Precious metal loaded ZSM-5 molecular sieve, and preparation method and application thereof

A ZSM-5, precious metal technology is applied in the field of precious metal supported ZSM-5 molecular sieve and its preparation, and achieves the effects of simple preparation method, omission of roasting and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

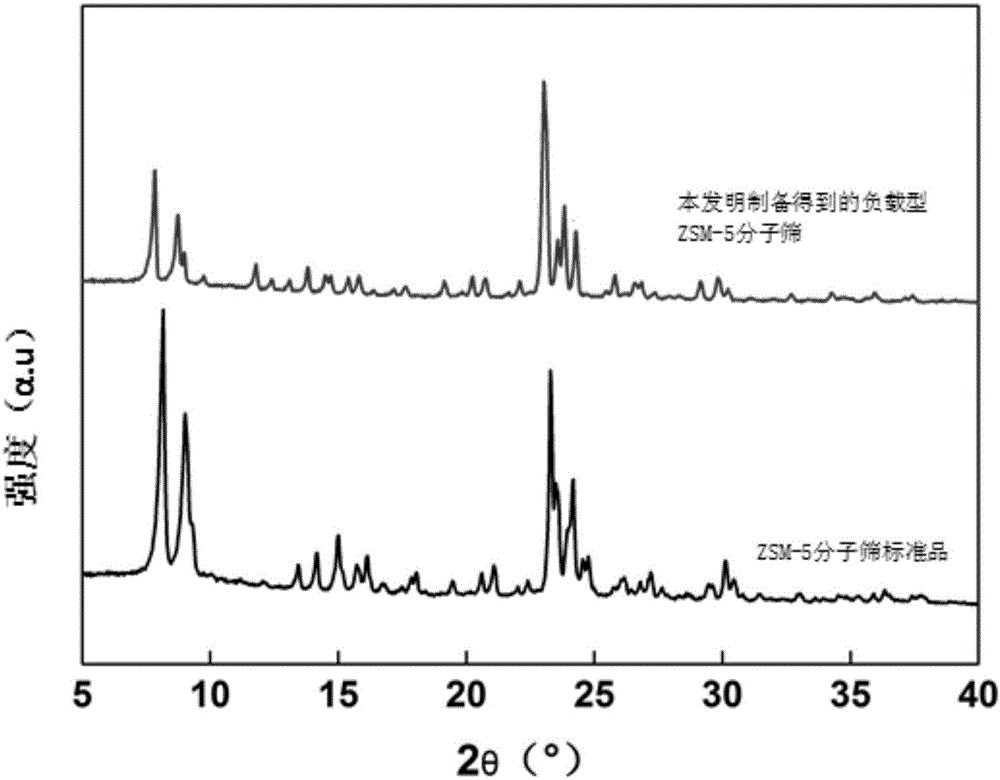

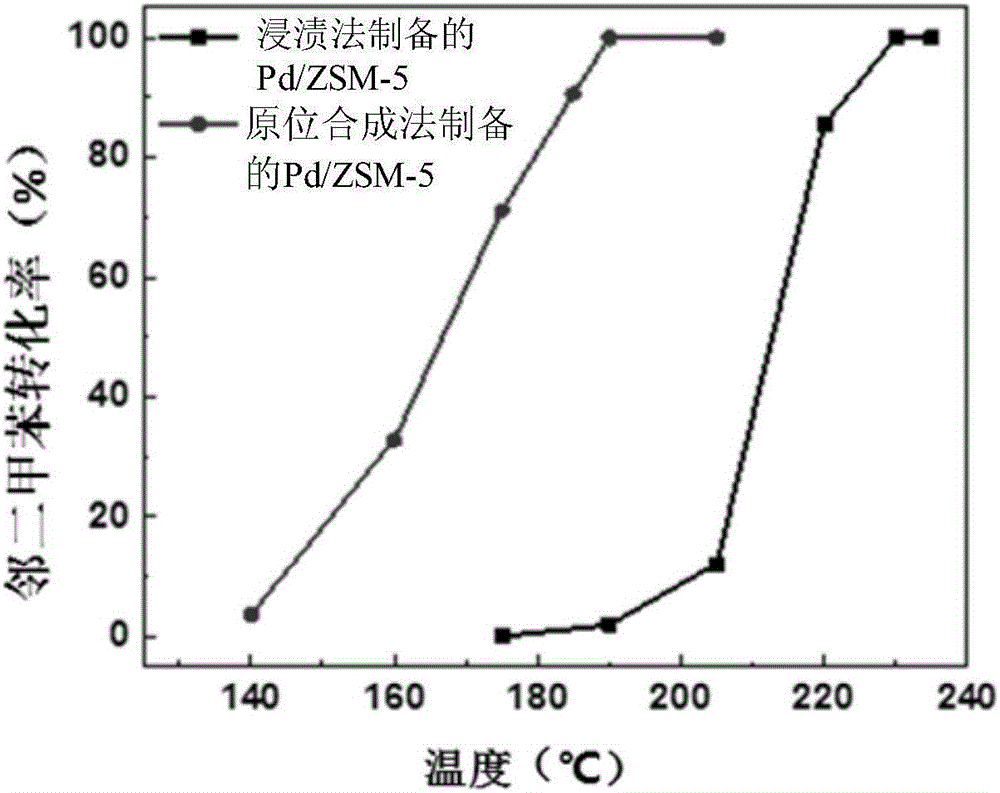

[0053] In the present invention, the in-situ synthesis of Pd-loaded ZSM-5 molecular sieves by the following method specifically includes the following steps:

[0054] (1) In a 200mL beaker, add 0.066g of sodium metaaluminate, 41.5g of deionized water, 24.5mL of tetra-n-propylammonium hydroxide (19.42%) and 15.6mL of palladium nitrate aqueous solution (1.4998×10 -3 g / ml), stirred at 25°C for 15min;

[0055] (2) Add 17.75 mL tetraethyl orthosilicate to the mixture obtained in step (1), and stir and mix at 25° C. for 5 h;

[0056] (3) The mixture obtained in step (2) was crystallized at 180° C. for 4 days in a reactor to obtain crystals, which were washed and dried to obtain Pd-loaded ZSM-5 molecular sieves.

Embodiment 2

[0058] In the present invention, in-situ synthesis of noble metal-supported ZSM-5 molecular sieves by the following method specifically includes the following steps:

