Self-repairing type ultraviolet light cured anti-doodling resin and preparation method thereof

An anti-graffiti resin, ultraviolet light technology, applied in anti-fouling/underwater coatings, coatings, polyurea/polyurethane coatings, etc. Fast curing speed, increased dirt resistance, low cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

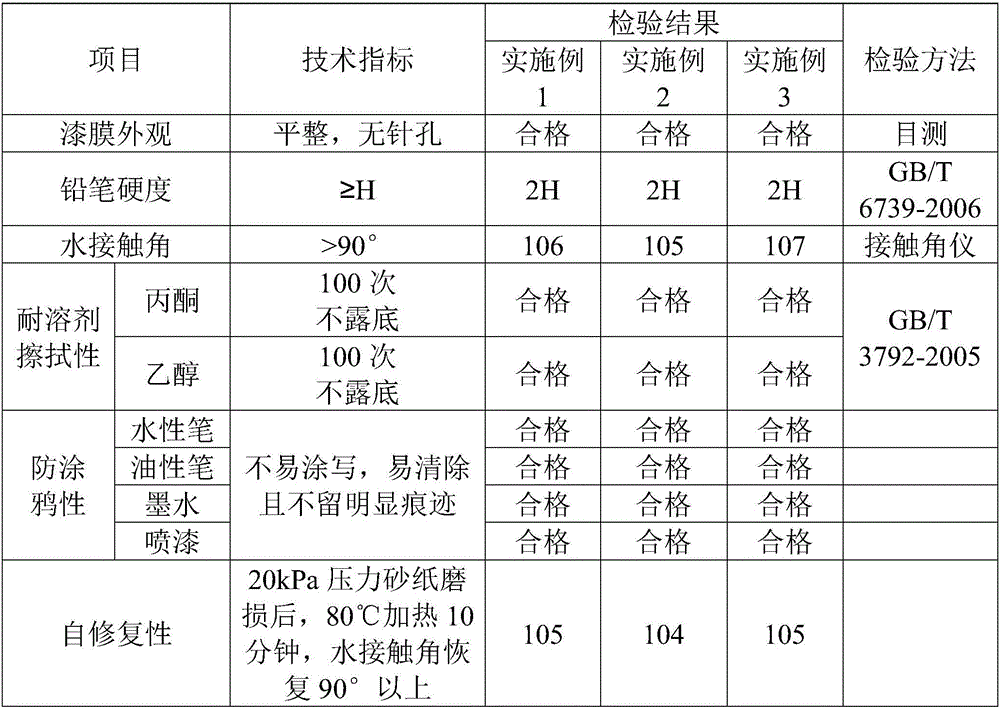

Examples

Embodiment 1

[0025] (1) 5 parts by mass of diphenylmethane diisocyanate, 3 parts by mass of polyethylene glycol (molecular weight: 600g / mol), 4 parts by mass of hydroxyl-terminated silicone oil (molecular weight: 1000g / mol) and 0.5 parts by mass of stearyl ester Isocyanate chain extender, dissolved in 30 parts by mass of tetrahydrofuran to obtain a uniform mixed solution and added 0.08 parts by mass of dibutyltin dilaurate, stirred and reacted at 60°C for 4 hours, slowly cooled to 40°C, and then 5 parts by mass of pentaerythritol tri Acrylic ester, 0.05 parts by mass of polymerization inhibitor hydroquinone and appropriate amount of tetrahydrofuran were mixed uniformly and added therein, stirred and reacted at 40° C. for 3 hours, and tetrahydrofuran was distilled off under reduced pressure to obtain a UV-curable polyurethane resin.

[0026] (2) The method for preparing the anti-graffiti resin is: 20 parts by mass of UV-curable polyurethane resin, 8 parts by mass of trimethylolpropane triacr...

Embodiment 2

[0028] (1) 6 parts by mass of isophorone diisocyanate, 5 parts by mass of polypropylene glycol (molecular weight: 1000g / mol), 3 parts by mass of hydroxyl-terminated silicone oil (molecular weight: 600g / mol) and 0.4 parts by mass of dodecyl ester isocyanate Chain extender, dissolved in 25 parts by mass of acetone to obtain a uniform mixed solution and added 0.05 parts by mass of dibutyltin dilaurate, stirred and reacted at 60°C for 4 hours, slowly cooled to 40°C, and then 8 parts by mass of methacrylic acid Hydroxypropyl ester, 0.06 parts by mass of polymerization inhibitor hydroquinone and appropriate amount of acetone were mixed uniformly and added therein, stirred and reacted at 40° C. for 3 hours, and the acetone was distilled off under reduced pressure to obtain a UV-curable polyurethane resin.

[0029] (2) The method for preparing the anti-graffiti resin is: with 30 parts by mass of UV-curable polyurethane resin, 12 parts by mass of isobornyl acrylate dispersed titanium di...

Embodiment 3

[0031] (1) 8 parts by mass of hexamethylene diisocyanate, 5 parts by mass of polycarbonate diol (molecular weight: 400g / mol), 6 parts by mass of hydroxyl-terminated silicone oil (molecular weight: 2000g / mol) and 0.3 parts by mass of octadecane Base ester isocyanate chain extender, dissolved in 40 parts by mass of tetrahydrofuran to obtain a uniform mixed solution and added 0.06 parts by mass of dibutyltin dilaurate, stirred and reacted at 60 ° C for 4 hours, slowly cooled to 40 ° C, and then 7 parts by mass of dibutyltin dilaurate Dipentaerythritol pentaacrylate, 0.06 parts by mass of polymerization inhibitor hydroquinone and appropriate amount of tetrahydrofuran were mixed uniformly and added thereto, stirred and reacted at 40° C. for 3 hours, and tetrahydrofuran was distilled off under reduced pressure to obtain a UV-curable polyurethane resin.

[0032] (2) The method for preparing the anti-graffiti resin is: 30 parts by mass of UV-curable polyurethane resin, 10 parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com