Bismuth ferrite/nickel hydroxide secondary alkali battery and preparation method therefor

A nickel hydroxide, alkaline battery technology, applied in the field of electrochemical energy storage, can solve the problem of less research on electrochemical performance, and achieve the effects of superior rate performance, large electric capacity, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 5mmol of bismuth acetate and 5mmol of iron acetate, dissolve them in 100ml of distilled water, raise the temperature to 90°C, and add 20ml of 5mol / L tartaric acid solution dropwise while stirring. After the dropwise addition, keep the temperature and continue stirring for 3h. After drying and grinding, the precursor powder is obtained; the precursor powder is placed in a tube furnace, and the O 2 with N 2 In the mixed atmosphere (O 2 Gas and N 2 The volume percentages of gas are respectively 25% and 75%), the temperature is raised to 500° C. for heat treatment for 5 h, and then the furnace is cooled to room temperature, and the resulting heat treatment product is washed with distilled water and ethanol several times respectively, and solid-liquid separation is carried out. Vacuum drying at a temperature of 80°C to a constant weight yields bismuth ferrite material.

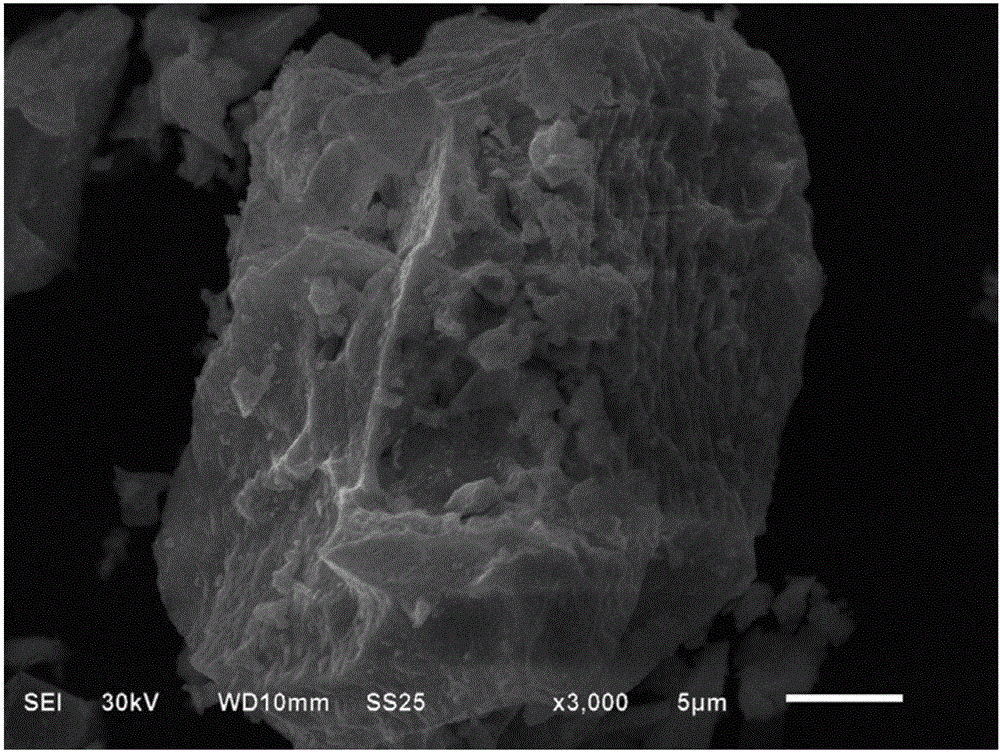

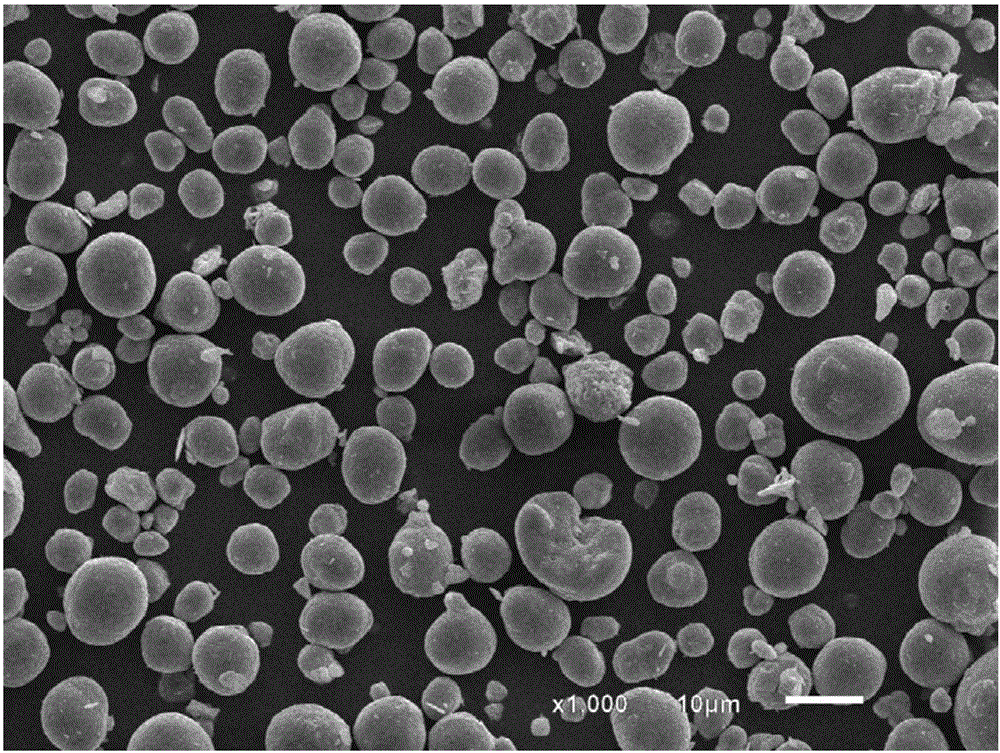

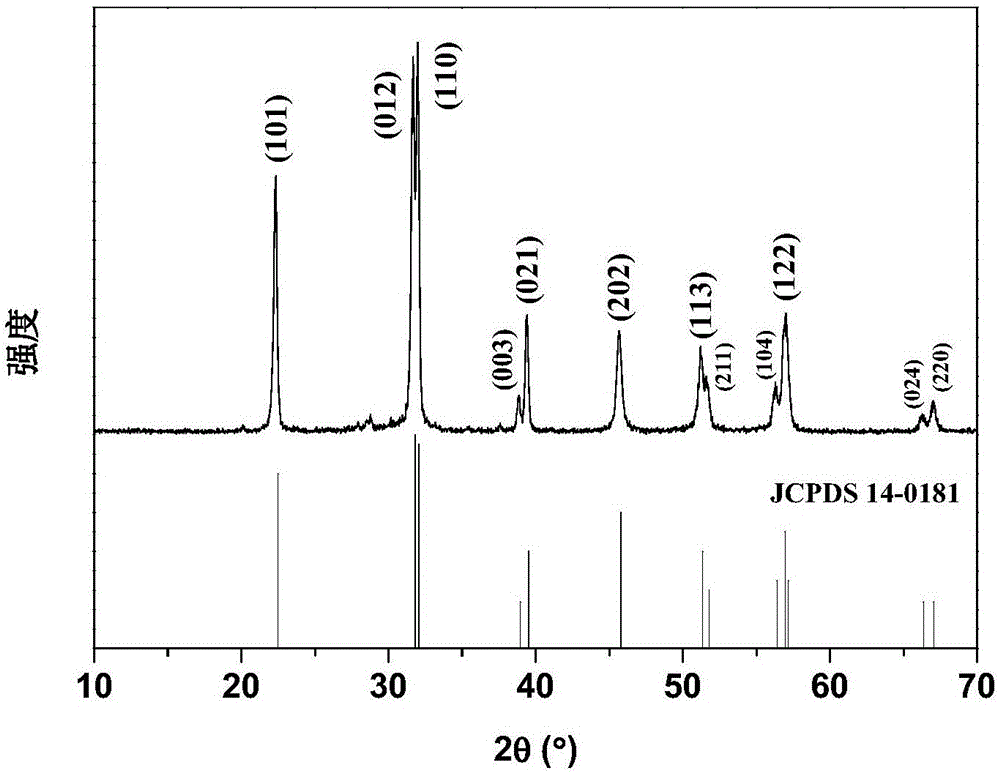

[0044] (2) Adopt the JEOLJEM-3010 type scanning electron microscope to test the bismuth ferr...

Embodiment 2

[0053] (1) Weigh 2mmol of bismuth oxide and 2mmol of iron oxide, disperse them in 50ml of ethanol, raise the temperature to 70°C, and add 20ml of 4mol / L tartrate ethanol solution dropwise while stirring. After the dropwise addition, keep the temperature and stir for 