Silicon-base cathode material for lithium ion battery and preparation method of silicon-base cathode material

A silicon-based negative electrode material, lithium-ion battery technology, applied in battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of serious volume expansion effect, decreased battery cycle stability, high volume expansion rate, etc., and achieve excellent structure Stability, improved stability, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

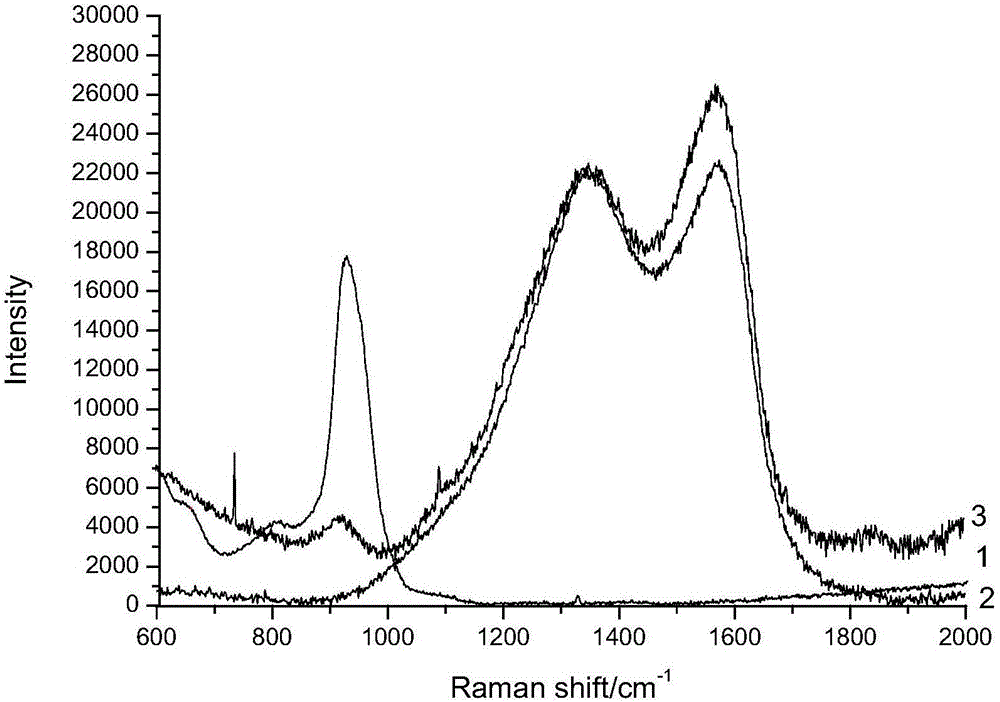

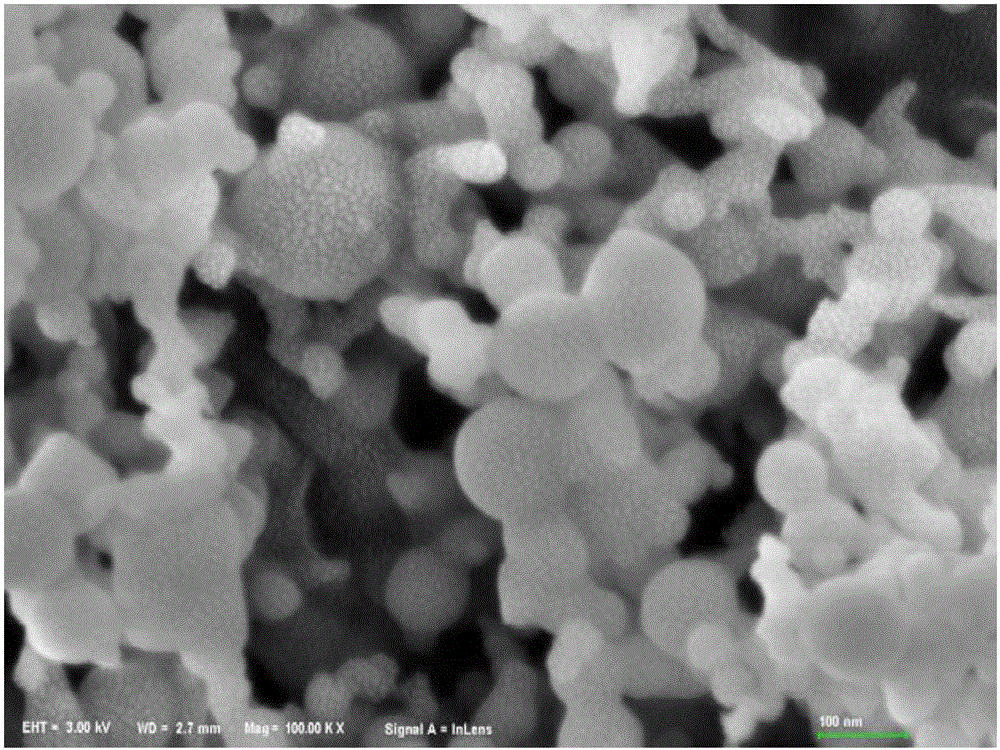

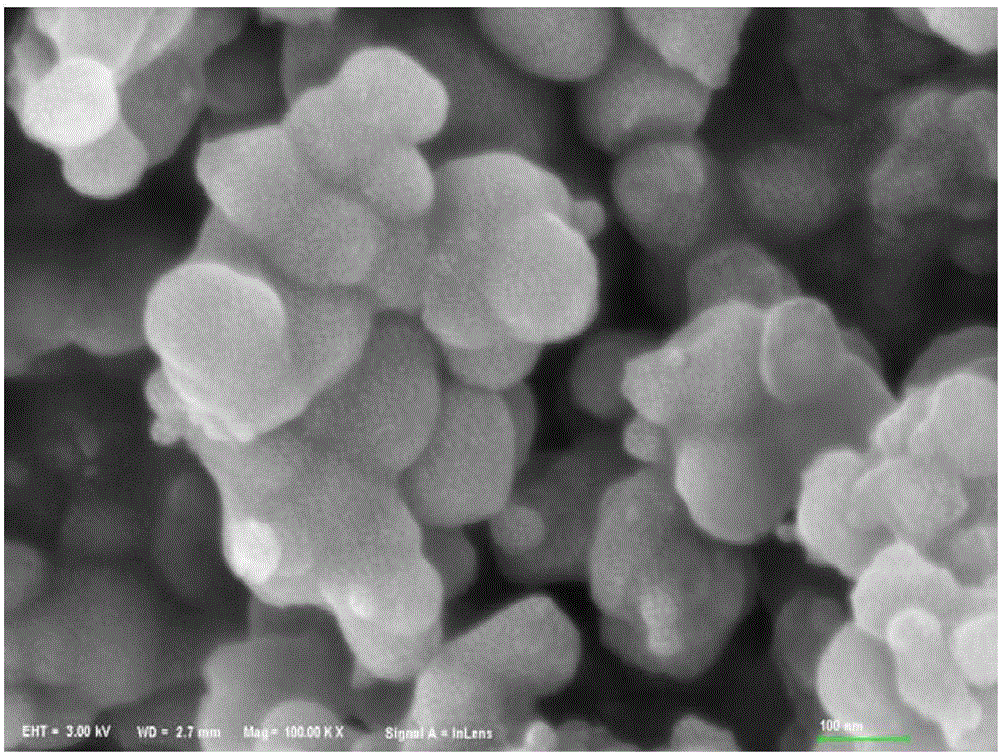

Image

Examples

Embodiment 1

[0038] A silicon-based negative electrode material for a lithium ion battery, the preparation steps of which are as follows:

[0039] 1) Mix 0.1g of nano-silicon powder (100-120nm in particle size) with 90mL of concentrated hydrochloric acid with a concentration of 37wt%, and magnetically stir it at room temperature for 1h, then suction filter and wash until the filtrate is neutral and the particles The zeta potential of the surface is negative, and the surface-treated nano-silicon powder is obtained;

[0040]2) Add 0.1211g of tris to a beaker containing 100mL of deionized water to prepare a Tris solution, add 0.2g of dopamine monomer to the obtained Tris solution under nitrogen, and stir fully to obtain dopamine Solution, test the pH value of the solution with pH test paper, and adjust the pH value of the solution to 8.5 with 37wt% hydrochloric acid;

[0041] 3) Pour the dopamine mixed solution obtained in step 2) into the constant pressure titration funnel quickly, isolate ...

Embodiment 2

