Method for hydrolyzing thick mash of agricultural and forest biomass raw material to produce glycose

A technology of biomass raw materials and cellulosic raw materials, which is applied in the resource utilization of agricultural and forestry biomass raw materials and in the field of biomass chemical industry, can solve the problems of enzymatic hydrolysis and saccharification of difficult-to-concentrate mash, and achieve rich active groups, narrow distribution, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

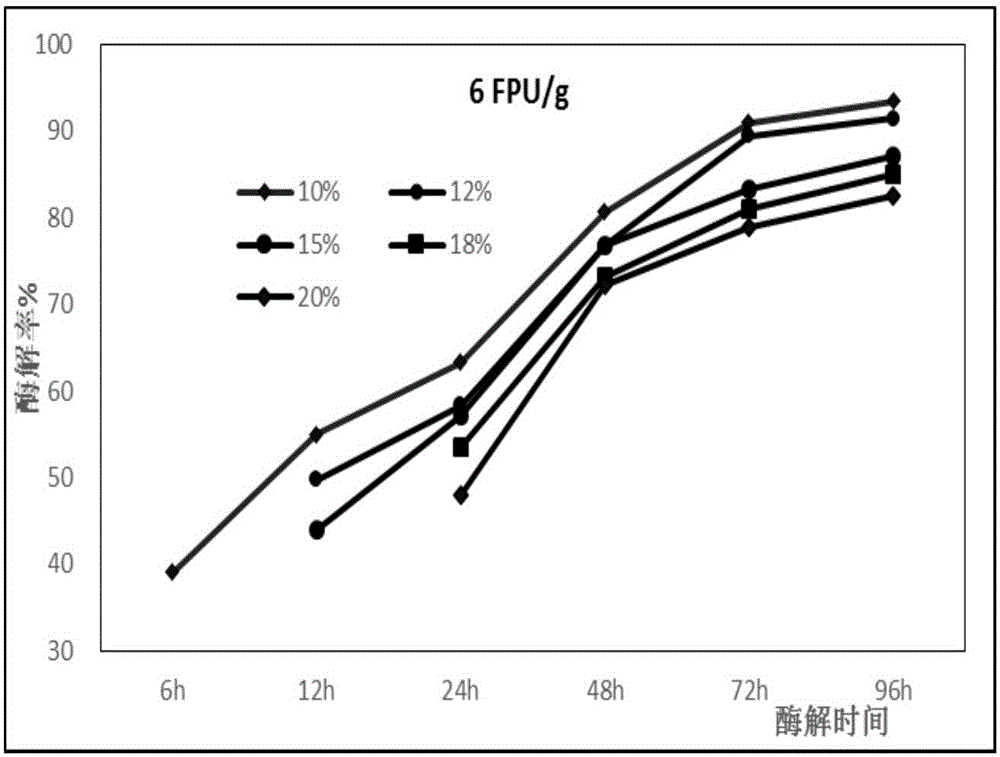

Image

Examples

Embodiment 1

[0029] Sieve the collected air-dried bagasse to 5-20mm.

[0030]Then, 100 g of the bagasse and 1.4 kg of industrial glycerin were placed in a 5-liter three-neck flask, heated to 240° C. at a stirring rate of 250 rpm, and then kept for 10 minutes. After the reaction, cool to 100°C, add 1.5kg of boiling water for washing, stir mechanically, and continue cooling down to 50-60°C. Since glycerin is relatively dense and has a low viscosity, some removed lignin often sticks to the surface of the material and is not completely dissolved in glycerin. Therefore, boiling water is added to form glycerin aqueous solution, and mechanical stirring is added at the same time, which is more conducive to the dissolution of lignin. Then use the G4 sand core funnel to suction filter, then use tap water to elute and suction filter 2 times (each 2kg); content of 26%, lignin content of 13%, glycerin residue is 0.39% of the dry weight of the matrix, and the hemicellulose and lignin removal rates are ...

Embodiment 2

[0033] The collected bagasse is air-dried and sieved to collect materials within the range of 5-20mm.

[0034] Then, 100g of the above-mentioned pulverized bagasse and 1.0kg of the above-mentioned industrial glycerin are placed in a 5 liter three-necked flask cooking device, add 1ml of concentrated sulfuric acid (the amount of sulfuric acid added is 0.1%, w / v) and heat up, stir at 250rpm, and heat up to Keep warm and cook for 30 minutes at 230°C. After the reaction, cool to 100°C, add 1.5kg of boiling water, stir mechanically, cool down to 50-60°C, use G4 sand core funnel for suction filtration, filter residue is then eluted with 2kg tap water for suction filtration, and G4 sand core funnel for suction filtration once; The filter residue is glycerol crude cellulose, its quality is bagasse before pretreatment 57.9%, its cellulose content is 64%, hemicellulose content is 6.61%, lignin content is 18.14%, and glycerin residue is matrix dry weight 22.3%, half The removal rates of ...

Embodiment 3

[0037] Sieve the collected air-dried bagasse to 5-20mm.

[0038] Then, place the above-mentioned bagasse 100g and 1.4kg of the above-mentioned industrial glycerin solution in a cooking device, add 3g of sodium hydroxide (0.2% sodium hydroxide, w / w), stir and heat up at 200rpm, cook at 240°C for 10 minute. After the reaction, cool to 100°C, add 1.5kg of boiling water, stir mechanically, cool down to 50-60°C, filter with G4 sand core funnel, elute the filter residue with tap water at normal temperature, and suction filter with G4 sand core funnel twice (each time 2kg ); filter residue is glycerol crude cellulose, and its quality is 64% of bagasse before reaction, and its cellulose content is 58%, and hemicellulose content is 28%, lignin content 10%, and glycerin residue is matrix dry weight 0.47%, Correspondingly, the removal rates of hemicellulose and lignin were 20% and 70%, respectively. The filtrate is the glycerol treatment solution, which contains obvious glycerol glycos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com