Application of methacrylatoethyl dodecyl dimethyl ammonium bromide in disperse silicon dioxide as well as composite material and preparation method of composite material

A technology of methacryloyloxyethyldodecyldimethylammonium bromide and methyl methacrylate, which is applied in the dispersion of methacryloyloxyethyldodecyldimethylammonium bromide. The application of silicon oxide and its composite materials and preparation fields can solve the problems of negative impact on the macroscopic properties of composite materials, long production cycle, complex operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

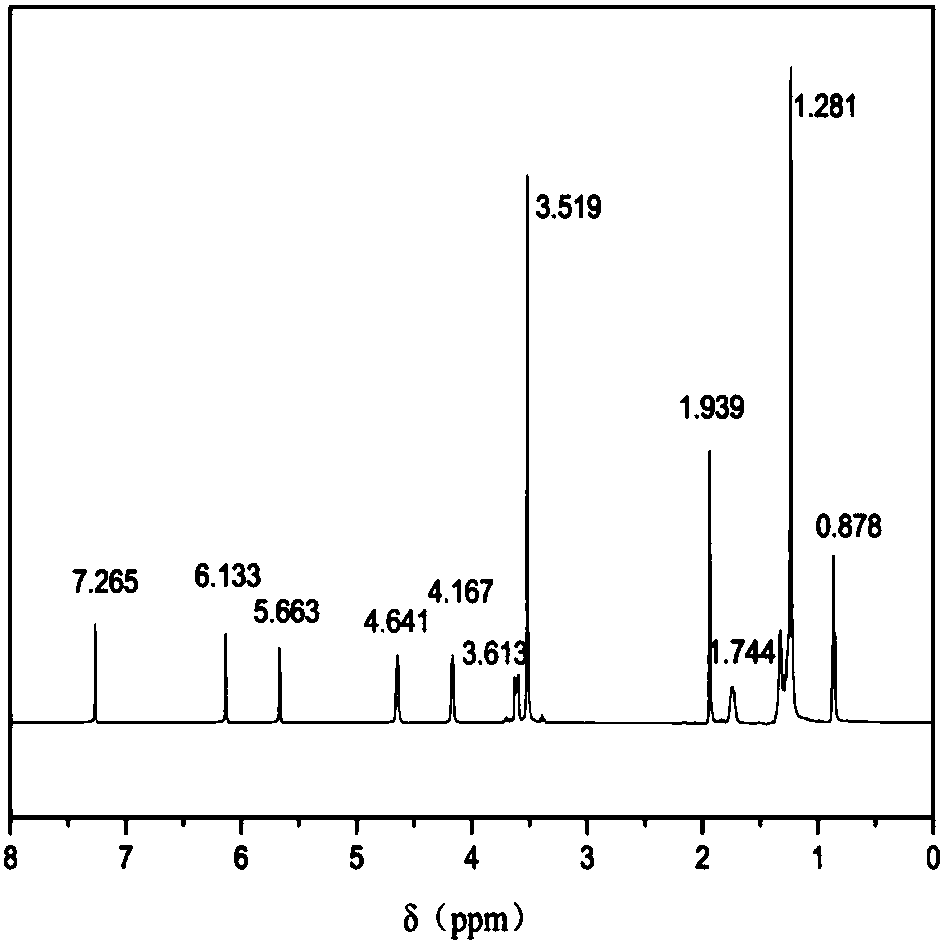

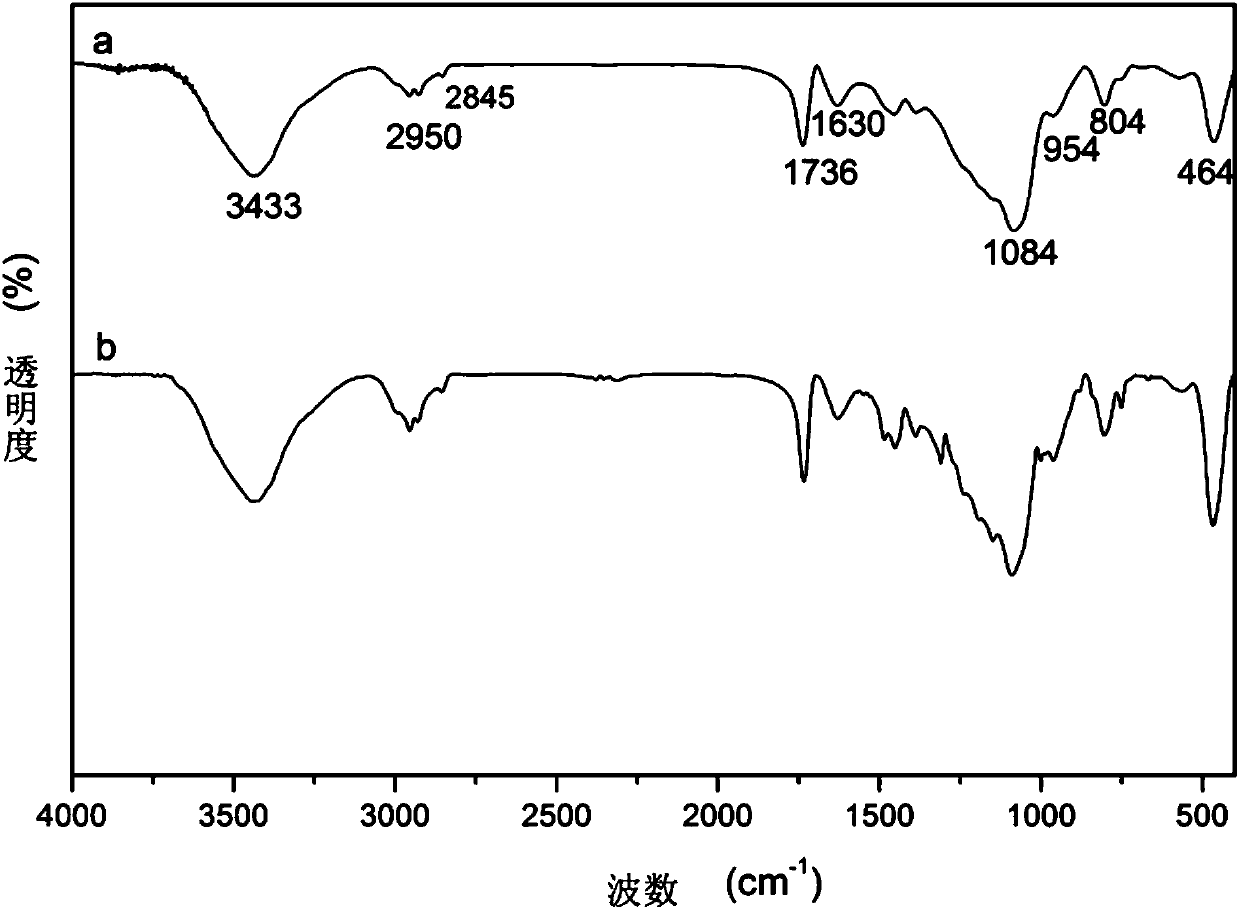

[0035] (1) 98wt% MMA monomer and 1wt% MEDDAB are added in the there-necked flask; 2wt% SiO is added in 240mL deionized water 2 , 1wt% MEDDAB, ultrasonically disperse the mixture, add 2.5wt% hydroxyethyl cellulose (HEC), then add it into a three-necked flask, and stir at a low speed of 400r / min. Access to N 2 After protecting for 40 minutes, raise the temperature to 75°C, and keep an inert atmosphere, add 0.8wt% initiator BPO to initiate polymerization, and adjust the speed to 700r / min; stop heating after 6 hours of reaction, and continue stirring; after 30min, reduce the speed to 400r / min min; after 15 min, the reaction ended. The reaction system was cooled and filtered, the filtered product was repeatedly washed with deionized water, and vacuum-dried at 60 °C to a constant weight to obtain P(MMA-co-MEDDAB) / SiO 2 nanocomposites;

[0036] (2) P(MMA-co-MEDDAB) / SiO 2 The copolymerization product (powder) is thermocompressed with a thermocompression molding machine. The hot p...

Embodiment 2

