A kind of color enhancer of oily ceramic bleed hair color ink and its preparation and usage

A color enhancer and ink technology, applied in the directions of ink, application, household appliances, etc., can solve the problems of unstable color development of metal oxides, inability to develop color, affecting the uniformity of color development, etc. Increased vividness, stable and even hair color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of oily antimony-based chromogenic ink color enhancer raw materials

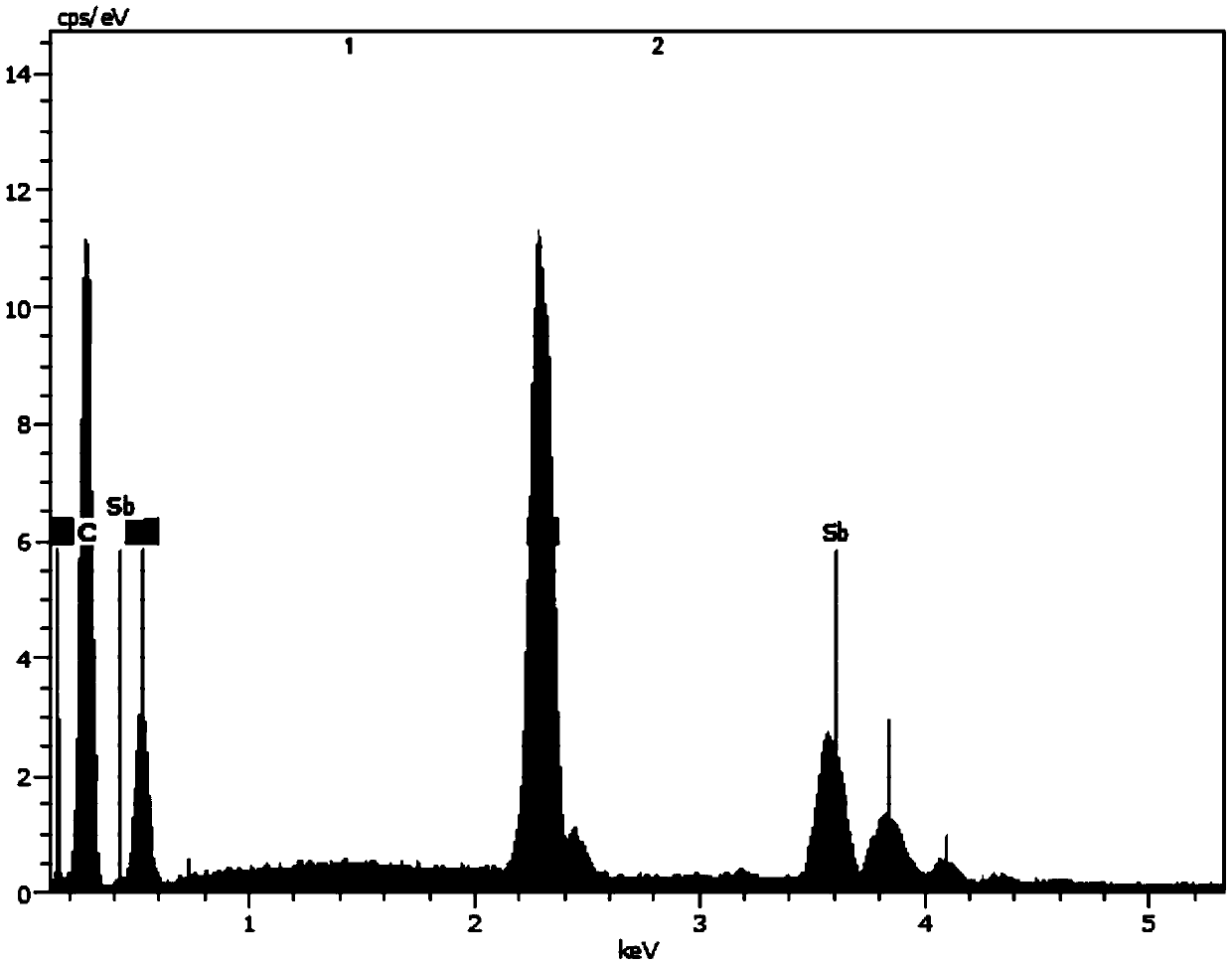

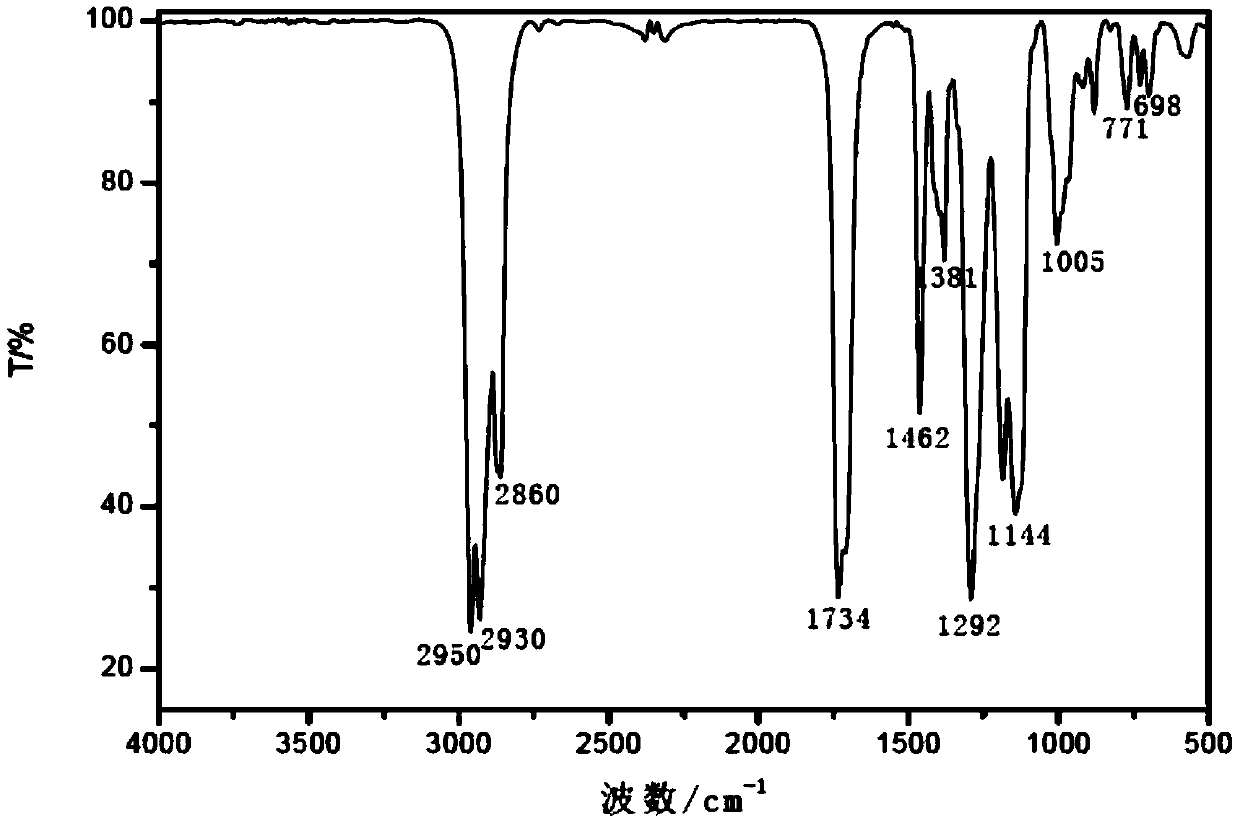

[0025] (1) The preparation of three (isooctyl thioglycolate) antimony: add 61.30g (0.3mol) isooctyl thioglycolate, 13.25g (0.045mol) antimony trioxide and 45g water in the round bottom flask, magnetic stirring, Reflux reaction at 80°C for 2 hours, after cooling, separate the liquid through a separatory funnel to remove the upper aqueous phase; the lower organic phase is distilled under reduced pressure by a circulating water vacuum pump to remove the water remaining in the oil phase to obtain an oily antimony-based color-developing ink color enhancer Raw materials - Tris (isooctyl thioglycolate) antimony YSb1, set aside. Then test its elemental analysis and infrared spectrum, get respectively figure 1 and figure 2 .

