Organic-inorganic hybrid core-shell particle as well as preparation method and application thereof

A core-shell particle and inorganic technology, applied in the field of core-shell particles and their preparation, can solve the problems of poor dispersion of core-shell particles, increase in mechanical properties such as strength, increase in epoxy resin viscosity, etc., and achieve sufficient toughening and strengthening effect. , the effect of improving tensile properties, toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 26g of diethylenetriamine to a 250mL three-necked flask, place it in an ice-water bath, add methyl acrylate-methanol solution (26g of methyl acrylate dissolved in 50mL of methanol) dropwise, react for 24 hours after the dropwise addition, add 1g SiO 2 Nanoparticles, 0.5g triblock copolymer P123, 0.5g triamine, stirred gently for 12h, removed methanol at 90°C using a rotary evaporator, then moved to an oil bath and heated to 150°C, 2 Stir the reaction for 4 hours under protection, wash the product three times with THF, and centrifuge for 5 minutes (5000rpm) to obtain a pale white powder, put it in a vacuum oven and dry at 80°C for 12 hours to obtain HBP-SiO 2 Organic-inorganic hybrid core-shell particles.

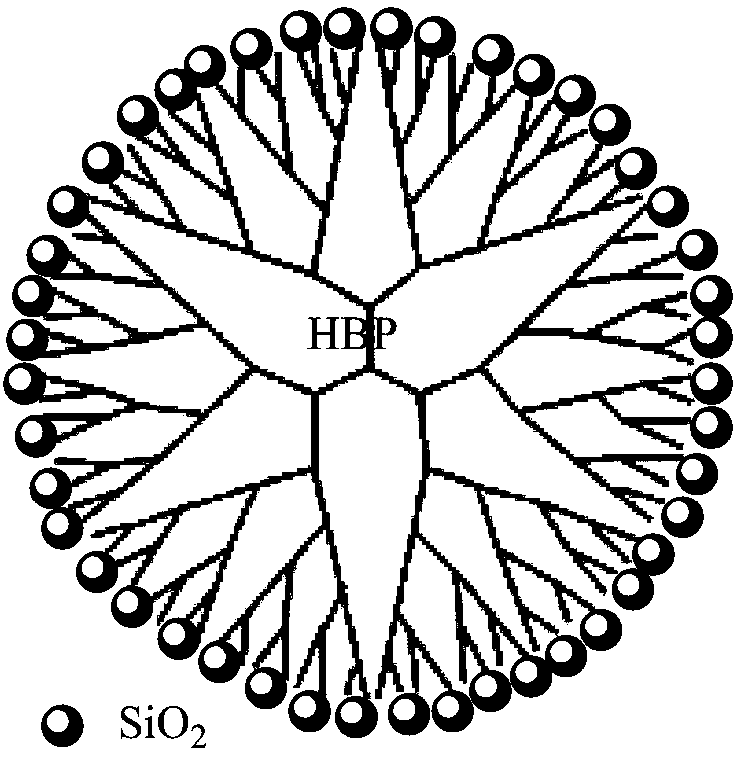

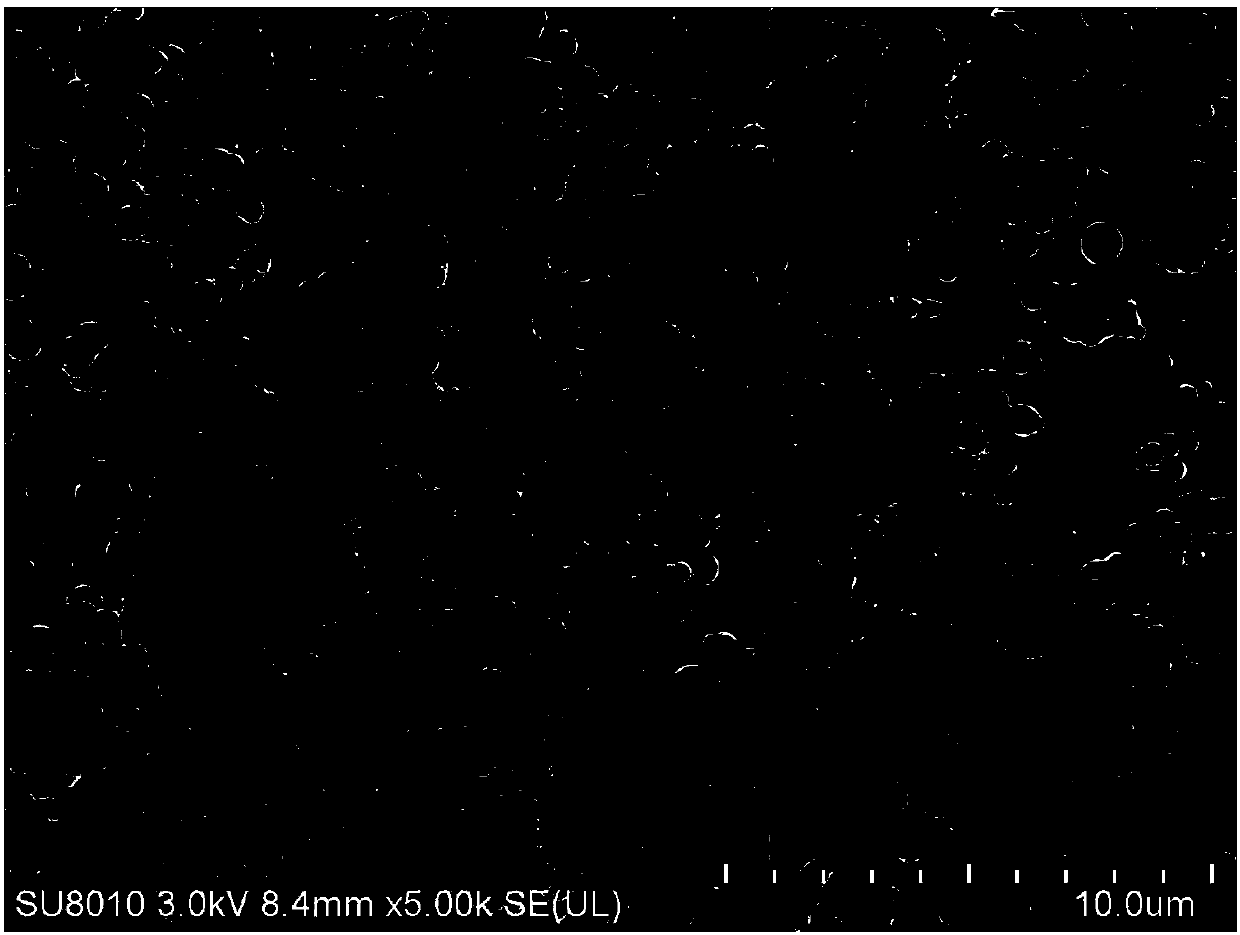

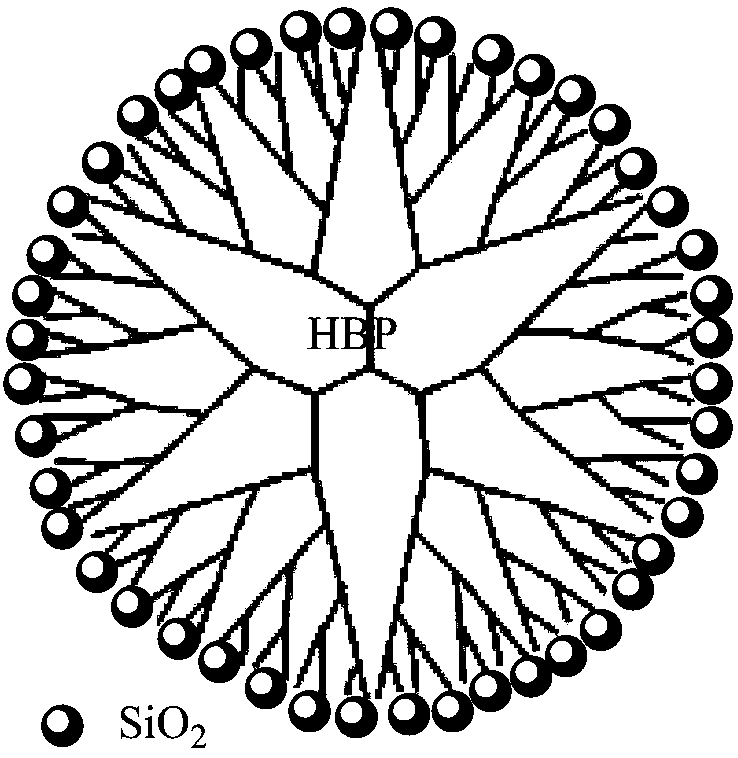

[0028] figure 2 For the HBP-SiO prepared in this embodiment 2 SEM images of organic-inorganic hybrid core-shell particles, by figure 2 It can be seen that the HBP-SiO 2 The diameter of organic-inorganic hybrid core-shell particles is 40-100nm, and the shell...

Embodiment 2

