Hybrid modified composite material with high-conductivity and high-toughness structure and preparation method of hybrid modified composite material

A composite material, high conductivity technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the application that is not suitable for industrial batches, the difficulty of effectively transferring to the interlayer of composite materials, and the difficulty of meeting aviation requirements Lightning protection, electrostatic shielding and other issues of composite materials, to achieve the effect of meeting lightning protection and electrostatic shielding, improving conductivity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

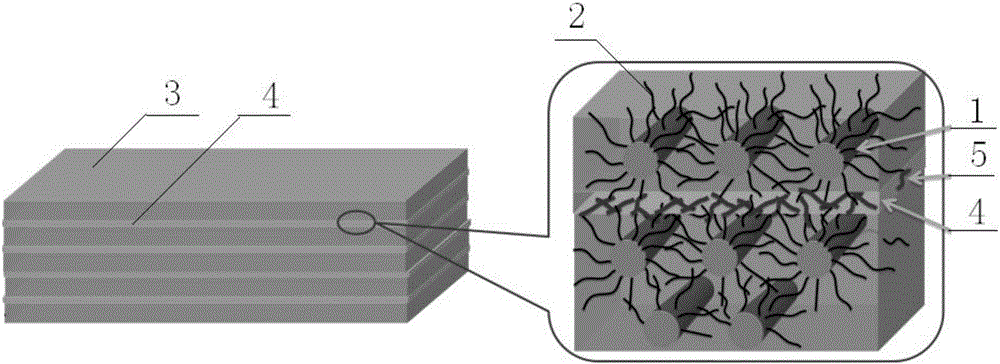

[0021] The preparation method of the hybrid modified high-conductivity and high-toughening structural composite material as described above is characterized in that: the preparation steps are as follows:

[0022] 1. Determine the number of layers of the hybrid modified high-conductivity and high-toughening structural composite material and the material types of the nano-hybrid modified continuous fiber reinforced layer 3 and the nano-organic porous toughened membrane 4;

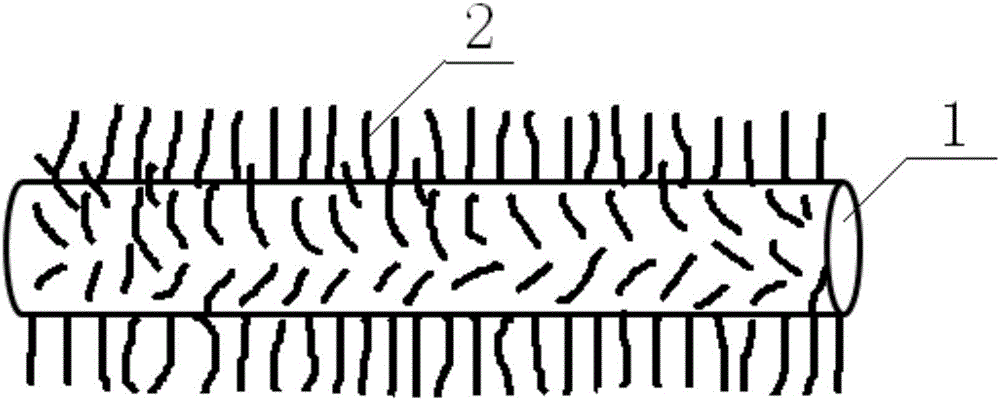

[0023] 2. Preparation of continuous fibers or fabrics modified by nano-hybridization: Graft carbon nanotubes on the surface of continuous fibers by chemical vapor deposition, and the catalyst precursor used is the organometallic compound ferrocene dissolved in the organic solvent xylene , its concentration is 0.05g / ml, in inert gas Ar, reducing gas hydrogen H 2 and acetylene gas C 2 h 2 In the atmosphere, at a temperature of 600 ° C ~ 700 ° C, the growth time is 1 min ~ 60 min, where Ar, H 2 with C 2 h 2...

Embodiment 1

[0031] 1. Determine the material type of the hybrid modified high-conductivity and high-toughening structural composite material. In the nano-hybrid modified continuous fiber reinforcement layer 3, QY9916 epoxy resin is used as the matrix and T700 grade carbon fiber with a diameter of 7 μm is used as the continuous fiber reinforcement Body and carbon nanotubes are modified materials, and the conductive nanomaterial in the nano-organic porous toughened film 4 is a silver nanowire with a length of about 50 μm and an average diameter of 70 nm. The organic film is a nylon non-woven fabric with a thickness of 500 nm. According to the thickness of the composite material sample, it is determined that the number of layers of the continuous fiber reinforced layer 3 is 24 layers, and the number of layers of the nano-organic porous toughened membrane 4 is 23 layers.

[0032] 2. Preparation of nano-hybrid modified continuous fibers: In-situ growth of carbon nanotubes with a grafted mass fr...

Embodiment 2

[0039] 1. Determine the material type of the hybrid modified high-conductivity and high-toughening structural composite material. In the nano-hybrid modified continuous fiber reinforced layer 3, QY9916 epoxy resin is used as the matrix and T800 grade carbon fiber with a diameter of 7 μm is used as continuous fiber reinforcement Body and carbon nanotubes are modified materials, and the conductive nanomaterials in the nano organic porous toughened film 4 are silver nanowires with a length of about 50 μm and an average diameter of 120 nm and multi-walled carbon nanotubes with a purity greater than 95%, organic thin films Use PEK-C.

[0040] 2. Preparation of continuous fibers or fabrics modified by nano-hybridization: In-situ growth of carbon nanotubes with a grafted mass fraction of 1 wt% on the surface of continuous carbon fibers by chemical vapor deposition. The diameter of the carbon nanotubes is 20nm and the length is 5 μm. The catalyst precursor used is an organometallic co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com