Surface treatment process for blackened copper foil

A surface treatment and blackening copper technology, which is applied in the surface treatment process of copper foil and the surface treatment process of blackened copper foil, can solve the problems of increased density of copper foil, side erosion, and decrease of denseness of copper foil. Achieve good corrosion resistance and etching performance, simple and easy process, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

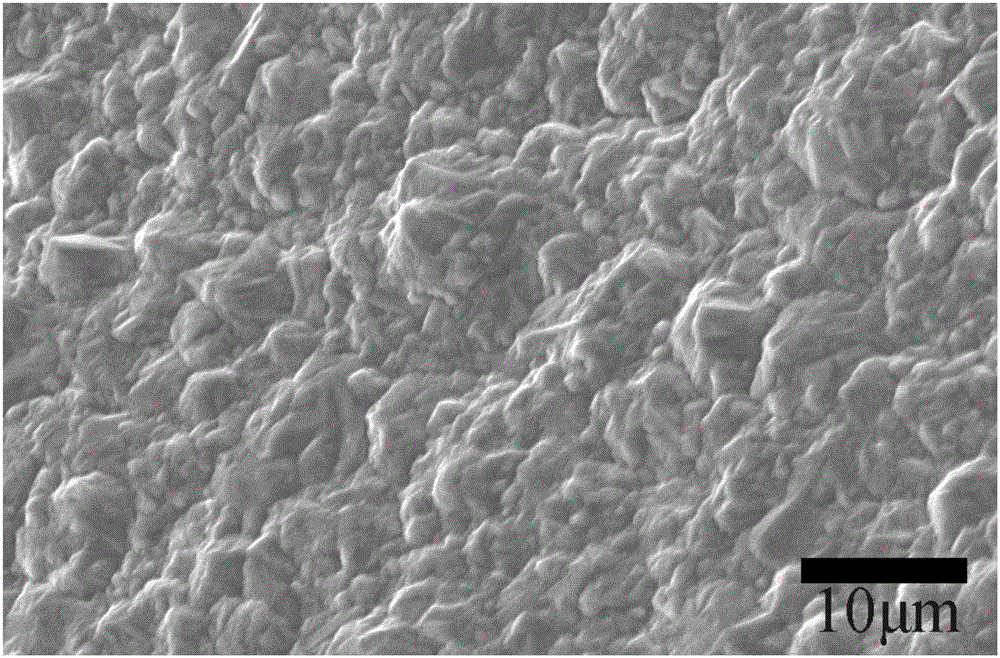

[0032] A surface treatment process of blackened copper foil, which uses 12 μm electrolytic copper foil as an electrode, and specifically goes through the following steps:

[0033] 1) Coarsening: Dissolve copper sulfate and nickel sulfate in water, then add sulfuric acid to it, and mix well to form a prepared roughening solution. Place copper foil in the roughening solution for electroplating. The control process parameters are: Cu 2+ 16g / L, Ni 2+ 5g / L,H 2 SO 4 220g / L, temperature 20℃, current density 32A / dm 2 , plating time 15s;

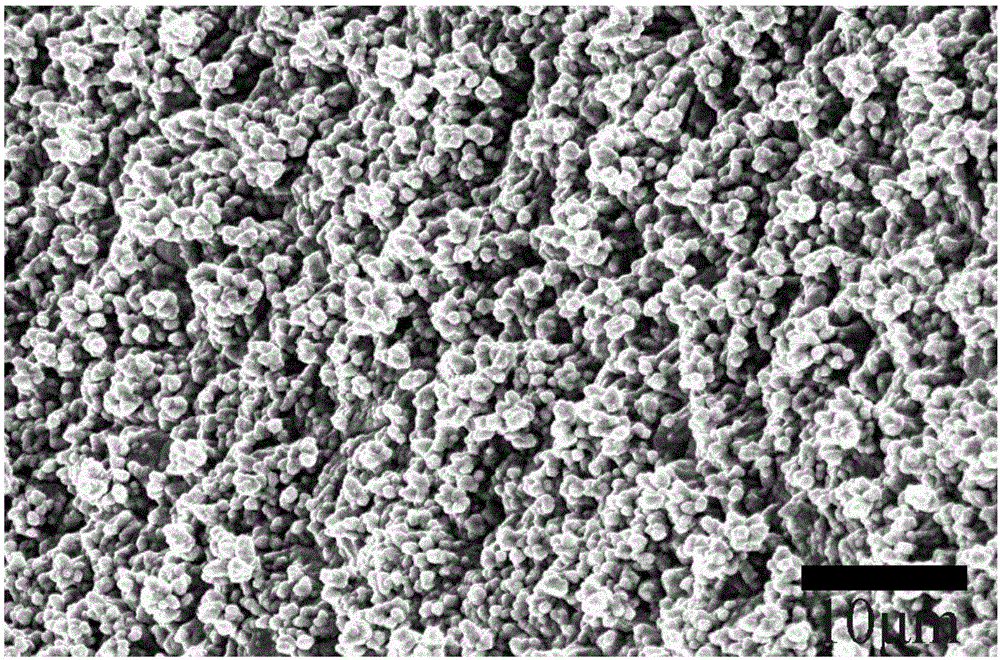

[0034] 2) Blackening: Dissolve the additives potassium tartrate, copper sulfate, and zinc sulfate in water respectively, and dissolve cobalt sulfate in water, and then add all the solutions to the additive solution and mix evenly and keep stirring to adjust the pH value. The control parameters are as follows: Cu 2+ 7g / L, Zn 2+ 4g / L, Co 2+ 20g / L, pH 6.5, potassium tartrate 67g / L, temperature 42℃, current density 5A / dm 2 , plating time 10s;

...