[0026] figure 1 It is the EDS elemental analysis diagram of tris(isooctyl thioglycolate)antimony, according to the EDS elemental analysis, the content of anti...

Embodiment 2

[0035] Embodiment 2 Preparation of Oily Titanium Series Chromogenic Ink Color Enhancer Raw Materials

[0036] (1) Add 284g (1mol) of tetraisopropyl titanate and 288g (2mol) of isooctanoic acid into a round bottom flask, stir at room temperature for 1 hour, reflux at 100°C for 2 hours, remove small molecules under reduced pressure after the reaction is completed, and cool , to obtain viscous liquid titanium isooctanoate isopropoxy compound ((C 3 h 7 O) m Ti(OOCC 7 h 15 ) n ), which is oily titanium series chromogenic ink color enhancer raw material YT1, for subsequent use.

[0037] (2) Add 340 g (1 mol) of tetrabutyl titanate and 432 g (3 mol) of isooctanoic acid into a round-bottomed flask, stir at room temperature for 1 hour, reflux at 140°C for 2 hours, remove small molecules under reduced pressure after the reaction is completed, and cool. Obtain viscous liquid titanium isooctanoate butoxylate ((C 4 h 9 O)m Ti(OOCC 7 h 15 ) n ), which is oily titanium series chro...