[0031] Add 26g of diethylenetriamine to a 250mL three-necked flask, place it in an ice-water bath, add methyl acrylate-methanol solution (26g of methyl acrylate dissolved in 50mL of methanol) dropwise, react for 24 hours after the dropwise addition, add 1g SiO 2Nanoparticles, 0.5g tri-block copolymer P123, 0.5g triamine, stirred gently for 12h, removed methanol at 90°C using a rotary evaporator, then moved to an oil bath and heated to 150°C, in N 2 Stir the reaction for 4 hours under protection, wash the product three times with THF, and centrifuge for 5 minutes (5000rpm) to obtain a light white powder, put it in a vacuum oven and dry at 80°C for 12 hours to obtain HBP-SiO 2 Organic-inorganic hybrid core-shell particles.

[0032] Take 2g of the above HBP-SiO 2 Add organic-inorganic hybrid core-shell particles to a homogeneous mixture of 100g of bisphenol A diglycidyl ether epoxy resin and 30g of diaminodiphenylmethane, and stir evenly. The curing condition is 150°C / 2h+200°C...

Embodiment 3

[0034] Add 27.3g of diethylenetriamine to a 250mL three-necked flask, place it in an ice-water bath, add methyl acrylate-methanol solution (26g of methyl acrylate dissolved in 50mL of methanol) dropwise, and react for 24 hours after the dropwise addition is completed. Add 2g SiO 2 Nanoparticles, 1g triblock copolymer P123, 0.5g triamine, stirred gently for 12h, used a rotary evaporator to remove methanol at 90°C, then moved to an oil bath and heated to 150°C, 2 Stir the reaction for 4 hours under protection, wash the product three times with THF, and centrifuge for 5 minutes (5000rpm) to obtain a light white powder, put it in a vacuum oven and dry at 80°C for 12 hours to obtain HBP-SiO 2 Organic-inorganic hybrid core-shell particles.

[0035] Take 4g of the above HBP-SiO 2 Organic-inorganic hybrid core-shell particles were added to a homogeneous mixture of 100g bisphenol A diglycidyl ether epoxy resin and 35g 3,3'-diethyl-4,4'diaminodiphenylmethane, and stirred evenly. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com