[0038] (1) 96wt% MMA monomer and 2wt% MEDDAB are added in the there-necked flask; 4wt% SiO is added in 240mL deionized water 2 , 2wt% MEDDAB, ultrasonically disperse the mixture, add 3.0wt% basic magnesium carbonate, then add it into a three-necked flask, and stir at a low speed of 400r / min. After 60 minutes of argon protection, the temperature was raised to 72 ° C, and the inert atmosphere was continuously maintained, and 1.5 wt % initiator azobisisobutyronitrile (AIBN) was added to initiate polymerization, and the rotation speed was adjusted to 700 r / min; after 5 hours of reaction, the heating was stopped. Continue to stir; after 40 minutes, reduce the rotation speed to 400r / min; after 10 minutes, the reaction ends. The reaction system was cooled and filtered, the filtered product was repeatedly washed with deionized water, and dried in vacuum at 50 °C to a constant weight to obtain P(MMA-co-MEDDAB) / SiO 2 nanocomposites;

[0039] (2) P(MMA-co-MEDDAB) / SiO 2 The copolymeriz...

Embodiment 3

[0041] (1) 97wt% MMA monomer and 1.5wt% MEDDAB are added in the there-necked flask; 6wt% SiO is added in 240mL deionized water 2 , 1.5wt% MEDDAB, ultrasonically disperse the mixture, add 3.0wt% hydroxycalcium phosphate (HAP), then add it into the three-necked flask, and stir at a low speed of 400r / min. After passing through helium protection for 30 minutes, the temperature was raised to 78 ° C, and the inert atmosphere was continuously maintained, and 1.0 wt % initiator azobisisoheptanonitrile (ABVN) was added to initiate polymerization, and the rotation speed was adjusted to 700 r / min; after 10 hours of reaction, the heating was stopped. Continue stirring; after 15 minutes, reduce the rotation speed to 400r / min; after 5 minutes, the reaction ends. The reaction system was cooled and filtered, the filtered product was repeatedly washed with deionized water, and dried in vacuum at 70 °C to a constant weight to obtain P(MMA-co-MEDDAB) / SiO 2 nanocomposites;

[0042] (2) P(MMA-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com