, 2.5% of polyol, super Branched polyether 0.3%, silicone PH regulator 0.16%, nitrogen-based flame retardant 4%, styrene-acrylic emulsion with a particle size of 0.09 μm 45%, modified silica sol with a particle size of 4-20nm 20%, ten 4% of six-carbon ester alcohol, 0.25% of the mixture of Cathones and BIT at a weight ratio of 1:1, 0.4% of the mixture of 2.6% OIT, 18% Diuron and 9.8% Carbendazim, and a particle size of 20- 60mm color-changing pearl powder 8%, non-ionic thickener 0.3%, hydrophobic alkali-swellable associative thickener 0.1% and water 13.64%.

[0087] The preparation method of the above-mentioned coating with super stain resistance and magic color effect comprises the following steps:

[0088] (1) take each raw material accordi...

Embodiment 3

[0097] The coating with super stain resistance and illusion effect of this embodiment is made of the following raw materials in weight percentage: 0.35% of cellulose, 1.5% of modified polycarboxylate, 0.3% of modified silicone emulsion, 2% of propylene glycol, 0.17% hyperbranched polyether, 0.18% multifunctional PH regulator, 4% resorcinol bis-diphenyl phosphate, 50% styrene-acrylic emulsion with a particle size of 0.09μm, and modified silicon with a particle size of 4-20nm Sol 10%, Cetyl Alcohol 4%, 0.25% of a mixture of Cathones and BIT at a weight ratio of 1:1, 0.4% of a mixture of 2.6% OIT, 18% Diuron and 9.8% Carbendazim 12% of pearl powder with a particle size of 20-60mm, 0.25% of non-ionic thickener and 14.6% of water.

[0098] The preparation method of the above-mentioned coating with super stain resistance and magic color effect comprises the following steps:

[0099] (1) take each raw material according to the percentage by weight of the above-mentioned coating with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com