Insulating copolyamide 6T composite material with high thermal conductivity and preparation method thereof

A technology of copolyamide and composite materials, which is applied in the field of materials, can solve the problems of limited application, low thermal conductivity of high temperature resistant polyamide, etc., and achieve the effect of low price, good insulation performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

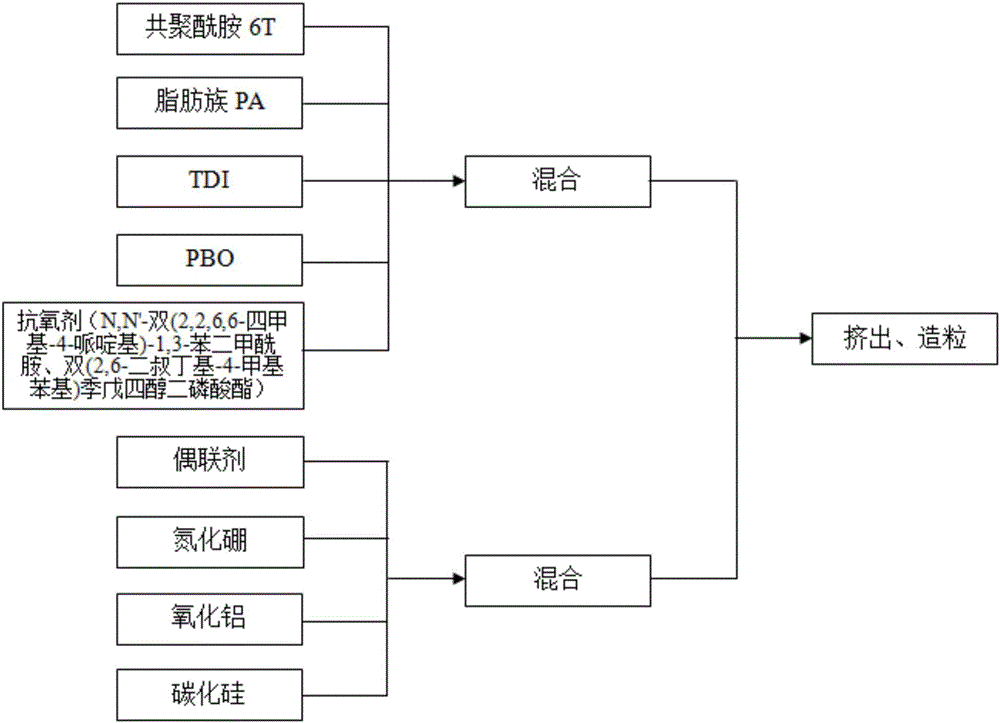

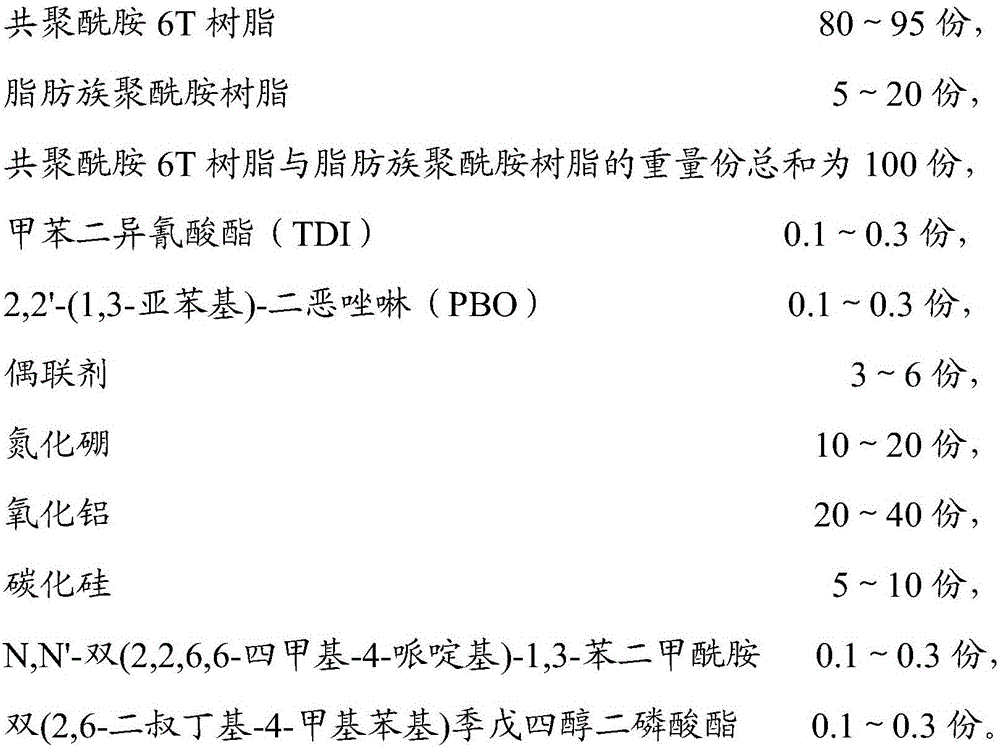

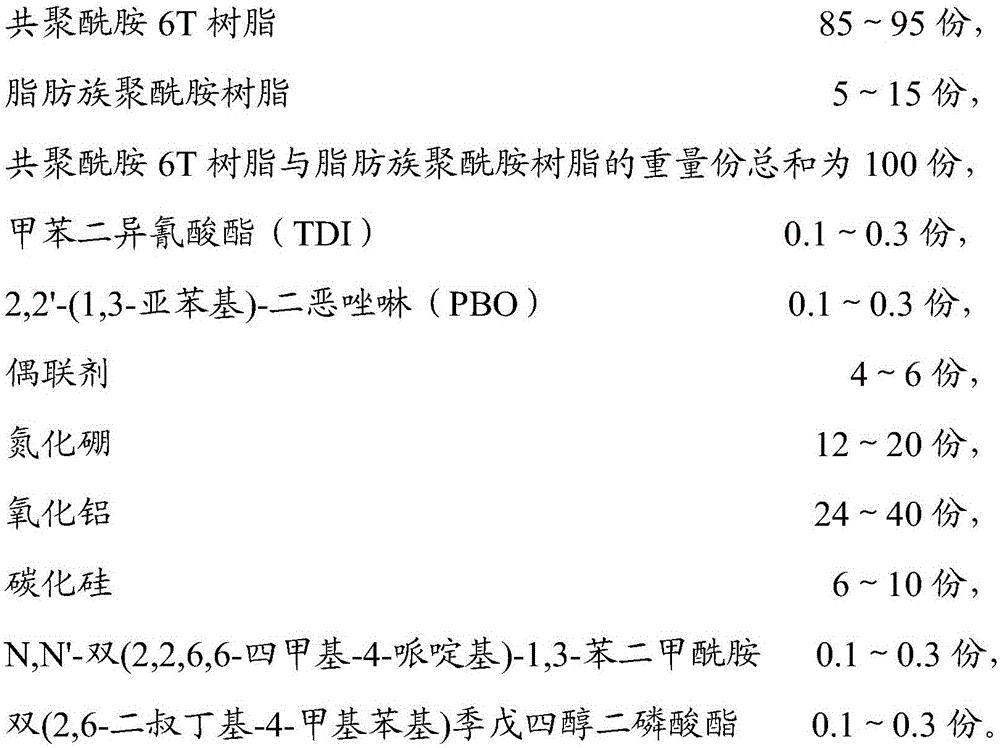

Method used

Image

Examples

Embodiment 1

[0073] The copolyamide 6T resin used in the present embodiment is polyamide 6T / 610 resin (PA6T / 610), and its raw material composition and synthesis steps are as follows:

[0074] (1) Vacuum-dried monomer 1: 1mol hexamethylenediamine, 0.6mol terephthalic acid, 0.4mol sebacic acid are added to the stirred polymerization reactor, and 4% of the total weight of monomer 1 is added simultaneously. Esteramide, 1.5% benzoic acid, 0.2% N,N'-di(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL water as The medium for mass transfer and heat transfer; then evacuate for 5 minutes, pass nitrogen for 5 minutes, and circulate like this for 6 times, so that the reactant exists in the environment under nitrogen protection, and the system pressure in the stirred polymerization reactor is controlled to be 0.3MPa;

[0075](2) within 3 hours, heat the stirred polymerization reactor airtight to 275°C at a uniform speed, adjust the stirring speed of the stirred polymerization reactor to 40...

Embodiment 2

[0086] The copolyamide 6T resin used in the present embodiment is polyamide 6T / 612 resin (PA6T / 612), and its raw material composition and synthesis steps are as follows:

