A kind of preparation method of spherical micronano grade calcium carbonate

A micro-nano, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve problems such as shortage, achieve high degree of spherification, concentrated particle size distribution, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

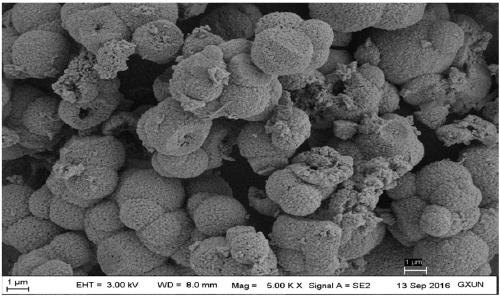

Embodiment 1

[0039] A preparation method for spherical micro-nano calcium carbonate, comprising the following steps:

[0040] (1) Dissolve ammonium carbonate in deionized water to prepare NH 4 + The concentration is 1.2mol / L, add 0.1g of the additive potassium hexacyanoferrate, stir with magnetic stirring at 300r / min to form solution A, the concentration of the additive in solution A is 1mg / L;

[0041] (2) Calcium chloride was dissolved in deionized water to prepare a solution with a concentration of 1 mol / L to form solution B.

[0042] (3) Use a peristaltic pump to drop solution A into solution B at a rate of 2661 ul / min, then continue to stir in solution B at 300 r / min, and react for 2 hours after the addition is complete. During the reaction, the reaction temperature was controlled at 30° C. with a cryostat.

[0043] (4) After the reaction is complete, the product obtained in step (3) is washed with water, suction filtered, and dried, wherein the drying temperature is 110°C. The dry...

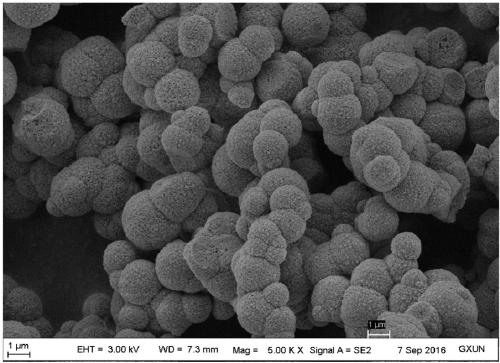

Embodiment 2

[0047] A preparation method for spherical micro-nano calcium carbonate, comprising the following steps:

[0048] (1) Dissolve ammonium carbonate in deionized water to prepare NH 4 + The concentration of the solution is 2mol / L, adding 0.15g of sodium pyrophosphate as an additive, and stirring with a magnetic stirrer at 30r / min to form a solution A, and the concentration of the additive in solution A is 1.5mg / L.

[0049] (2) Calcium chloride is dissolved in deionized water to prepare Ca2+ A solution with a concentration of 1 mol / L forms solution B.

[0050] (3) Add solution A dropwise to solution B at a rate of 2664ul / min with a peristaltic pump, then continue to stir in solution B at 300r / min, and react for 1.5 hours after the addition is complete. During the reaction, the reaction temperature was controlled at 30° C. with a cryostat.

[0051] (4) After the reaction is complete, the product obtained in step (3) is washed with water, suction filtered, and dried, wherein the d...

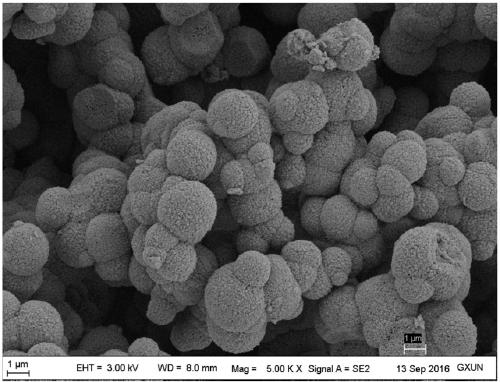

Embodiment 3

[0055] A preparation method for spherical micro-nano calcium carbonate, comprising the following steps:

[0056] (1) Dissolve ammonium carbonate in deionized water to prepare NH 4 + The concentration of the solution is 1.5 mol / L, add 0.15 g of sodium trimetaphosphate as an additive, and stir at 300 r / min with a magnetic stirrer to form a solution A. The additive concentration in solution A is 1.5mg / L.

[0057] (2) Calcium chloride is dissolved in deionized water to prepare Ca 2+ A solution with a concentration of 1.5 mol / L forms solution B.

[0058] (3) Add solution A dropwise to solution B at a rate of 2668ul / min with a peristaltic pump, then continue to stir in solution B at 300r / min, and react for 2 hours after the addition is complete. During the reaction, the reaction temperature was controlled at 30° C. with a cryostat.

[0059] (4) After the reaction is complete, the product obtained in step (3) is washed with water, suction filtered, and dried, wherein the drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com