Neutral and nearly-neutral water oxidation catalytic electrodes in transition metal salt nano arrays

A transition metal salt and nano-array technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of low catalytic activity, high voltage of hydrogen production system, etc., and achieve the effect of reducing energy consumption and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Evenly disperse 1.45g of nickel nitrate and 1.40g of hexamethylenetetramine in 36ml of distilled water, and then transfer the above mixture into a 50ml polytetrafluoroethylene liner.

[0021] Step 2: Put the carbon cloth into the polytetrafluoroethylene lining in step 1, seal the lining with a stainless steel mold, and place it in a constant temperature drying oven at 100°C for 10 hours.

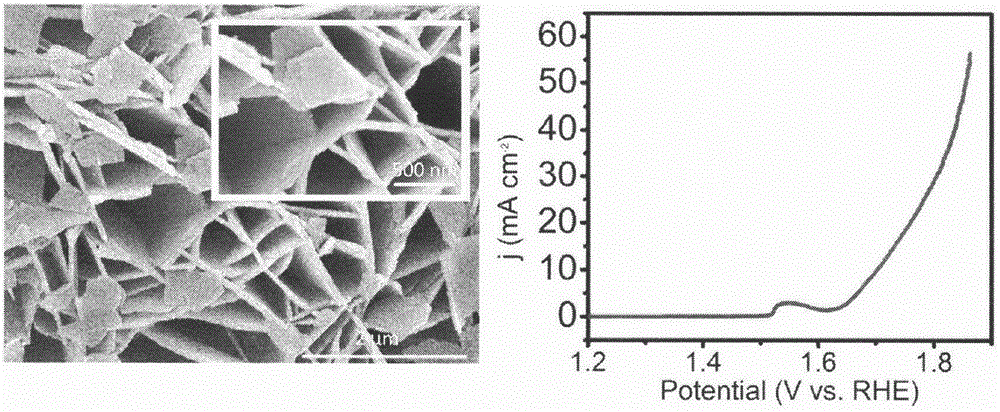

[0022] Step 3: After the reaction, cool down the reactor to room temperature, then take out the carbon cloth and wash it with distilled water and absolute ethanol. Dry in vacuum at 40°C for 24h to obtain Ni(OH) 2 Nanosheet arrays.

[0023] Step 4: Put the precursor prepared in Step 3 in a tube furnace, and react at 300° C. for 2 hours in an argon atmosphere to obtain a NiO nanosheet array.

[0024] Step 5: Use the NiO nanosheet array as the working electrode of the electrochemical workstation, the silver / silver chloride electrode, and the platinum electrode as the reference ...

Embodiment 2

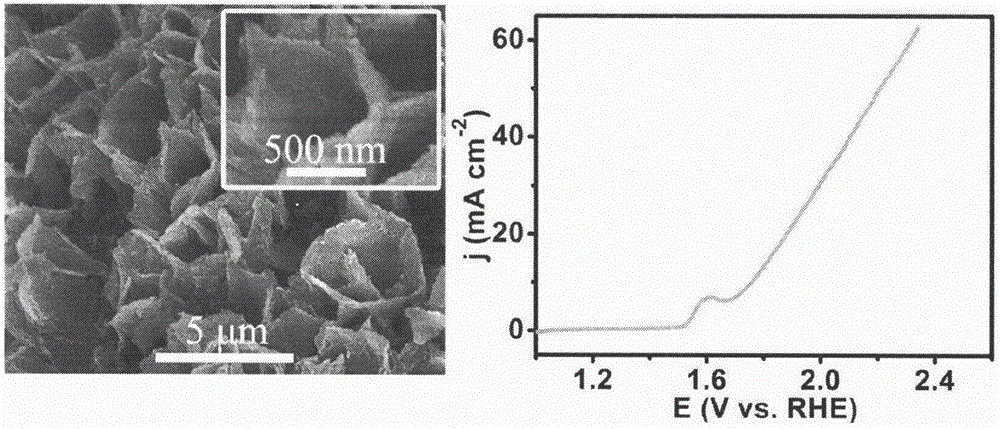

[0027] Step 1: Dissolve 0.87g of cobalt nitrate hexahydrate, 0.29g of ammonium fluoride, and 0.9g of urea in 50ml of distilled water, and then transfer the mixture to 50ml of polytetrafluoroethylene lining.

[0028] Step 2: Put the titanium mesh into the polytetrafluoroethylene lining in step 1, seal the lining into a stainless steel mold, and place it in a constant temperature drying oven at 120° C. for 6 hours.

[0029] Step 3: After the reaction is completed, cool the reaction vessel to room temperature, take out the titanium mesh, wash it, and dry it in a vacuum drying oven at 40° C. for 24 hours.

[0030] Step 4: Place the dried sample in Step 3 and 0.5 g of sodium hydrogen hypophosphite in a tube furnace, and react at 300° C. for 2 hours in an argon atmosphere to obtain a CoP nanowire array.

[0031] Step 5: Use the CoP nanosheet array as the working electrode of the electrochemical workstation, the silver / silver chloride electrode, and the platinum electrode as the refe...

Embodiment 3

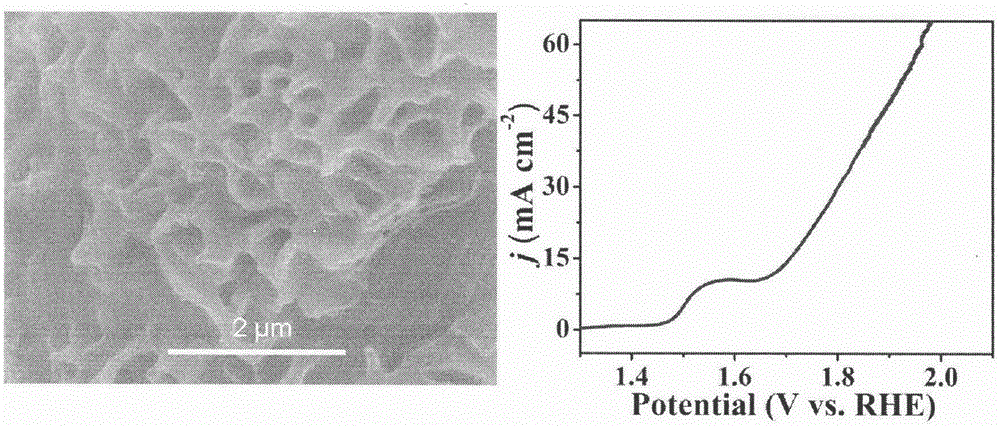

[0034] Step 1: Evenly disperse 1.42g of nickel nitrate and 1.38g of hexamethylenetetramine in 38ml of distilled water, and then transfer the above mixed liquid to a polytetrafluoroethylene liner. Step 2: Put the carbon cloth into the polytetrafluoroethylene lining in step 1, seal the lining with a stainless steel mold, and place it in a constant temperature drying oven at 100°C for 10 hours.

[0035] Step 3: After the reaction, cool down the reactor to room temperature, then take out the carbon cloth and wash it with distilled water and absolute ethanol. Dry in vacuum at 60°C for 24h to obtain Ni(OH) 2 Nanosheet arrays.

[0036] Step 4: Put the precursor prepared in Step 3 and 1g of sodium hypophosphite in a tube furnace, and react at 300°C for 2h in an argon atmosphere to obtain Ni 2 p.

[0037] Step Five: Use Ni 2 The P nanosheet array is used as the working electrode of the electrochemical workstation, and the silver / silver chloride electrode and the platinum electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com