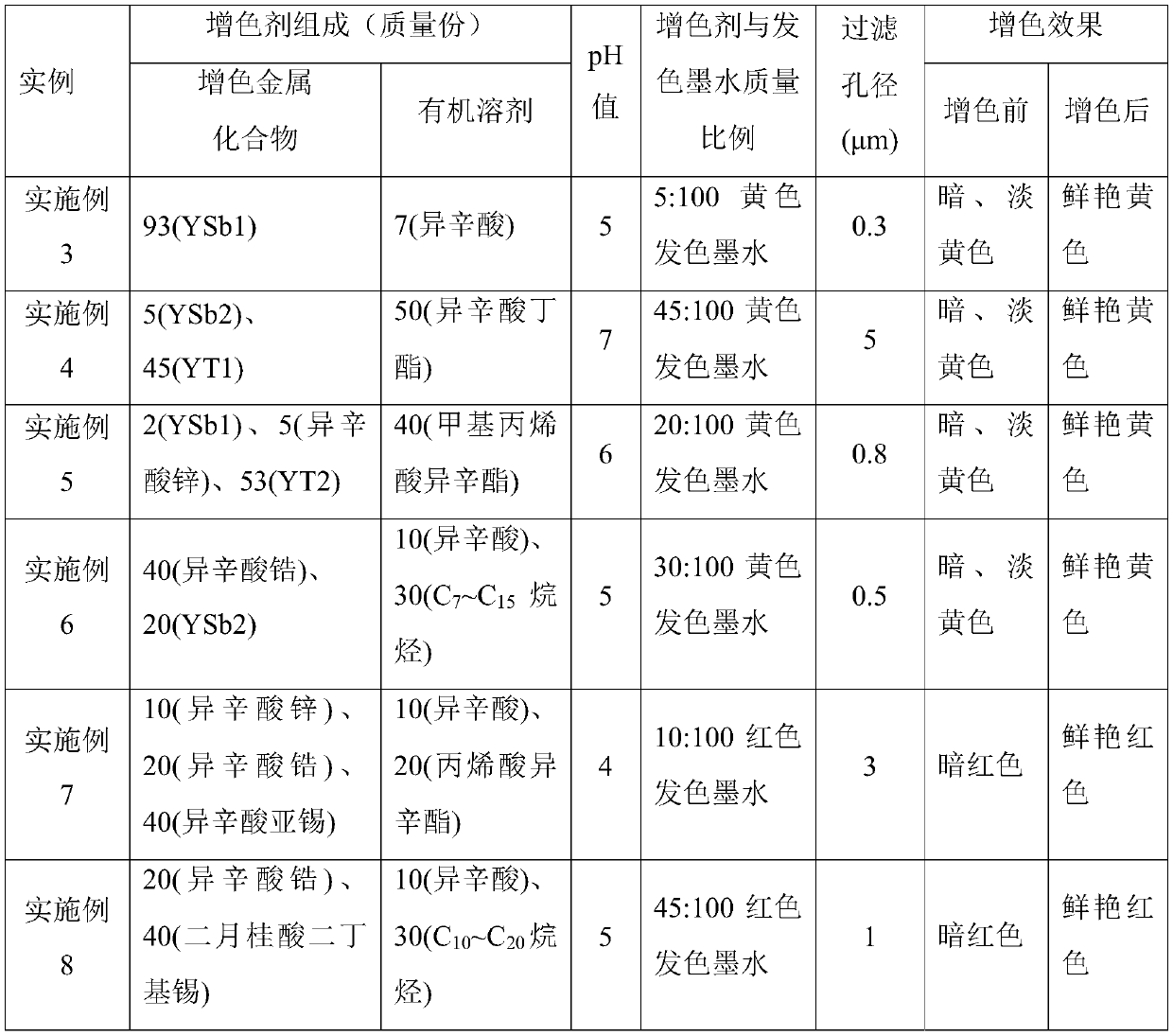

Embodiment 3

[0040] According to the ratio in Table 1, 93 parts by mass of YSb1 and 7 parts by mass of isooctanoic acid were uniformly mixed at room temperature to obtain 100 parts by mass of oily ceramic bleed color ink color enhancer, and its pH value was measured to be 5. Then take 5 parts by mass of it, mix it with 100 parts by mass of the yellow chromogenic ink at room temperature, filter through a filter hole of 0.3 μm, and print the filtrate and the pure yellow chromogenic ink on the ceramic body or glaze by digital inkjet respectively Above, after firing at a high temperature of 650°C for 4 hours, observe the ink color development effect before and after the color enhancement of the ceramic body or glaze after cooling. The experimental results are listed in the last column of Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com