Embodiment 2

[0039] The difference between this example and Example 1 is that 18 μm LP copper foil is used as the electrode, and the process parameters of each step are controlled as follows:

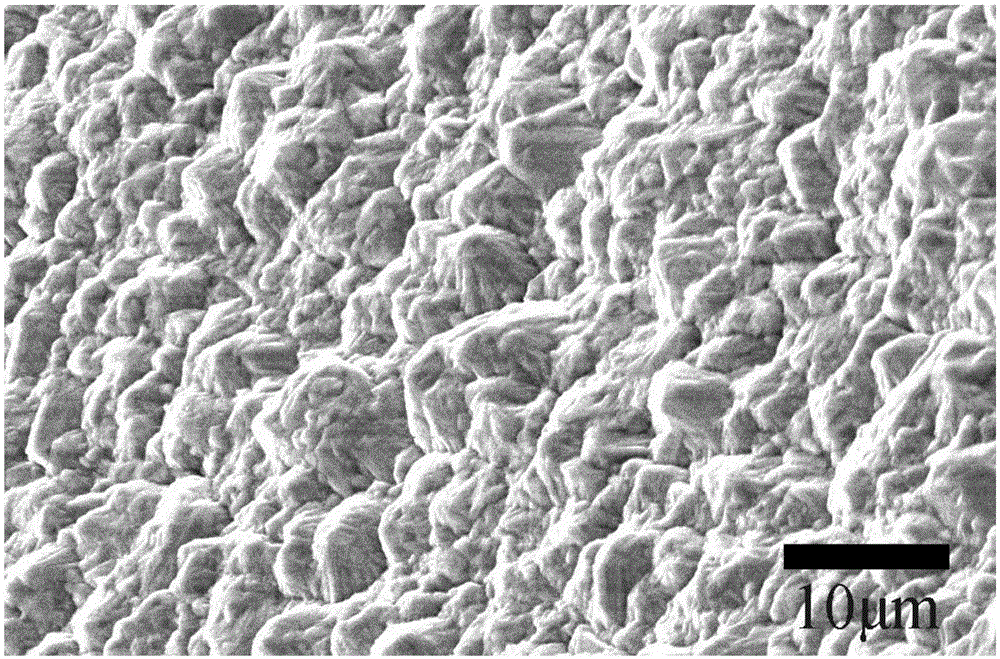

[0040] 1) Coarsening: Cu 2+ 20g / L, Ni 2+ 7g / L,H 2 SO4 150g / L, temperature 34℃, current density 26A / dm 2 , Plating time 8s.

[0041] 2) Blackening: Cu 2+ 10g / L, Zn 2+ 6g / L, Co 2+ 8g / L, Ni 2+ 8g / L, pH 5.0, tartaric acid 5g / L, temperature 38℃, current density 12A / dm 2 , Plating time 8s.

[0042] 3) Anti-oxidation: Cr 6+ 3g / L, Zn 2+ 3.5g / L, K 4 P 2 o 7 120g / L, PH 9.5, temperature 32°C, current density 5A / dm 2 , plating time 2s.

[0043] 4) Silane coupling agent: 3-aminopropyltrimethoxysilane 2g / L, temperature 30°C, treatment time 3s.

[0044] 5) Drying: the temperature is 220°C, and the processing time is 4s.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is that the process parameters of each step are controlled as follows:

[0047] 1) Coarse Cu 2+ 26g / L, Ni 2+ 8g / L, H 2 SO 4 120g / L, temperature 36℃, current density 20A / dm 2 , Plating time 5s.

[0048] 2) Blackening: Cu 2+ 20g / L, Zn 2+ 10g / L, Co 2+ 10g / L, Ni 2+ 20g / L, PH 4.2, potassium citrate 10g / L, ammonium citrate 25g / L, temperature 30°C, current density 20A / dm 2 , Plating time 12s.

[0049] 3) Anti-oxidation: Cr 6+ 6g / L, Zn 2+ 5g / L, K 4 P 2 o 7 155g / L, PH 9.2, temperature 29℃, current density 10A / dm 2 , Plating time 1.6s.

[0050] 4) Silane coupling agent: 3-aminopropyltriethoxysilane 3g / L, temperature 26°C, treatment time 4s.

[0051] 5) Drying: the temperature is 100°C, and the processing time is 6s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com