Adhesive for bamboo wound compound pipe and preparation method of adhesive

A technology for adhesives and composite pipes, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems that have not been mentioned about bamboo winding composite pipes, and achieve Improve the ultraviolet light absorption activity, increase the service life, and improve the effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The raw material for the preparation of the graphite phase carbon nitride is one or more of dicyandiamide, urea and cyanuric acid.

[0062]The present invention uses graphite phase carbon nitride as a reinforcing agent. Due to its unique electronic energy band structure, graphite phase carbon nitride can absorb ultraviolet light, significantly improve the aging resistance of the adhesive, and increase the use of the adhesive. Lifespan; In addition, graphite phase carbon nitride has antibacterial activity under light conditions, and it is added to the adhesive for the bonding of bamboo materials, which can effectively prevent bamboo materials from mildew, insects and decay, and further improve bamboo. Service life of wound composite pipe.

[0063] The imidazole ionic liquid is chlorinated 1-butyl-3-methylimidazolium ionic liquid, chlorinated 1-allyl-3-methylimidazolium ionic liquid, chlorinated 1-(2-hydroxyethyl)- 3-methylimidazole ionic liquid, 1-butyl-3-methylimidazol...

Embodiment 1

[0086] Prepare the adhesive of adhesive embodiment 1 according to the following process

[0087] The preparation of step one amino resin

[0088] a. Add 620g of formaldehyde into a sealable container, stir, and add 216g of urea;

[0089] b, adjust the pH value to 8.0 with a NaOH solution with a mass concentration of 20%, add 63g melamine and 8.5g polyvinyl alcohol;

[0090] c, the temperature is raised to 70°C, and the pH value is adjusted to 7 with a NaOH solution with a mass concentration of 20%;

[0091] d. Continue to heat up to 80°C, and keep it warm for 30 minutes;

[0092] e. Use a phosphoric acid solution with a mass concentration of 10% to adjust the pH value to 5.0, add the acid slowly, and the dripping time is 20 minutes; adjusting the system to acidity can promote the condensation reaction and improve the adhesion of the system;

[0093] f. Use NaOH solution with a mass concentration of 20% to adjust the pH value to 8.5, add 7g melamine and 72g urea again, and r...

Embodiment 2

[0105] Prepare the adhesive of adhesive embodiment 2 according to the following process

[0106] The preparation of step one amino resin

[0107] The preparation of amino resin is with embodiment 1;

[0108] Step two preparation of the main agent

[0109] a. Take 1.8 g of graphite phase carbon nitride and 3 g of 1-allyl-3-methylimidazolium chloride ionic liquid, add 10 g of deionized water, stir, and ultrasonically disperse to mix evenly to obtain graphite phase carbon nitride Dispersions;

[0110] B, get above-mentioned graphite phase carbon nitride dispersion liquid, the amino resin that makes in 52g comparative example, the deionized water of 14g, the chloride 1-allyl-3-methylimidazolium ionic liquid of 3g and 0.4g ammoniacal liquor , mix it evenly, stir it mechanically for 3 hours, and then filter it with an 80-mesh filter cloth to obtain the main ingredient;

[0111] Step 3 Preparation of Adhesive

[0112] Stir 50 g of the main agent prepared in step 2 and 7 g of cur...

PUM

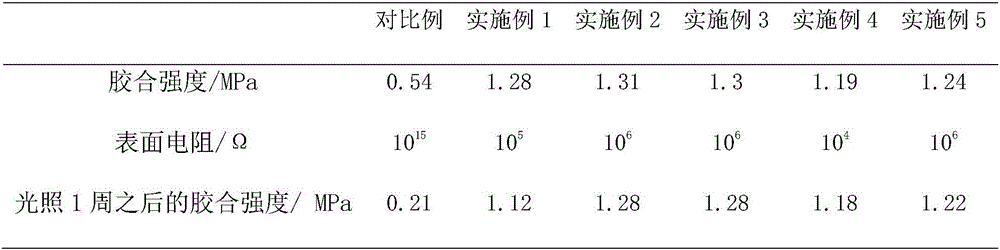

| Property | Measurement | Unit |

|---|---|---|

| Bonding strength | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com