Saline soil roadbed filler and method for improving roadbed

A technology of subgrade filling and saline soil, which is applied in the field of geotechnical engineering, can solve problems affecting the formation and stability of CSH, high toxicity or danger, and weak salt corrosion resistance, so as to achieve good application prospects, shorten the maintenance cycle, and improve The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0048] This preparation example is used to illustrate the method of artificially preparing saline soil.

[0049] Sodium sulfate was added to the soil particles (collected from the suburbs of Bin County, Harbin), and after grinding and sieving, artificially prepared saline soils with a salt content of 1%, 3%, and 5% of their mass fractions were obtained, wherein , soil particles with a particle size of 0.25-0.5mm account for 20% of the total soil particle weight, soil particles with a particle size of 0.5-1mm account for 20% of the total soil particle weight, and particles with a particle size of 1-2mm account for the total soil particle weight 60% of.

preparation example 2

[0051] This preparation example is used to illustrate the preparation method of the microbial preparation.

[0052] Inoculate the culture medium (formulation: beef extract 5g / L, peptone 15g / L, sodium chloride 5g / L), cultured at 30°C for 48h to obtain a density of 1×10 9 CFU / mL of bacterial liquid.

Embodiment 1

[0054] This example is used to illustrate the saline soil roadbed filler provided by the present invention and its preparation method.

[0055] Take by weighing 100g saline soil with a salt content of 1% by weight obtained by Preparation Example 1, 5g anhydrous calcium chloride powder, 8g urea (purchased from Shandong Luxi Chemical Company, the same below), 10mL obtained by Preparation Example 2 and 1 g of sodium bicarbonate were placed in a mixer and stirred at room temperature (25° C.) for 0.5 h to obtain saline soil roadbed filler A1 (pH value was 8, water content was 25% by weight).

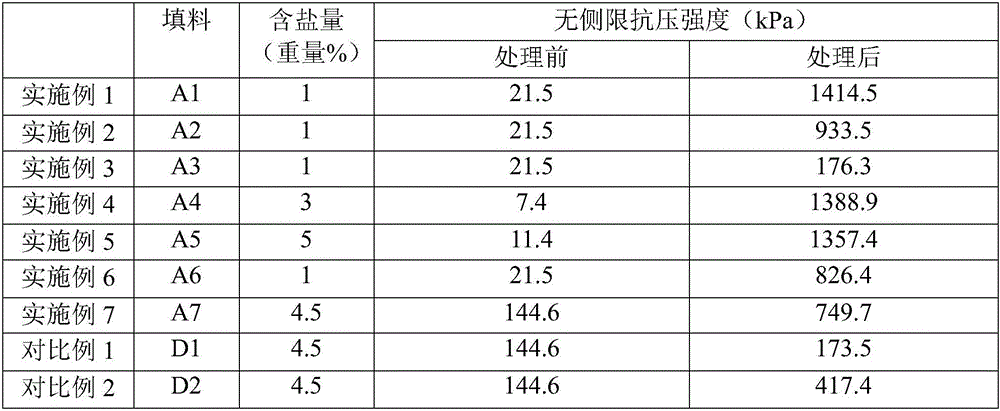

[0056] The results of the unconfined compressive strength of the saline soil roadbed filler A1 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com