Biology base air source and flame retardant polyolefin compound formed by biology base air source

A bio-based, polyolefin technology, applied in the field of flame retardant polyolefin compounds, can solve problems such as unsolved problems, achieve the effects of light mechanical properties, good thermal stability, and improved flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Firstly, pre-treat the base. The method is as follows: immerse the base in a 1% weight solution of tetrabutyl titanate (isopropanol as the solvent, 2.5 times the amount of the base), treat it for 2h, dry and set aside . (The bases used in the formulas of the examples are all pretreated)

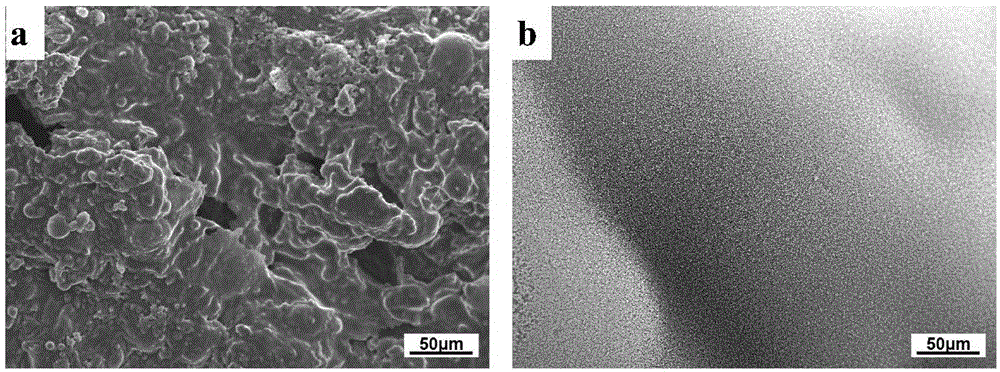

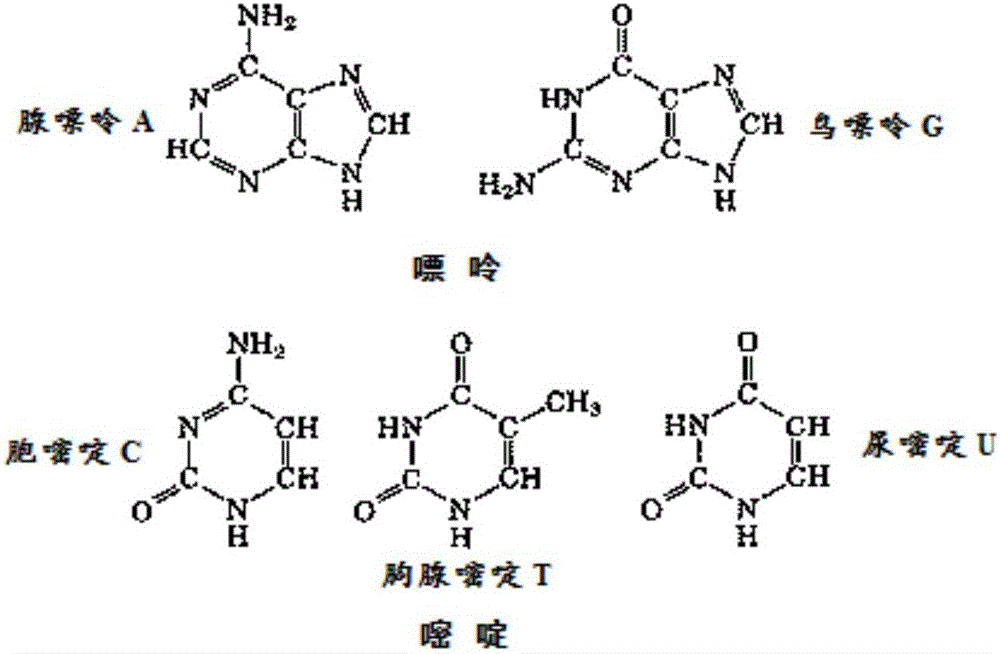

[0023] 800g polypropylene, 180g ammonium polyphosphate / pentaerythritol / pretreated base C (APP / PER / C) flame retardant (where APP: PER: C=3:1:1), 10g montmorillonite, 5g Stearic acid, 5g [β-(3,5-di-tert-butyl-4-hydroxy)phenylpropionic acid] pentaerythritol ester. Use a high-speed mixer to mix uniformly, extrude the obtained mixture in a screw extruder at 170-190°C, and obtain a flame-retardant polypropylene composite through injection molding and cooling. The flame-retardant properties of the flame-retardant polypropylene material: LOI is 32.0%, and it can pass the UL94V-0 level test. The residual carbon after combustion is tested by SEM and compared with the sample without bases. See fig...

Embodiment 2

[0025] Firstly, pre-treat the base. The method is as follows: immerse the base in a 1% weight solution of tetrabutyl titanate (isopropanol as the solvent, 2.5 times the amount of the base), treat it for 2h, dry and set aside .

[0026] 800g polypropylene, 180g ammonium polyphosphate / dipentaerythritol / pretreated base C (APP / DPER / C) flame retardant (where APP: DPER: C=2:1:1), 10g molecular sieve, 5g hard Calcium fatty acid, 5g tris(2,4-di-tert-butylphenyl) phosphite. Use a high-speed mixer to mix uniformly, extrude the obtained mixture in a screw extruder at 170-190°C, and obtain a flame-retardant polypropylene composite through injection molding and cooling. The flame-retardant properties of the flame-retardant polypropylene material: LOI is 32.0%, and it can pass the UL94V-0 level test.

Embodiment 3

[0028] Firstly, the base is pretreated, the method is as follows: the base is immersed in a 2% by weight aminopropyltriethoxysilane solution (solvent ethanol: water = 9:1, the amount is 2.5 times the base) 3h, dry and set aside.

[0029] 800g polypropylene, 180g ammonium polyphosphate / dipentaerythritol / pretreated base U (APP / DPER / U) flame retardant (where APP: DPER: U = 2:1:1), 10g hydrotalcite, 5g Magnesium stearate, 5g [β-(3,5-di-tert-butyl-4-hydroxy)phenylpropionic acid] pentaerythritol ester. Use a high-speed mixer to mix uniformly, extrude the obtained mixture in a screw extruder at 170-190°C, and obtain a flame-retardant polypropylene composite through injection molding and cooling. The flame-retardant properties of the flame-retardant polypropylene material: LOI is 31.6%, and it can pass the UL94V-0 level test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com