[0059] (1) In a 200mL beaker, add 0.066g sodium metaaluminate, 13.2g deionized water, 13.5mL tetra-n-propylammonium hydroxide solution (concentration 15%) and 15mL palladium nitrate aqueous solution (2×10 -3 g / mL) was stirred and mixed for 30min at 20°C;

[0060] (2) Add 7 mL tetraethyl orthosilicate to the mixture obtained in step (1), and stir and mix at 20° C. for 10 h;

[0061] (3) The mixture obtained in step (2) was crystallized at 150° C. in a reaction kettle for 8 days to obtain a crystal, which was washed and dried to obtain a Pd-loaded ZSM-5 molecular sieve.

Embodiment 3

[0063] In the present invention, in-situ synthesis of noble metal-supported ZSM-5 molecular sieves by the following method specifically includes the following steps:

[0064] (1) In a 200mL beaker, add 0.066g of sodium metaaluminate, 52.8g of deionized water, 26.5mL of tetra-n-propylammonium hydroxide solution (concentration 25%) and 19.5mL of palladium nitrate aqueous solution (1×10 -3 g / mL) was stirred and mixed for 5 min at 30°C;

[0065] (2) Add 20 mL tetraethyl orthosilicate to the mixture obtained in step (1), and stir and mix at 35° C. for 3 h;

[0066] (3) The mixture obtained in step (2) was crystallized at 200° C. for 1 day in a reactor to obtain a crystal, which was washed and dried to obtain a Pd-loaded ZSM-5 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com