Cleaning agent for water-based electronic industrial flux, as well as preparation method and using method thereof

A technology of electronic industry and flux, applied in the field of water-based electronic industry flux cleaning agent and its preparation, can solve the problems of cleaning device pollution and residue, human toxicity of cleaning agent, reducing the toxicity of cleaning agent, etc. Simple and convenient to use and simple mechanism of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

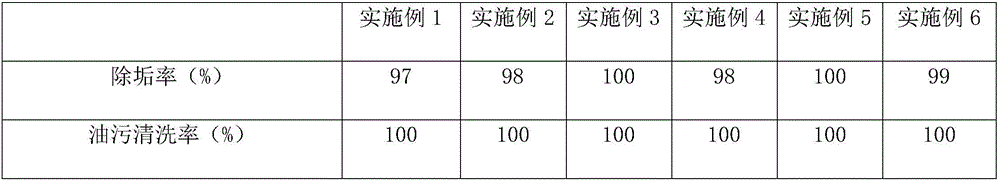

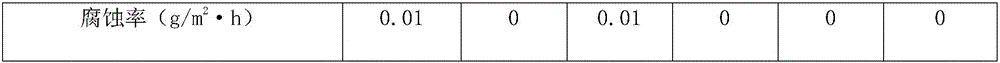

Examples

Embodiment 1

[0024] The components of the water-based electronic industry flux cleaning agent, in parts by weight, include 30 parts of high boiling point alcohol ether solvent, 10 parts of N-methyl-2-pyrrolidone, 2 parts of non-ionic surfactant, 5 parts of ethanol, water 100 parts, 0.5 part of polyether organosilicon nano defoamer, 0.1 part of water-soluble nano silica, 1 part of ethanolamine, among which, the components in the high-boiling alcohol ether solvent, by weight, include: diethylene glycol 1 part of diethyl ether, 1 part of diethylene glycol butyl ether, 0.5 part of diethylene glycol methyl ether, 0.8 part of dipropylene glycol butyl ether, components in non-ionic surfactants, by weight, including 0.1 part of FMEE, BEROL -226SA 0.1 part, PI-LQ-(AP) 0.1 part, TX-10 0.1 part, AEO-9 0.1 part, AEO-4 0.1 part.

[0025] The preparation method is as follows: add high boiling point alcohol ether solvent, N-methyl-2-pyrrolidone and ethanol to the reaction kettle at a speed of 500r / m, ice ba...

Embodiment 2

[0029] The components of the water-based electronic industry flux cleaning agent, in parts by weight, include 60 parts of high boiling point alcohol ether solvent, 20 parts of N-methyl-2-pyrrolidone, 5 parts of non-ionic surfactant, 10 parts of ethanol, water 5 parts, 5 parts of polyether organosilicon nano defoamer, 1 part of water-soluble nano silica, 3 parts of ethanolamine, among which, the components in the high boiling point alcohol ether solvent, by weight, include: diethylene glycol 3 parts of diethyl ether, 3 parts of diethylene glycol butyl ether, 2 parts of diethylene glycol methyl ether, 3 parts of dipropylene glycol butyl ether, the components of nonionic surfactants, by weight, include 0.5 part of FMEE, 0.5 part of BEROL-226SA, 0.5 part of PI-LQ-(AP), 0.5 part of TX-10, 0.5 part of AEO-9, 0.5 part of AEO-4.

[0030] The preparation method is as follows: add high boiling point alcohol ether solvent, N-methyl-2-pyrrolidone and ethanol to the reaction kettle at a rotat...

Embodiment 3

[0034] The components of the water-based electronic industry flux cleaning agent, in parts by weight, include 50 parts of high boiling point alcohol ether solvent, 15 parts of N-methyl-2-pyrrolidone, 3 parts of non-ionic surfactant, 8 parts of ethanol, water 50 parts, 2.5 parts of polyether organosilicon nano defoamer, 0.5 parts of water-soluble nano silica, 2.5 parts of ethanolamine, among which, the components in the high boiling point alcohol ether solvent, by weight, include: diethylene glycol 2 parts of diethyl ether, 2.5 parts of diethylene glycol butyl ether, 1.5 parts of diethylene glycol methyl ether, 1.2 parts of dipropylene glycol butyl ether, the components of non-ionic surfactants, by weight, include 0.35 parts of FMEE, 0.2 part of BEROL-226SA, 0.3 part of PI-LQ-(AP), 0.4 part of TX-10, 0.2 part of AEO-9, 0.3 part of AEO-4.

[0035] The preparation method is: at 800r / m, add high boiling point alcohol ether solvent, N-methyl-2-pyrrolidone and ethanol to the reaction k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com