Raphnus sativus compound vegetable powder and preparation method thereof

A technology of rouge radish and vegetable powder, which is applied in the field of rouge radish compound vegetable powder and its preparation, can solve problems such as the limited range of resource utilization of rouge radish, unbalanced nutrition of a single radish vegetable powder, and difficulty in powdering radish vegetables. Achieve the effects of improving rough skin, improving night blindness, and improving the function of central nervous tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] One, the preparation technological process of rouge radish compound vegetable powder of the present invention is as a whole:

[0041] Raw material selection→cleaning→cutting→pulping→grinding→blending→homogenizing→drying→milling→finished product

[0042] 1. Selection: Mature with no serious physical damage, no damage from diseases and insect pests, and no rot.

[0043] 2. Cleaning: Clean the selected radishes and sweet potatoes, drain and set aside.

[0044] 3. Slicing: Cut rouge radish and sweet potato into 1cm 3 left and right blocks.

[0045] 4. Beating: Pour an appropriate amount of water into the cooking machine, put the cut rouge radish pieces and sweet potato pieces into a food blender for beating. Repeat beating 2-3 times, 120s each time.

[0046] 5. Grinding: Add the compound slurry of rouge radish and sweet potato to the colloid mill for grinding and crushing.

[0047] 6. Blending: Add maltodextrin, citric acid, β-cyclodextrin and white granulated sugar to...

Embodiment 1

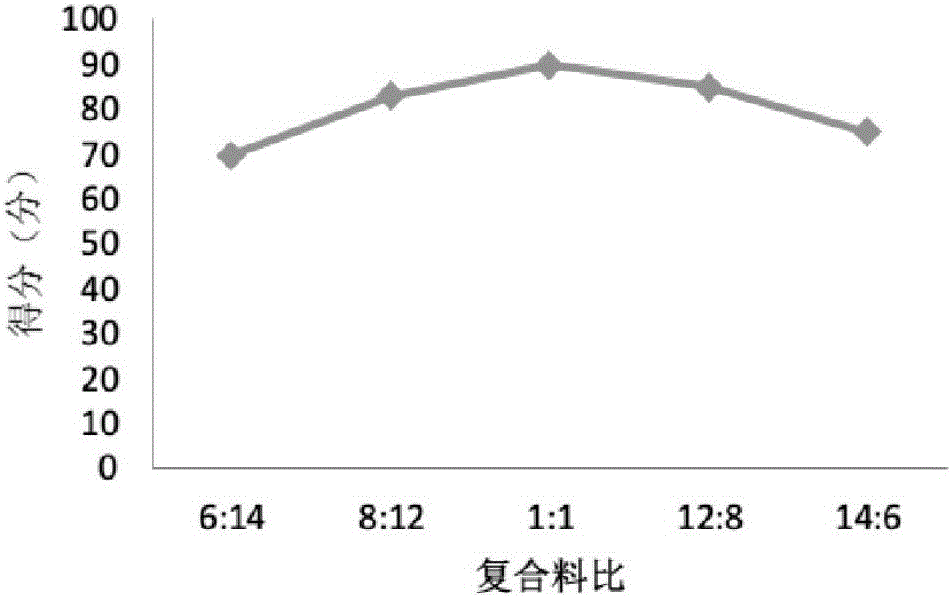

[0064] The determination of embodiment 1 composite material ratio

[0065] Experimental settings The addition of β-cyclodextrin is 0.5% of the total mass of rouge radish and sweet potato, the addition of white sugar is 40%, the addition of maltodextrin is 2%, and the addition of citric acid is 0.15%. The mass ratios of rouge radish to sweet potato are 6:14, 8:12, 1:1, 12:8, 6:14, respectively. During the preparation, wash the rouge radish and sweet potato, cut them into pieces, add water to make a slurry, the ratio of the total mass of the rouge radish and sweet potato to water is 1:0.4, and repeat the beating for 2 to 3 times for 120 seconds each time. The compound slurry of radish and sweet potato is added into the colloid mill for grinding and crushing, and the number of passes through the colloid mill is controlled to 2 times, and the above-mentioned amount of maltodextrin, citric acid, and β-cyclic Blend dextrin and white sugar, homogenize the blended slurry for 2 minute...

Embodiment 2

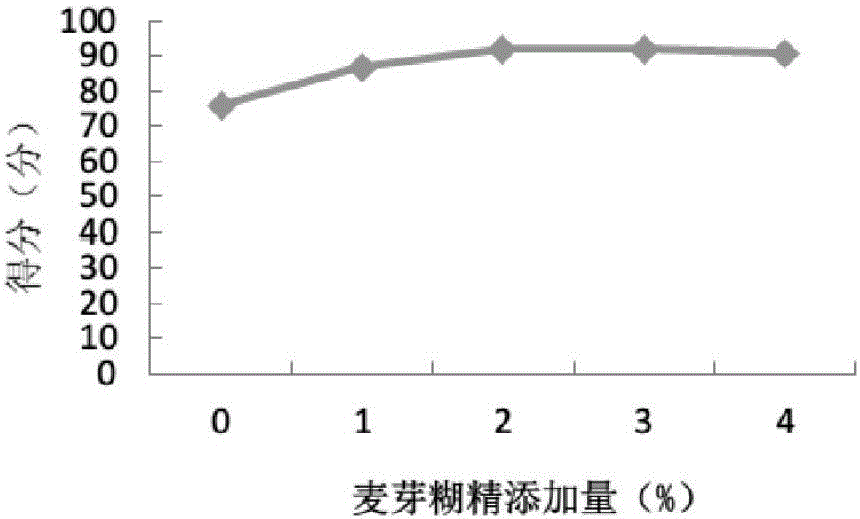

[0067] The determination of the amount of maltodextrin added in embodiment 2

[0068] In the experiment, the added amount of white sugar was fixed at 40%, the compound material ratio was 1:1, the added amount of β-cyclodextrin was 0.5%, and the added amount of citric acid was 0.15%. The addition amount (%) of essence is: 0, 1, 2, 3, 4, other conditions in the preparation process are the same as embodiment 1.

[0069] This example mainly investigates the influence of the change of the amount of maltodextrin added on the sensory quality of compound vegetable powder. The sensory score is as follows: figure 2 shown by figure 2 It can be seen that the sensory quality of compound vegetable powder increases with the increase of maltodextrin addition, but when the addition exceeds 2%, the score tends to be stable, and when it reaches 4%, the score decreases slightly. The addition of maltodextrin can make the vegetable powder loose, not easy to agglomerate, dissolve quickly, have g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com