[0051] A method similar to that of Example 1 is used to prepare silicon-based negative electrode materials for lithium-ion batteries. The difference is that step 1) processes the nano silicon powder with concentrated hydrochloric acid for 0.5h, and step 2) Tris solution is made of 0.6g trimethylol It is prepared by mixing methylaminomethane with 100mL deionized water.

[0052] After testing, the performance of the silicon-based negative electrode material prepared in this example is close to that of the silicon-based negative electrode material obtained in Example 1.

Embodiment 3

[0054] A method similar to that of Example 1 was used to prepare a silicon-based negative electrode material for lithium-ion batteries, except that the volume of concentrated hydrochloric acid used in step 1) was 60 mL.

[0055] The silicon-based negative electrode powder obtained above is prepared as a lithium-ion battery, and the specific steps are as follows:

[0056] a) Dissolve CMC with deionized water first, wherein CMC is 3.5 mg, it is advisable to add deionized water to make the solution reach a suitable viscosity, and stir magnetically for 10 hours until a homogeneous solution is obtained;

[0057] b) 35 mg of the silicon-based active material prepared in this embodiment and 5.25 mg of acetylene black were mixed and ground for half an hour, and poured into the homogeneous solution obtained in the previous step, so that the mass ratio of the silicon-based negative electrode material, acetylene black and CMC was: 80:12:8, add 3 drops of 2.5wt% Tween20 solution dropwise,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com