[0087] (1) Add monomer 1 after vacuum drying: 1mol hexamethylenediamine, 0.6mol terephthalic acid, 0.4mol dodecanedioic acid into the stirred polymerization reactor, and add 4% of the total weight of monomer 1 at the same time Polyesteramide, 1.5% benzoic acid, 0.2% N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL Water is used as the medium for mass transfer and heat transfer; then vacuumize for 5 minutes, and pass nitrogen for 5 minutes, and circulate like this 6 times, so that the reactant exists in the environment under nitrogen protection, and the system pressure in the stirred polymerization reactor is controlled to be 0.3MPa;

[0088] (2) within 3 hours, heat the stirred polymerization reactor airtight to 275°C at a uniform speed, adjust the stirring speed of the stirred polymeri...

Embodiment 3

[0098] The copolyamide 6T resin used in the present embodiment is polyamide 6T / 66 resin (PA6T / 66), and its raw material composition and synthesis steps are as follows:

[0099] (1) Vacuum-dried monomer 1: 1mol hexamethylenediamine, 0.6mol terephthalic acid, 0.4mol adipic acid are added to the stirred polymerization reactor, and 4% of the total weight of monomer 1 is added simultaneously. Esteramide, 1.5% benzoic acid, 0.2% N,N'-di(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL water as The medium for mass transfer and heat transfer; then evacuate for 5 minutes, pass nitrogen for 5 minutes, and circulate like this for 6 times, so that the reactant exists in the environment under nitrogen protection, and the system pressure in the stirred polymerization reactor is controlled to be 0.3MPa;

[0100] (2) within 3 hours, heat the stirred polymerization reactor airtight to 275°C at a uniform speed, adjust the stirring speed of the stirred polymerization reactor to 40r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com