A treatment method for sucralose mother liquor wastewater after biodegradation pretreatment

A technology of sucralose and biodegradation, applied in the direction of biological water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of effluent water quality that is difficult to meet the standard and affect the ecological environment of water bodies, and meet the needs of environmental protection, Improve the growth rate of bacteria and the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

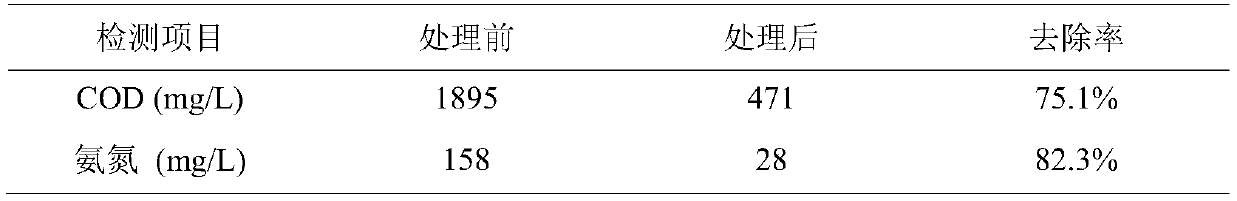

Embodiment 1

[0021] In this embodiment, a method for treating sucralose mother liquor wastewater after biodegradation pretreatment, the steps are as follows:

[0022] (1) isolate and obtain bacillus group from soil;

[0023] Put 100mL of distilled water in a beaker, add 0.6g of yeast powder, 1.5g of peptone, 0.8g of sodium chloride, and 2.2g of agar in sequence to make an LB plate, use an inoculation loop to pick up 0.5mg of soil sample on a 15ml LB plate, and draw a line Separate and culture in a constant temperature incubator at a temperature of 37°C for 12 hours to obtain bacillus groups, such as Bacillus subtilis, Bacillus licheniformis, Bacillus natto, Bacillus cereus, etc.;

[0024] (2) The bacillus group is expanded and cultivated to obtain a pulpy high-density bacillus group

[0025] Take 1g of the above-mentioned bacillus group and inoculate it into TB medium made by adding 10g yeast powder, 6g peptone, 0.25g glycerol, and 9g phosphate to 500mL distilled water for expansion, main...

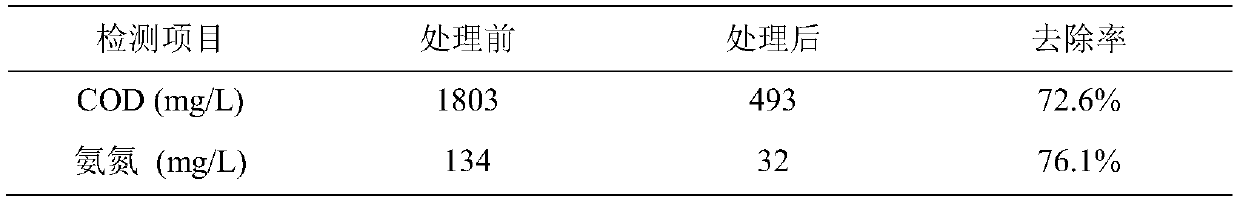

Embodiment 2

[0033] In this embodiment, a method for treating sucralose mother liquor wastewater after biodegradation pretreatment, the steps are as follows:

[0034] (1) isolate and obtain bacillus group from soil;

[0035] Put 100mL of distilled water in a beaker, add 0.4g of yeast powder, 1.2g of peptone, 0.8g of sodium chloride, and 1.8g of agar in sequence to make an LB plate, use an inoculation loop to pick up 0.8mg of soil samples on a 20ml LB plate, and draw a line Separate and culture in a constant temperature incubator at a temperature of 37°C for 14 hours to obtain bacillus groups, such as Bacillus subtilis, Bacillus licheniformis, Bacillus natto, Bacillus cereus, etc.;

[0036] (2) The bacillus group is expanded and cultivated to obtain a pulpy high-density bacillus group

[0037] Take 1.5g of the above-mentioned bacillus group and inoculate it into TB medium made of 500mL distilled water, 7g yeast powder, 5g peptone, 0.15g glycerol, and 8g phosphate for expansion, maintain pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com