5h. After drying and grinding, the precursor powder was obtained; the precursor powder was placed in a muffle furnace, heated to 600°C in the air environment for heat treatment for 6 hours, and then cooled to room temperature with the furnace, and the heat-treated product was washed with distilled water and ethanol for several times, and suction filtration, and vacuum-dry the solid product at 120° C. to constant weight to obtain a bismuth ferrite material.

[0054] (2) the preparation of nickel hydroxide electrode and bismuth ferrite electrode is with the step (4) in embodiment 1

[0055] (3) Put the prepared nickel hydroxide electrode sheet / diaphragm / bismuth ferrite electrode sheet into a special battery mold in t...

Embodiment 3

[0058] (1) Weigh 5mmol of bismuth nitrate and 4.5mmol of ferric nitrate, dissolve them in 100ml of distilled water, raise the temperature to 100°C, add 50ml of 4mol / L citric acid solution dropwise while stirring, after the dropwise addition, keep the temperature and continue to stir for reaction After 2 hours, the precursor powder was obtained by drying and grinding, and the precursor powder was placed in a tube furnace, and the flow rate was 100ml / min. 2 with CO 2 In the mixed atmosphere (O 2 Gas and CO 2 The volume percentages of gas are respectively 35% and 65%), heated up to 600°C for heat treatment for 6h, and then cooled to room temperature with the furnace, the heat-treated product was washed with distilled water and ethanol several times, and suction filtered, and the solid product was heated at 90°C Dry under vacuum until constant weight to obtain bismuth ferrite material.

[0059] (2) Preparation of bismuth ferrite electrode and nickel hydroxide electrode

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com