MOF (metal-organic framework) composite material as well as preparation method and application thereof

A metal-organic framework and composite material technology, applied in the field of metal-organic framework composite materials, can solve the problems of non-selective regeneration, low adsorption capacity, difficulties, etc., and achieve the effects of mild conditions, improved adsorption, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

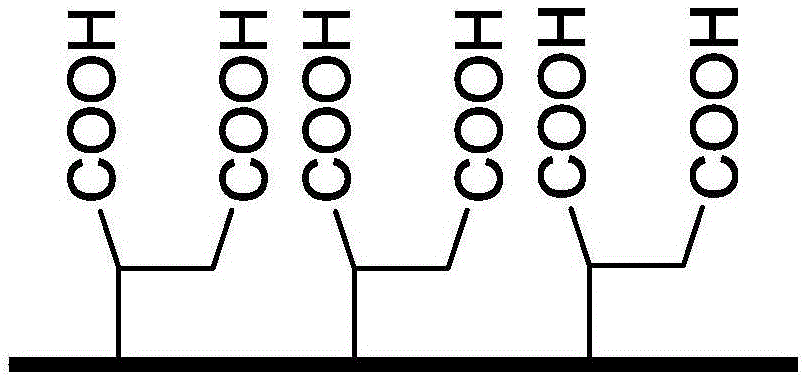

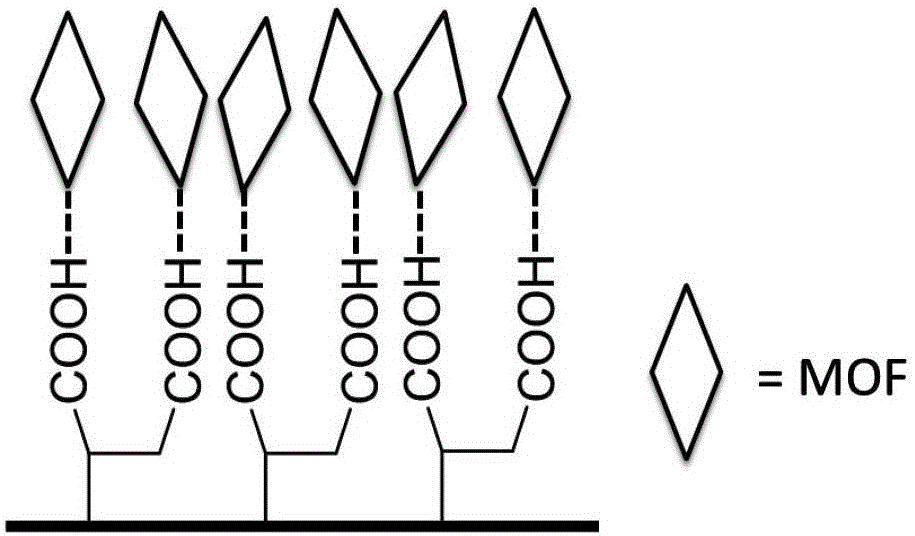

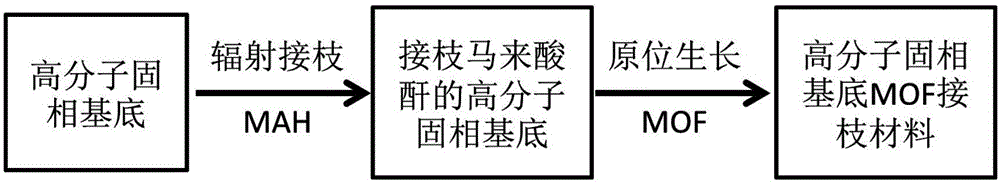

[0055] The present invention also provides a method for preparing the metal-organic framework composite material, comprising: mixing a polymer material substrate grafted with maleic anhydride, a metal salt, and a carboxyl-containing organic ligand in a solvent, and heating and reacting to obtain a metal Organic framework composite material; the carboxyl-containing organic ligand contains functional groups; the functional groups contain one or more of nitrogen, oxygen and sulfur elements.

[0056] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0057] According to the present invention, the polymer material substrate grafted with maleic anhydride is preferably prepared according to the following method: the polymer material substrate is irradiated to obtain the irradiated polymer material substrate; the maleic anhydride is heated and melted, Add the irradiated polymer material substrate under a protecti...

Embodiment 1

[0080] Take 10g of polyimide (PI) fiber material, wash it with acetone and dry it, put it into a closed container to evacuate it, put it into a radiation source for irradiation, the dose rate is 4kGy / h, and the absorbed dose is 80kGy.

[0081] Add maleic anhydride to a three-necked flask connected with a stirring paddle, and heat to melt it. Use a glass tube to pass through the reaction liquid below the liquid level, and pass through nitrogen. After 15 minutes, the irradiated base material was added into the flask, the reaction was stopped at 90° C. for 4 hours, and the solid product was filtered out. After the product is extracted, washed and dried, the base material of grafted maleic anhydride is obtained.

[0082] Add 2 parts of copper sulfate and 1 part of 1,2,3,5-pyrene tetracarboxylic acid into deionized water, stir and dissolve, then add to the reaction kettle, add the above-mentioned grafted maleic anhydride base material to it, and seal at 90°C Response 3 days. Rep...

Embodiment 2

[0085] Take a polyethylene terephthalate (PET) non-woven fabric with a thickness of 0.65 mm and an area of about 20 × 50 mm, wash it with acetone and dry it, then put it into a closed container, and add a mass fraction of 50% maleic anhydride tetrahydrofuran The solution is submerged in the base material, sealed and placed in a radiation source for irradiation with a dose rate of 3kGy / h and an absorbed dose of 60kGy. The irradiated product is extracted, washed and dried to obtain the base material of grafted maleic anhydride.

[0086] Dissolve 3 parts of zirconium chloride and 2 parts of 2-aminoterephthalic acid in a mixed solution of N,N-dimethylformamide (DMF) and hydrochloric acid (V DMF :V HCl =15:1), stirring and dissolving, adding to the reactor, adding the above-mentioned grafted maleic anhydride base material to it, and sealing at 80°C for 12 hours. Ultrasonic cleaning was performed twice with DMF and ethanol respectively, the material was soaked in ethanol, and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com