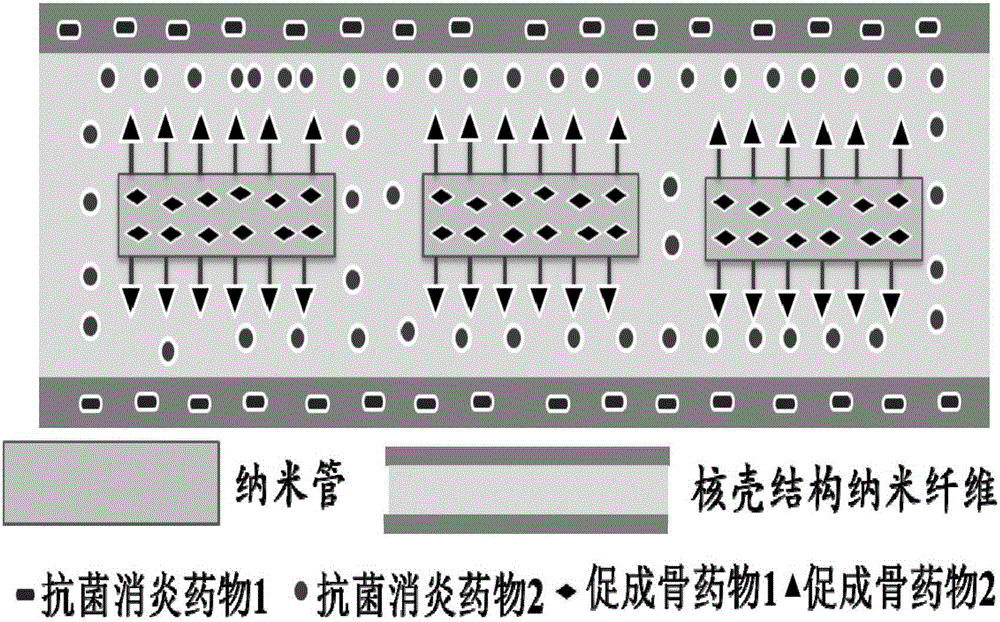

Preparation method of bone restoration material containing multiple drug-loaded slow release systems

A technology for bone repair and sustained release, which is used in medical science, prosthesis, tissue regeneration, etc., and can solve problems such as non-infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

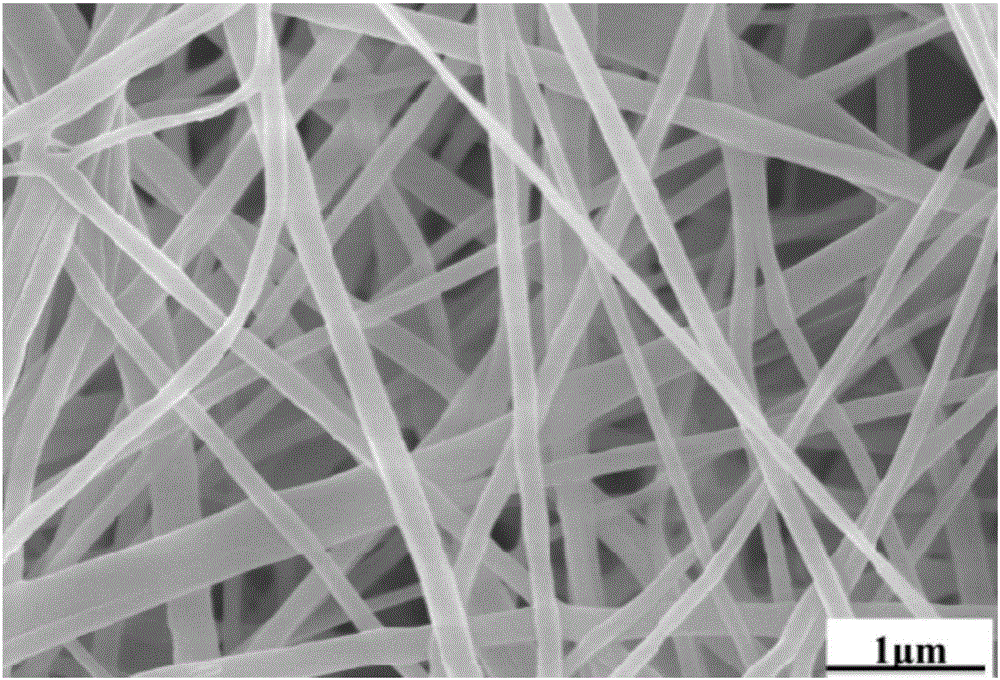

Method used

Image

Examples

Embodiment 1

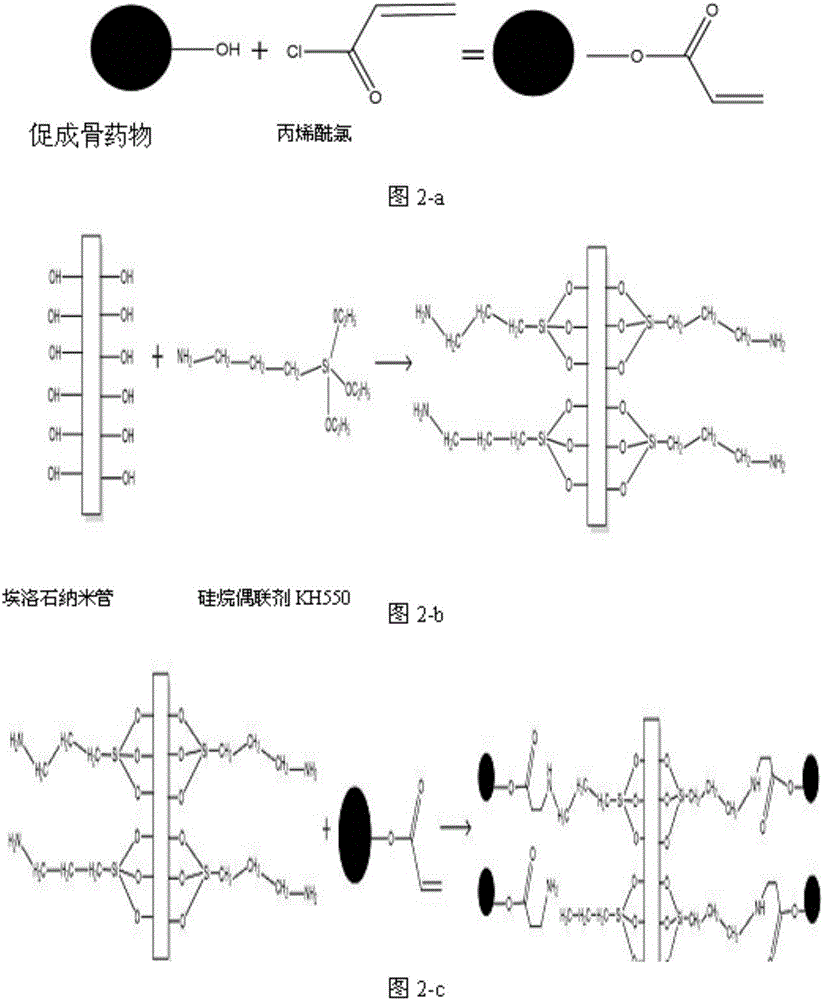

[0039] (1) Take 5g of halloysite nanotubes, add 200mL of toluene solvent to ultrasonically disperse evenly, add 5mL of KH550 under toluene reflux conditions at 120°C, and react for 12 hours to obtain modified halloysite nanotubes A;

[0040] (2) Take a certain amount of bone-promoting drug icariin to react with acryloyl chloride. The molar ratio of bone-promoting drug to acryloyl chloride is 1:1. After the reaction is carried out in an ice-water bath for 12 hours, the reaction product is purified and dried to obtain C;

[0041] (3) reacting A and C under certain conditions to obtain halloysite nanotubes D grafted with bone-promoting drugs on the surface, wherein the molar ratio of A to C is 1:2;

[0042] (4) Take a certain amount of the bone-promoting drug icariin and add it to N,N-dimethylformamide (DMF), stir and ultrasonically dissolve it to obtain a saturated solution;

[0043] (5) Mix 5 g of halloysite nanotubes D with a saturated solution containing 5 g of the bone-prom...

Embodiment 2

[0053] (1) Take 5g of halloysite nanotubes, add 200mL of toluene solvent to ultrasonically disperse evenly, add 25mL of KH550 under toluene reflux conditions at 120°C, and react for 12 hours to obtain modified halloysite nanotubes A;

[0054] (2) Take a certain amount of bone-promoting drug icariin to react with acryloyl chloride. The molar ratio of bone-promoting drug to acryloyl chloride is 1:1.5. After the reaction is carried out in an ice-water bath for 12 hours, the reaction product is purified and dried to obtain C;

[0055] (3) reacting A and C under certain conditions to obtain halloysite nanotubes D grafted with bone-promoting drugs on the surface, wherein the molar ratio of A to C is 2:3;

[0056] (4) Take a certain amount of the bone-promoting drug icariin and add it to N,N-dimethylformamide (DMF), stir and ultrasonically dissolve it to obtain a saturated solution;

[0057] (5) Get 5g of halloysite nanotube D and mix with the saturated solution of icariin, ultrason...

Embodiment 3

[0067] (1) Take 5g of halloysite nanotubes, add 200mL of toluene solvent to ultrasonically disperse evenly, add 15mL of KH550 under toluene reflux conditions at 120°C, and react for 12 hours to obtain modified halloysite nanotubes A;

[0068] (2) Take a certain amount of bone-promoting drug icariin to react with acryloyl chloride. The molar ratio of icariin to acryloyl chloride is 1:1.2. After the reaction is carried out in an ice-water bath for 24 hours, the reaction product is purified and dried. get C;

[0069] (3) A and C are reacted with a mixed solvent of methanol and water (methanol volume: water volume = 4:1) at 60°C to obtain halloysite nanotubes D grafted with icariin on the surface, wherein A and The molar ratio of C is 1:1.2;

[0070] (4) Take a certain amount of growth factor bone morphoprotein (BMP) and add it to deionized water, fully stir it to dissolve it to obtain its saturated solution;

[0071] (5) Mix 5 g of halloysite nanotube D with a saturated solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com